Preparation process for tetrabutyl urea

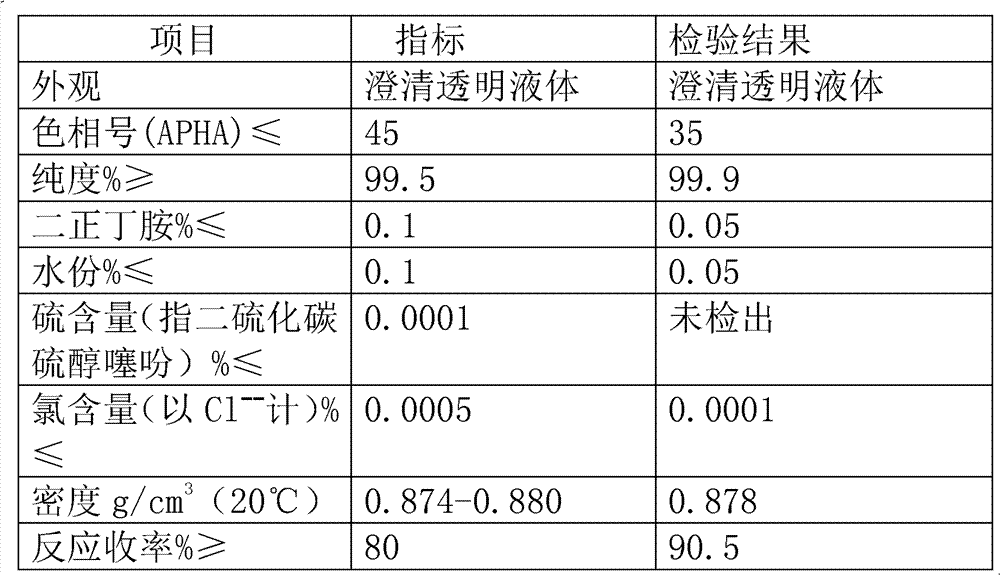

A technology of tetrabutylurea and preparation process is applied in the preparation of urea derivatives, the preparation of organic compounds, organic chemistry, etc., and can solve the problems of only 80%-85% yield of finished products, many by-products, and difficult industrialization. , to achieve the effect of cheap raw materials, good product quality and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

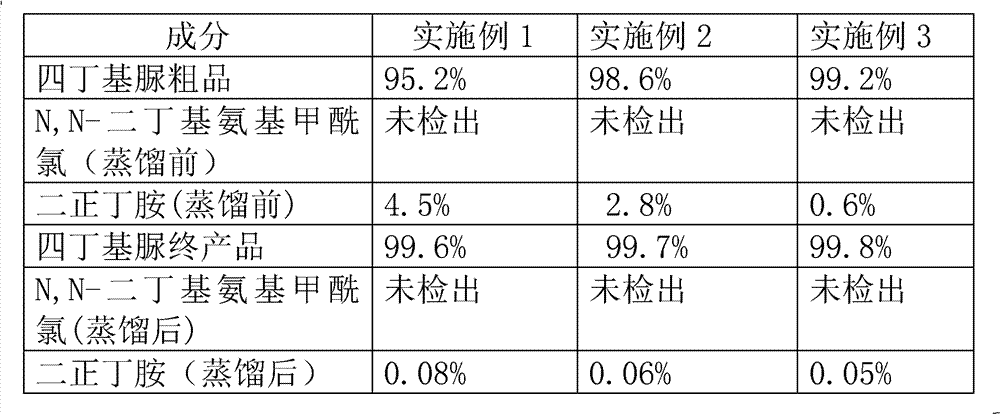

Embodiment 1

[0018] (1), add di-n-butylamine, phosgene and 20% sodium hydroxide solution in a molar ratio of 2: 1: 2 in a reaction vessel;

[0019] (2), the acylation reaction temperature is 60°C, and the acylation reaction time is 5 hours, and the crude product of tetrabutylurea is obtained;

[0020] (3) After the crude tetrabutylurea was left to stand for 30 minutes, the mother liquid water in the lower layer was separated, and the crude tetrabutylurea was distilled at a vacuum degree of -0.092MPa and a kettle temperature of 200°C to obtain the final product of tetrabutylurea .

Embodiment 2

[0022] (1), add di-n-butylamine, phosgene and 20% sodium hydroxide solution in a molar ratio of 2: 1.05: 2.1 in the reaction vessel;

[0023] (2), the acylation reaction temperature is 70°C, and the acylation reaction time is 6 hours, and the crude product of tetrabutylurea is obtained;

[0024] (3) After the crude tetrabutylurea was left to stand for 30 minutes, the mother liquid water in the lower layer was separated, and the separated crude tetrabutylurea was distilled at a vacuum degree of -0.094MPa and a kettle temperature of 210°C to obtain the final product of tetrabutylurea .

Embodiment 3

[0026] (1), add di-n-butylamine, phosgene and 20% sodium hydroxide solution in a molar ratio of 2: 1.05: 2.1 in the reaction vessel;

[0027] (2), the acylation reaction temperature is 80°C, and the acylation reaction time is 8 hours, and the crude product of tetrabutylurea is obtained;

[0028] (3) After the crude tetrabutylurea was left to stand for 30 minutes, the mother liquid water in the lower layer was separated, and the separated crude tetrabutylurea was distilled at a vacuum degree of -0.096MPa and a kettle temperature of 220°C to obtain the final product of tetrabutylurea .

[0029] The detection results of three embodiments are as follows:

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com