Additive for physical straw pulping and use method thereof

An auxiliary and physical technology, which is applied in pulping of cellulose raw materials, anti-foaming pulping process, non-woody plant/crop pulp, etc., can solve the problems of high cost and unsatisfactory pulping and finishing effect of straw biomass, etc. Achieve the effects of saving additives, reducing water consumption in pulping, and reducing the amount of additives used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

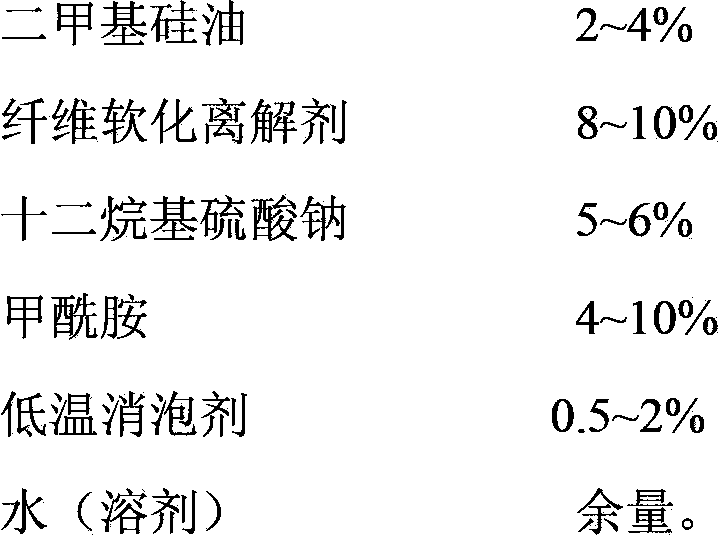

[0036] An auxiliary agent for straw physical pulping, which is composed of the following components by weight percentage:

[0037]

[0038] After the above components are mixed, the auxiliary agent (and mother liquor) for straw physical pulping is diluted 10 times, and used as a softening auxiliary agent for preparing semi-chemical mechanical pulp from dry rice straw, and the diluted auxiliary agent is sprayed per ton of straw Agent 60kg, spray frequency 60Kg / hour. The degree of disintegration of the obtained rice straw pulp is 25.05°S. According to the market price, the cost of additives is 80-90 yuan for each ton of straw mechanical pulp produced.

[0039] As a comparative test, tap water was used as a control, 60kg of water was sprayed per ton of straw, and the spray frequency was 60Kg / hour. The degree of disintegration of the obtained rice straw pulp was 14.01°S, and more than 35% of the rice straw pulp floated on the water surface and could not be mixed with the chemi...

Embodiment 2

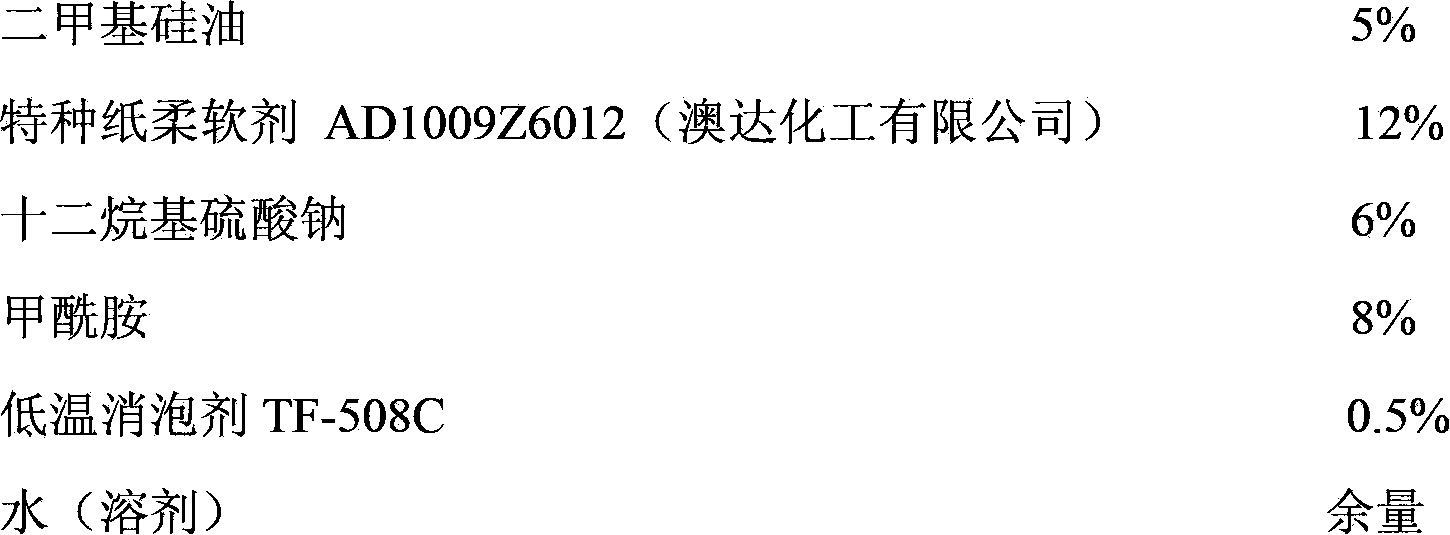

[0041] An auxiliary agent for straw physical pulping, which is composed of the following components by weight percentage:

[0042]

[0043] After the above components are mixed, the auxiliary agent (and mother liquor) for straw physical pulping is diluted 4 times, and it is used as a softening auxiliary agent for processing fresh wheat straw to prepare semi-chemical mechanical pulp. The diluted auxiliary agent is sprayed per ton of straw 30Kg, the spray frequency is 30Kg / hour. The degree of disintegration of the obtained wheat straw pulp is 27.03°S. According to the market price, the cost of additives is 95-110 yuan for producing 1 ton of straw mechanical pulp products.

[0044] As a comparative test, special paper softener AD1009Z6012 was used as a control, 30kg of water was sprayed per ton of straw, and the spray frequency was 30Kg / hour. For every ton of straw mechanical pulp produced, the cost of additives is 200~220 yuan; the degree of percussion of the obtained wheat ...

Embodiment 3

[0046] An auxiliary agent for straw physical pulping, which is composed of the following components by weight percentage:

[0047]

[0048]After the above components are mixed, the auxiliary agent (and mother liquor) for straw physical pulping is obtained. After the auxiliary agent is mixed, the mother liquor (that is, the above formula auxiliary agent) is diluted 20 times and used as a semi-chemical mechanical pulp for processing fresh reed straw. softening additives, 50Kg of diluted additives are sprayed per ton of straw, and the spraying frequency is 50Kg / hour.

[0049] The degree of disintegration of the obtained reed straw pulp is 21.6°S. According to the market price, the cost of additives is 90 yuan for the production of 1 ton of straw mechanical pulp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com