Storage drawer with coiled energy storage pushing trolley

A storage drawer and trolley technology, which is applied in the field of storage drawers, can solve the problems that the storage space needs to be further improved, the convenience needs to be further improved, and the storage drawer has no guiding groove, so as to avoid contact and increase stability , Facilitate the effect of pushing out warehouses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

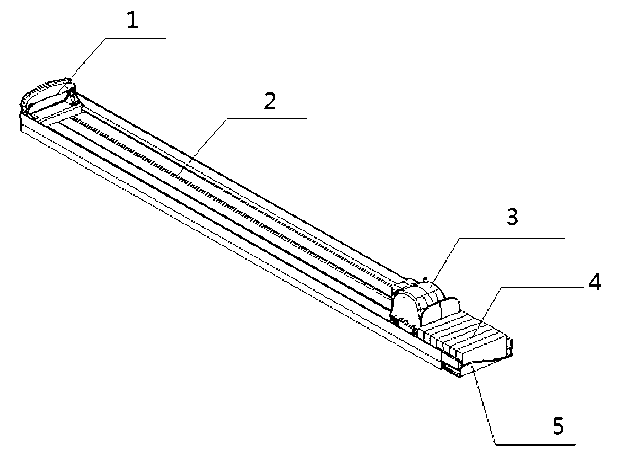

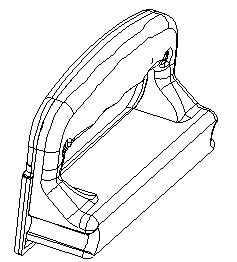

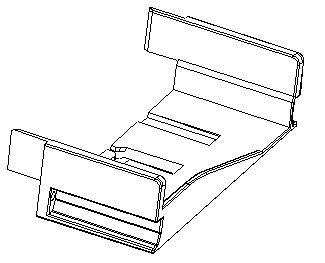

[0025] A storage drawer with a volute energy storage push trolley, comprising a handle 1, a drawer frame 2, a push trolley 3, and a bin outlet 5, wherein the rear end of the drawer frame 2 is provided with a handle 1, and the front end of the drawer frame 2 is provided with a bin outlet Port 5, the push trolley 3 is set on the drawer rack, and boxed items are placed between the push trolley and the exit 5;

[0026] The bottom plate of the drawer frame 2 is provided with three grooves, the three grooves are parallel to each other and parallel to the extension direction of the drawer frame, and the cross section of the middle groove is an inverted "T" shape; The traction line, the power mechanism can drive the winding mechanism to rotate, the winding mechanism is wound with a traction line, the other end of the traction line is fixedly connected to the outlet 5, two sets of rollers are set under the push trolley, and one set of rollers is located at the bottom of the push trolley...

Embodiment 2

[0031] A storage drawer with a volute energy storage push trolley, comprising a handle 1, a drawer frame 2, a push trolley 3, and a bin outlet 5, wherein the rear end of the drawer frame 2 is provided with a handle 1, and the front end of the drawer frame 2 is provided with a bin outlet Port 5, the push trolley 3 is set on the drawer rack, and boxed items are placed between the push trolley and the exit 5;

[0032]The bottom plate of the drawer frame 2 is provided with three grooves, the three grooves are parallel to each other and parallel to the extension direction of the drawer frame, and the cross section of the middle groove is an inverted "T" shape; The traction line, the power mechanism can drive the winding mechanism to rotate, the winding mechanism is wound with a traction line, the other end of the traction line is fixedly connected to the outlet 5, two sets of rollers are set under the push trolley, and one set of rollers is located at the bottom of the push trolley....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com