Micro-seal ring ferrule module

A sealing ring and snare technology, used in metal processing, metal processing equipment, manufacturing tools, etc., to achieve a wide range of applications, ingenious structure, and meet the effect of assembly rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

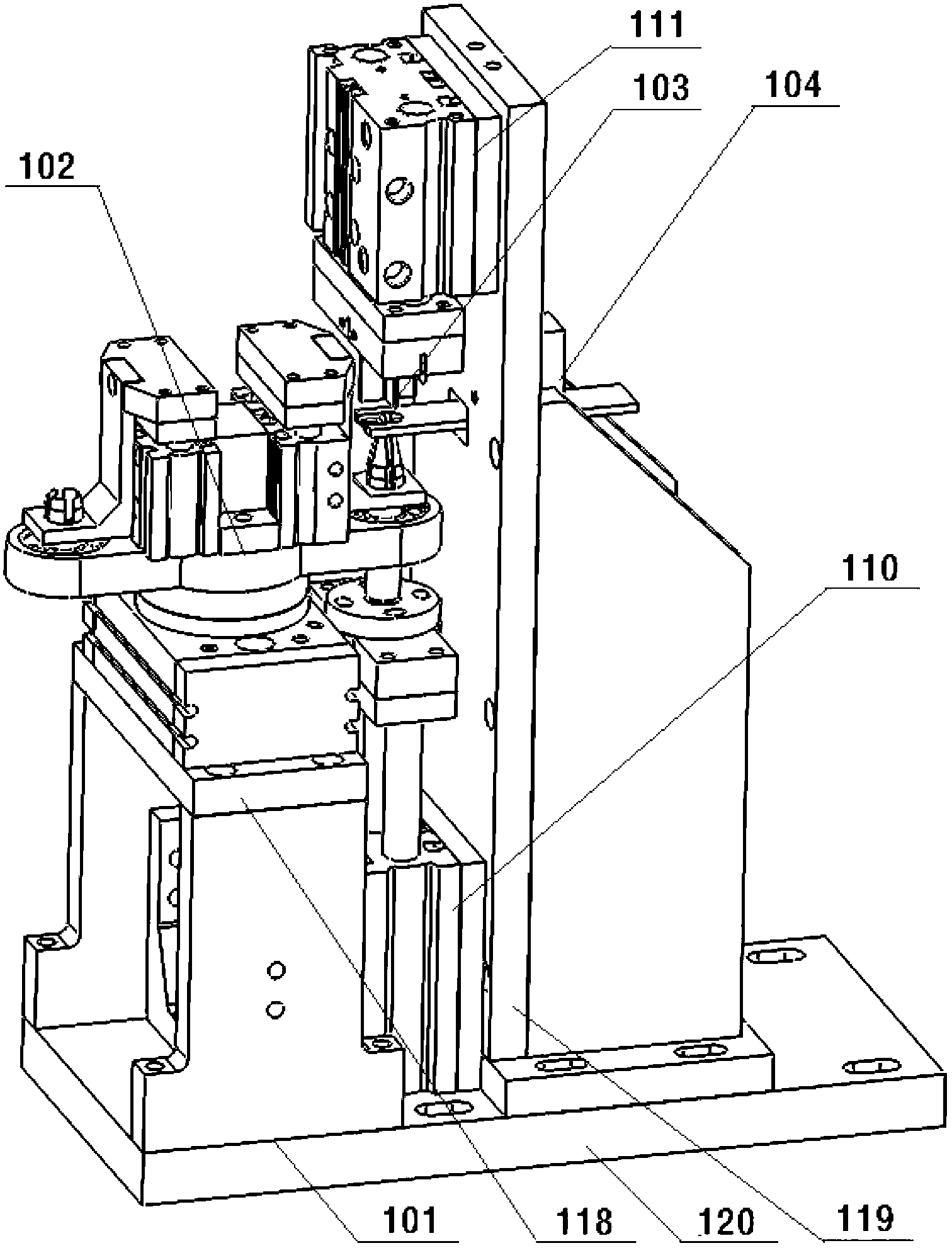

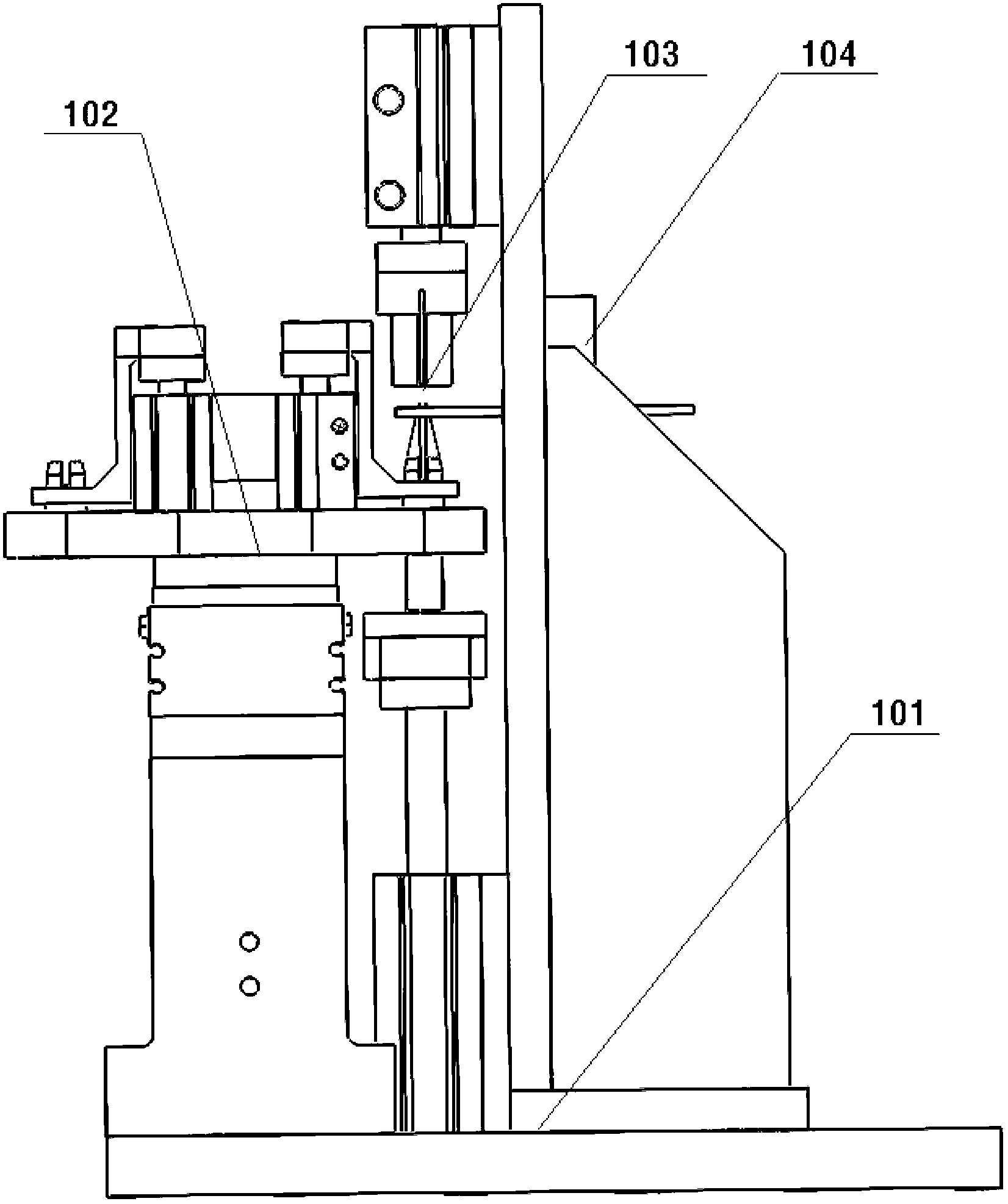

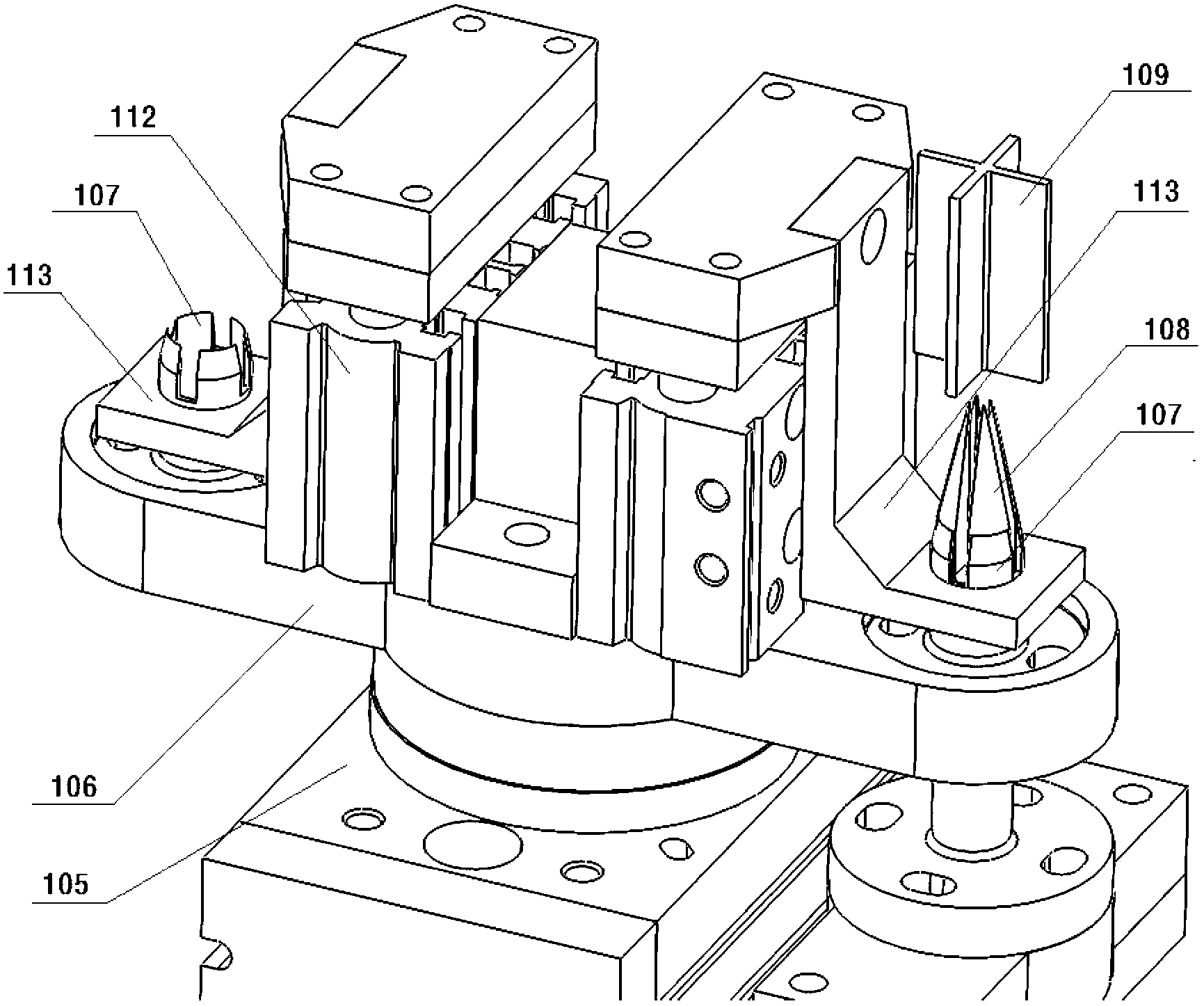

[0021] refer to Figure 1 ~ Figure 4 , a miniature sealing ring ferrule module, which is used in the process of assembling the sealing ring of a valve stem part of a valve core flexible automatic assembly machine. Of course, the miniature sealing ring ferrule module can also be applied to other automatic assembly machines or a separate sealing ring assembly in the device. A miniature sealing ring ferrule module, comprising an assembled support 101, a swing plate structure 102, a miniature seal ring ferrule structure 103 and a miniature seal ring feeding structure 104, the swing plate structure includes a swing plate cylinder 105, a swing plate 106, a support Ring sleeve 107, the swing plate cylinder 105 is fixed on the swing plate cylinder bracket 118 of the assembled bracket 101, the swing plate 106 is installed on the swing plate cylinder 105, and the support ring s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com