Negative-pressure control valve and negative-pressure drainage bottle

A negative pressure control valve and negative pressure drainage technology, which is applied to wound drainage devices, valves, suction devices, etc., can solve problems such as easy reflux and limited negative pressure in drainage bottles, and achieve accelerated wound healing, reliable time, and reliable sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

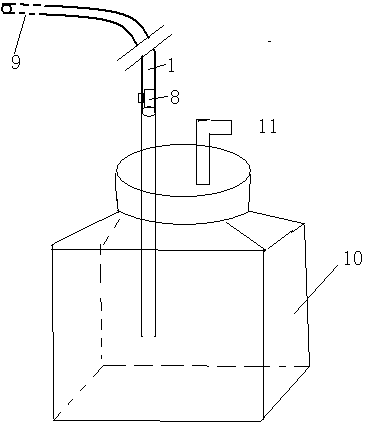

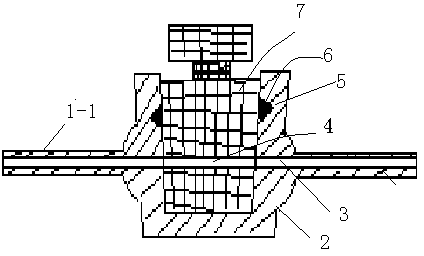

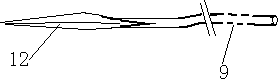

[0021] With reference to the accompanying drawings, the drainage tube 1, the conduit 1-1 of the valve seat, the valve seat 2, the valve seat guide hole 3, the valve core guide hole 4, the valve core convex ring 5, the valve seat groove 6, and the valve core 7. Valve 8, drainage tube end 9, drainage bottle 10, drainage bottle outer tube 11, puncture needle 12, connecting tube 13, fastening leather ring 14. The valve includes a valve seat 2 and a valve core 7. The valve seat is provided with a valve seat guide hole 3 and a valve seat groove 6. The valve core is provided with a valve core guide hole 4, a valve core convex ring 5, and a conduit 1 (drainage tube) Connected with the guide hole 3 of the valve seat, the drainage tube end 9 is used for drainage of the wound, and the valve core of the tube valve rotates in the valve seat to adjust the drainage, adjust the flow rate of the drainage tube connected to the drainage bottle, and also be used to control the flow of the drainage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com