Powder body packing machine valve

A packaging machine and valve technology, applied in the direction of packaging, transportation and packaging, and the type of packaged items, can solve the problems of multi-maintenance time, shortened cylinder life, slow action speed, etc., and achieve obvious economic benefits, high powder delivery speed, and reputation The effect of increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

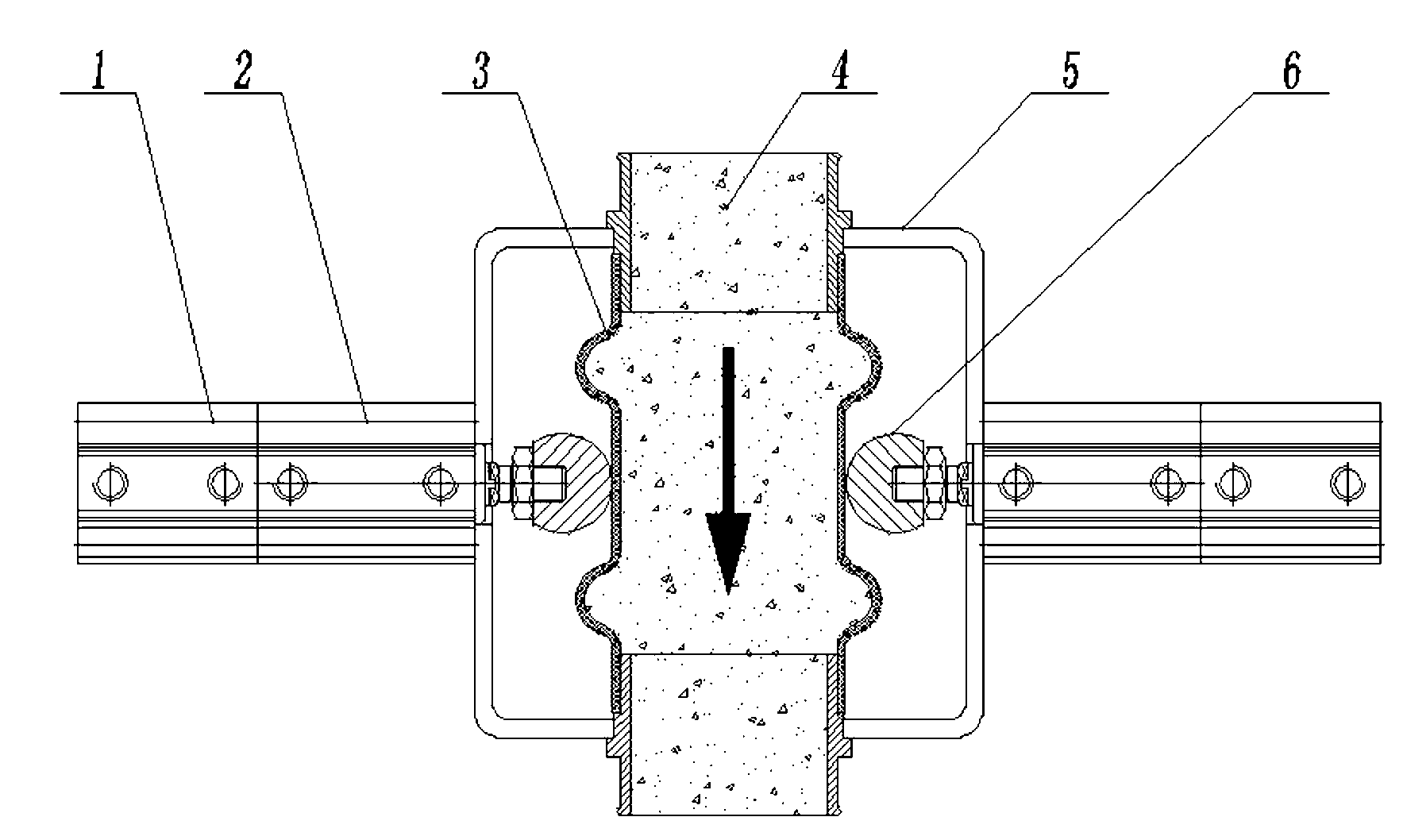

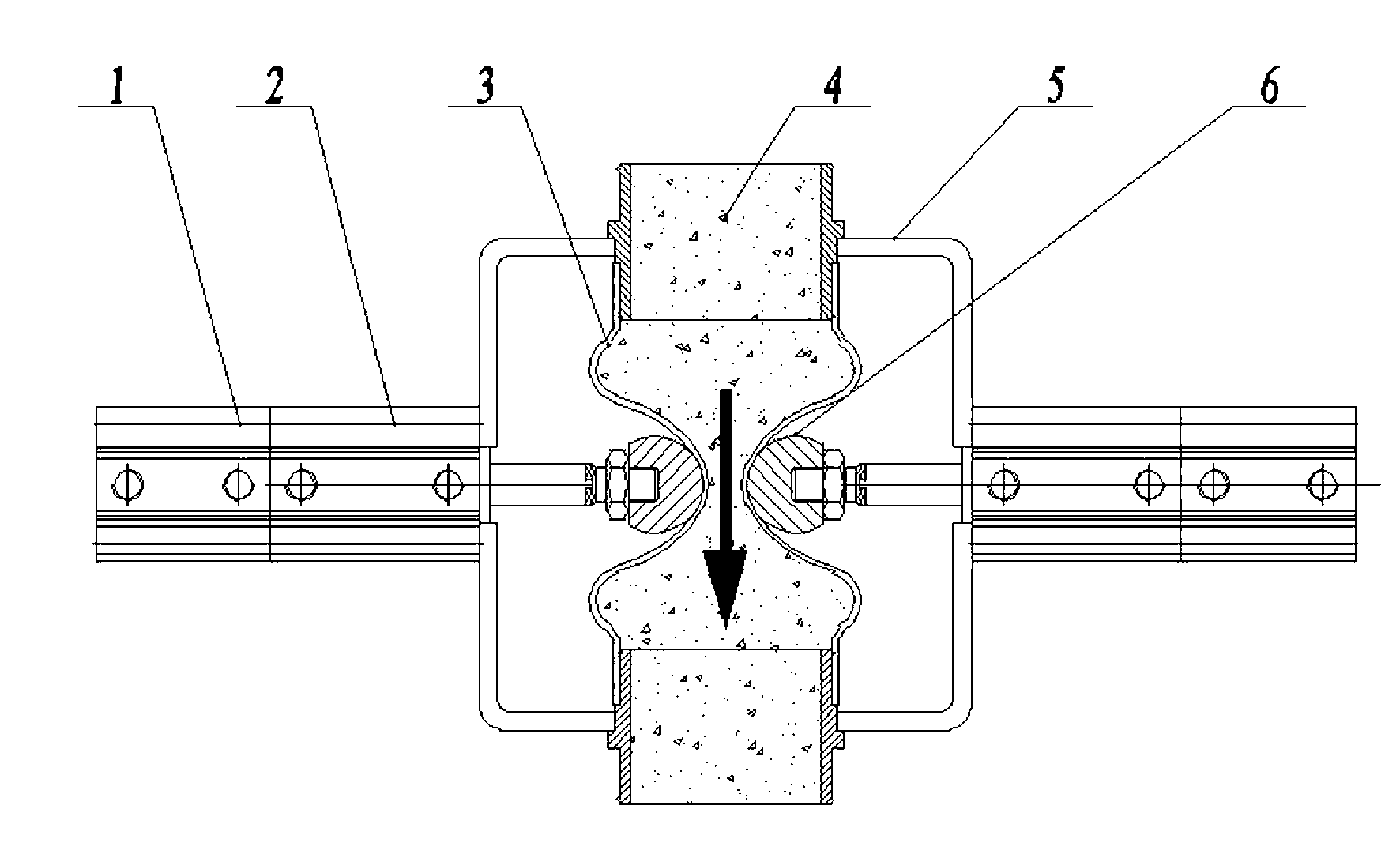

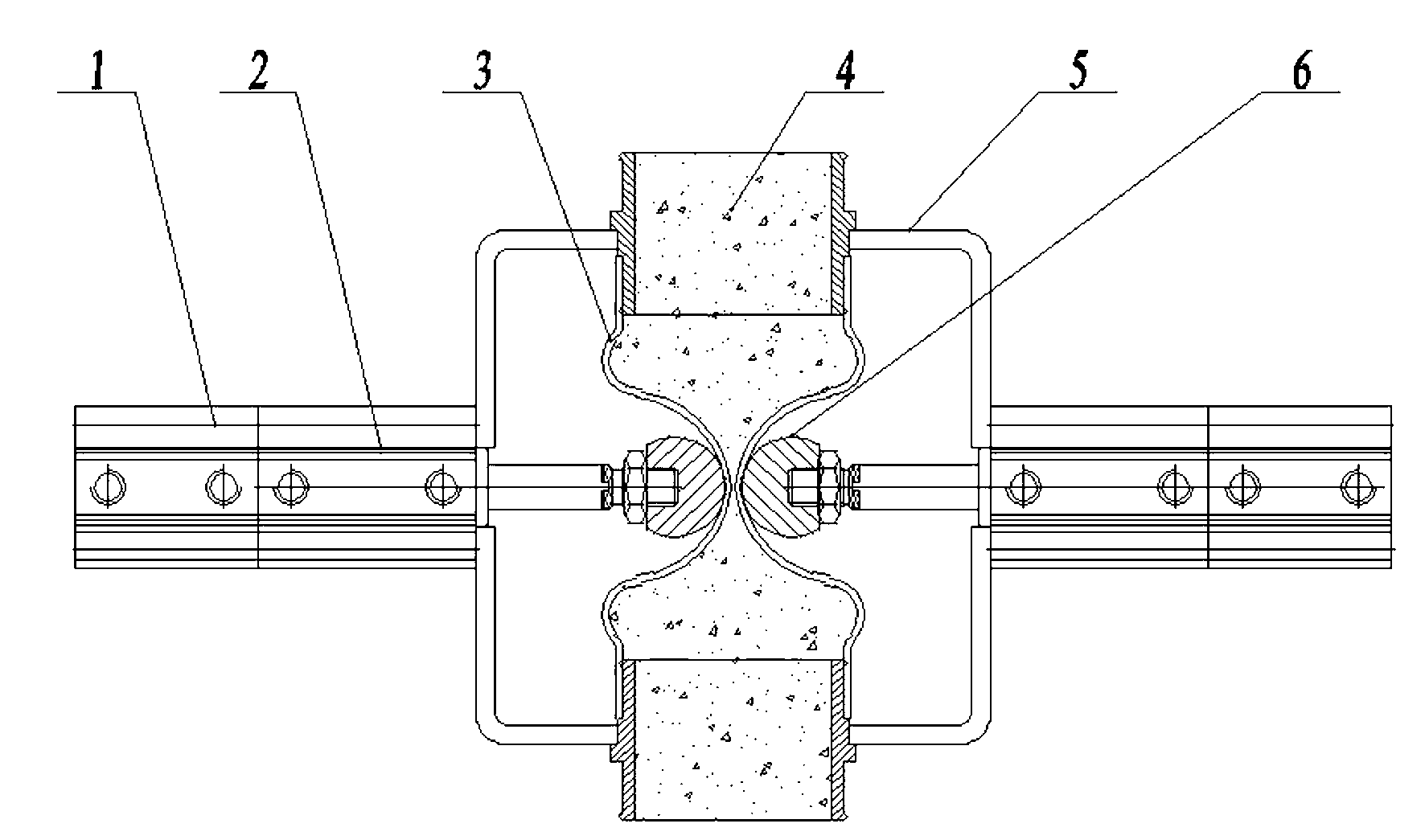

[0015] This example is a powder packaging machine valve with a fixed valve structure, including a front cylinder 1, a rear cylinder 2, a rubber hose 3, a valve frame 5, and a rubber hose clamping rod 6. The front-stage cylinder 1 is connected with the rear-stage cylinder 2 to form a double-stage cylinder. Two