Gate-type bucket wheel stacker-reclaimer

A bucket-wheel stacker-reclaimer and door-type technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of unsteady and safe lifting, inconvenient adjustment of the landing point, and low drop of the transfer point, so as to achieve the goal of adjusting the drop Easy to point, improve stability and safety, and have the effect of large space in the beam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

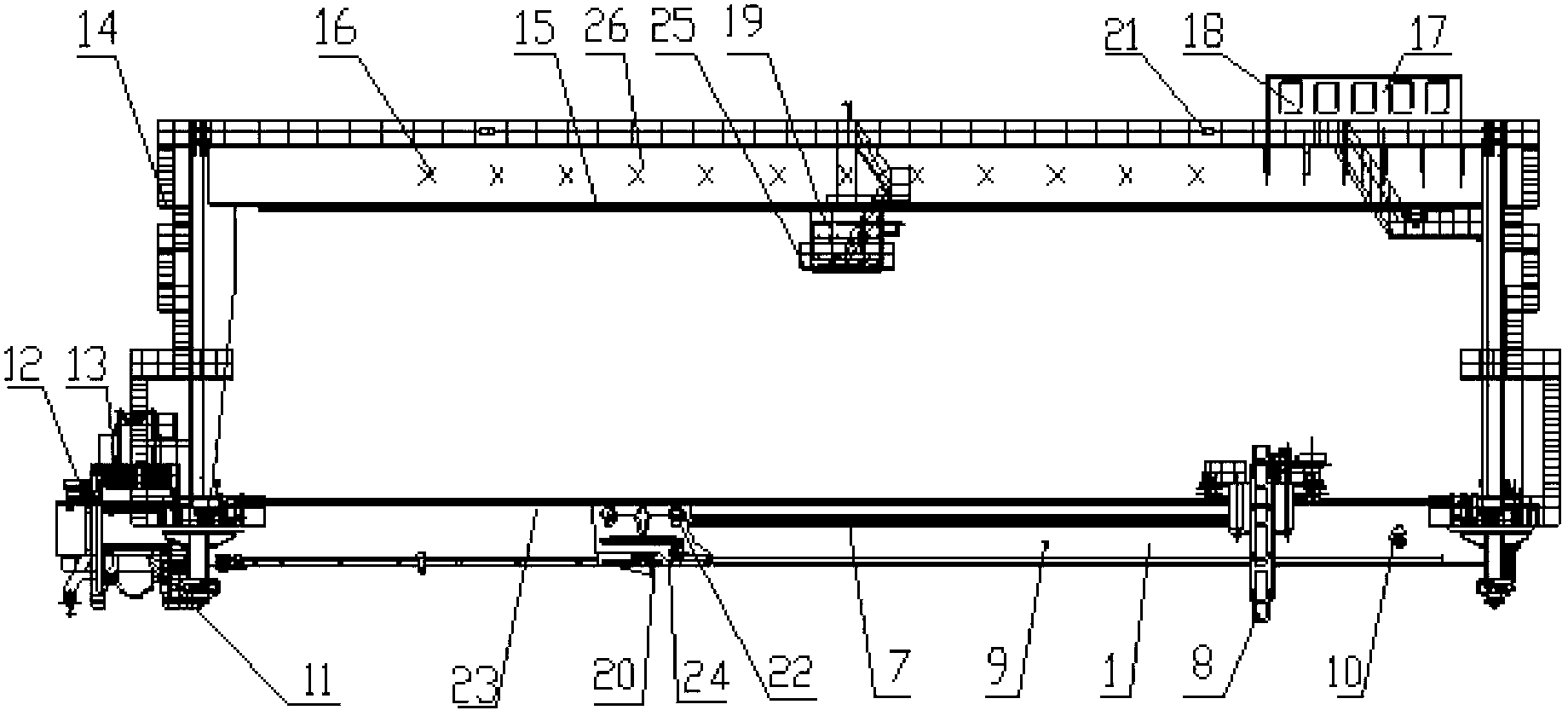

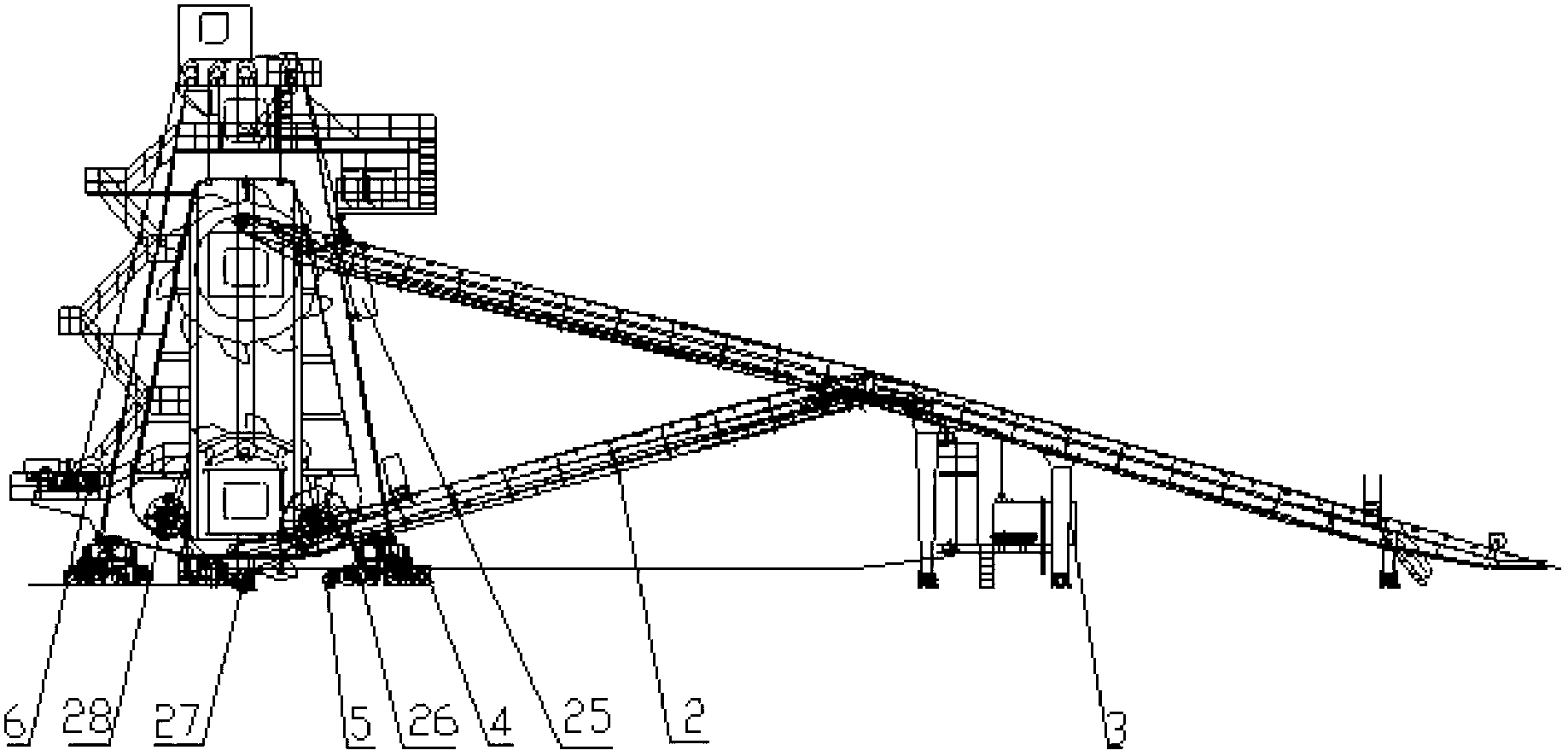

[0012] like figure 1 , 2 As shown, the gantry bucket wheel stacker and reclaimer includes movable beam 1, switchback tail car 2, dust removal system 3, cart traveling mechanism 4, cart traveling detection device 5, movable beam lifting mechanism 6, roller machine tow cable 7 , roller mechanism 8, limit device 9, moving tape machine tow cable 10, tail car retrieving and dropping hopper 11, stacking conversion mechanism 12, tail car stacking and dropping hopper 13, escalator walking platform 14, single girder crane 15, signage 16. Electric room 17, electrical system 18, driver's cab 19, material level detection device 20 and inventory system 21, movable beam 1 is equipped with reclaiming tape machine 22, stacking tape machine 23 and moving tape m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com