identical double-stage cylinders are arranged on the left and right sides of the valve frame 5 respectively. The end pipe joints are respectively fixed on the upper end and the lower end of the valve frame 5 . The left and right sides of the valve frame 5 are double-stage cylinders composed of the front cylinder 1 and the rear cylinder 2. The rubber hose clamp rod 6 is connected to the rubber hose clamp rod 6 through the piston rod. The rubber hose clamp rod 6 moves left and right under the drive of the cylinder, so that the cross-sectional area of the rubber hose 3 It becomes larger or smaller, and the valve is opened or closed at the same time, forming a fixed valve s...

Embodiment 2

[0017] This example is a powder packaging machine valve with an adjustable valve structure. Embodiment 2 is basically the same as Embodiment 1. The difference is that one side of the valve frame 5 is provided with a front cylinder 1 and a rear cylinder 2. The double-stage cylinder has an adjustable stroke cylinder 7 on the other side to form an adjustable valve structure.

[0018] working principle

[0019] When the packaging starts, the cylinder 2 drives the rubber hose clamp rod 6 to run outwards to the end, the valves are fully opened, the rubber hose 3 has the largest cross-sectional area, and a relatively high conveying speed can be obtained, such as figure 1 shown;

[0020] When the packaging weight is close to the target weight value, the cylinder 1 drives the clamp rod to move inward, so that the valve is closed and the cross-sectional area of the rubber hose 3 becomes smaller, which greatly limits the conveying speed of the powder material 4 in the rubber hose, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com