Heating vinyl house and heating film for heating vinyl house

A plastic greenhouse and heating film technology, applied in the field of plastic film, can solve problems such as unsatisfactory, complicated construction, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

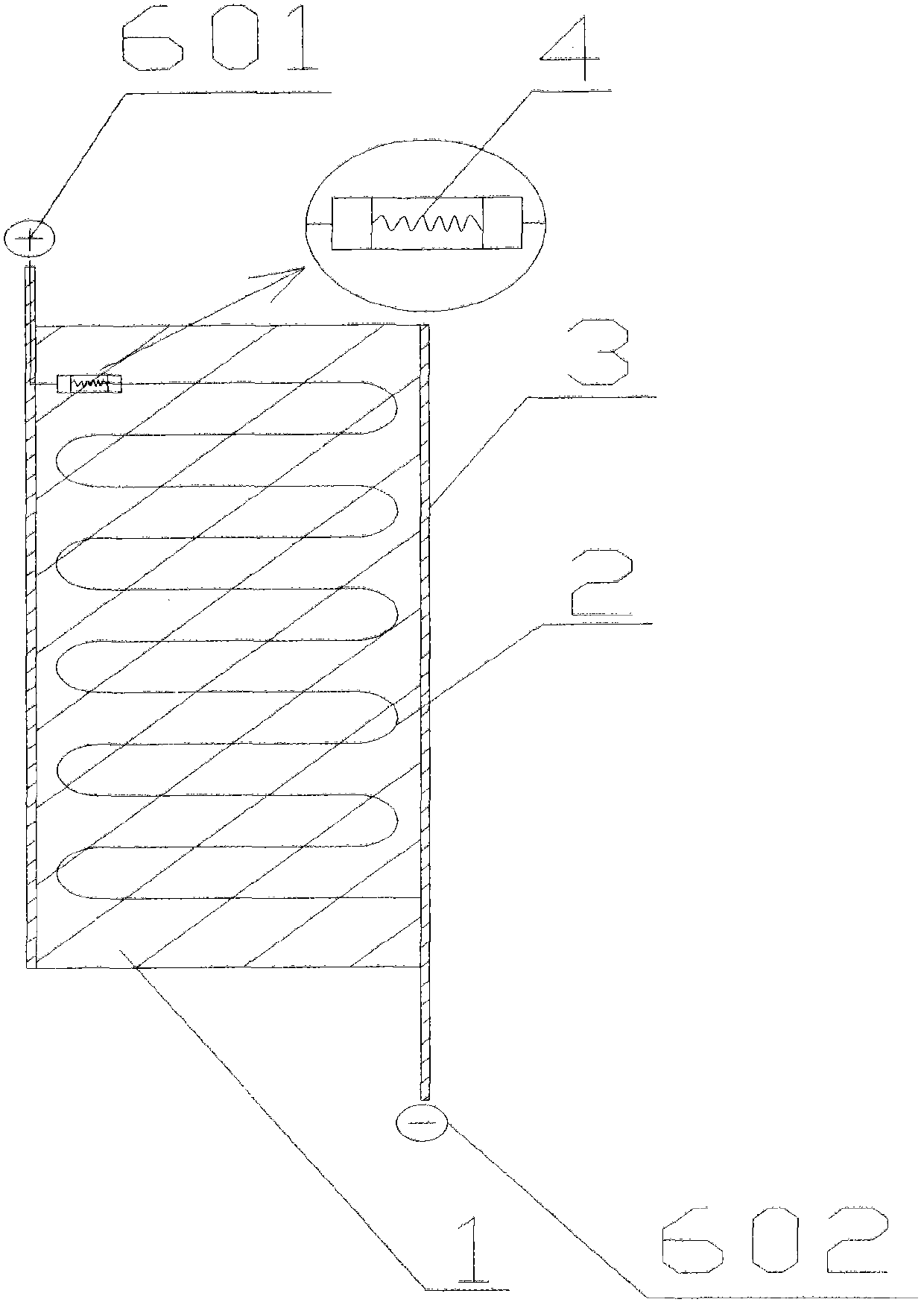

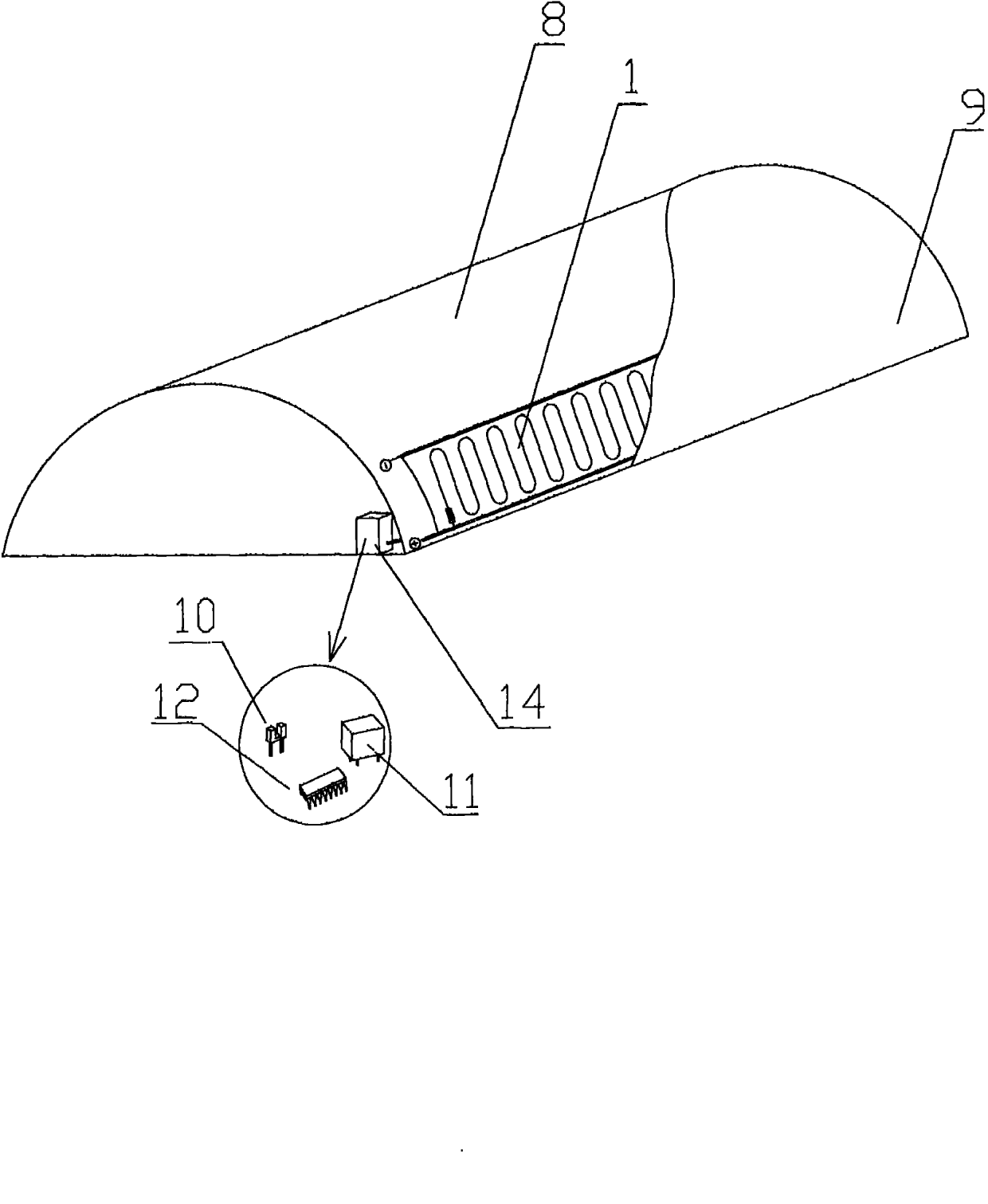

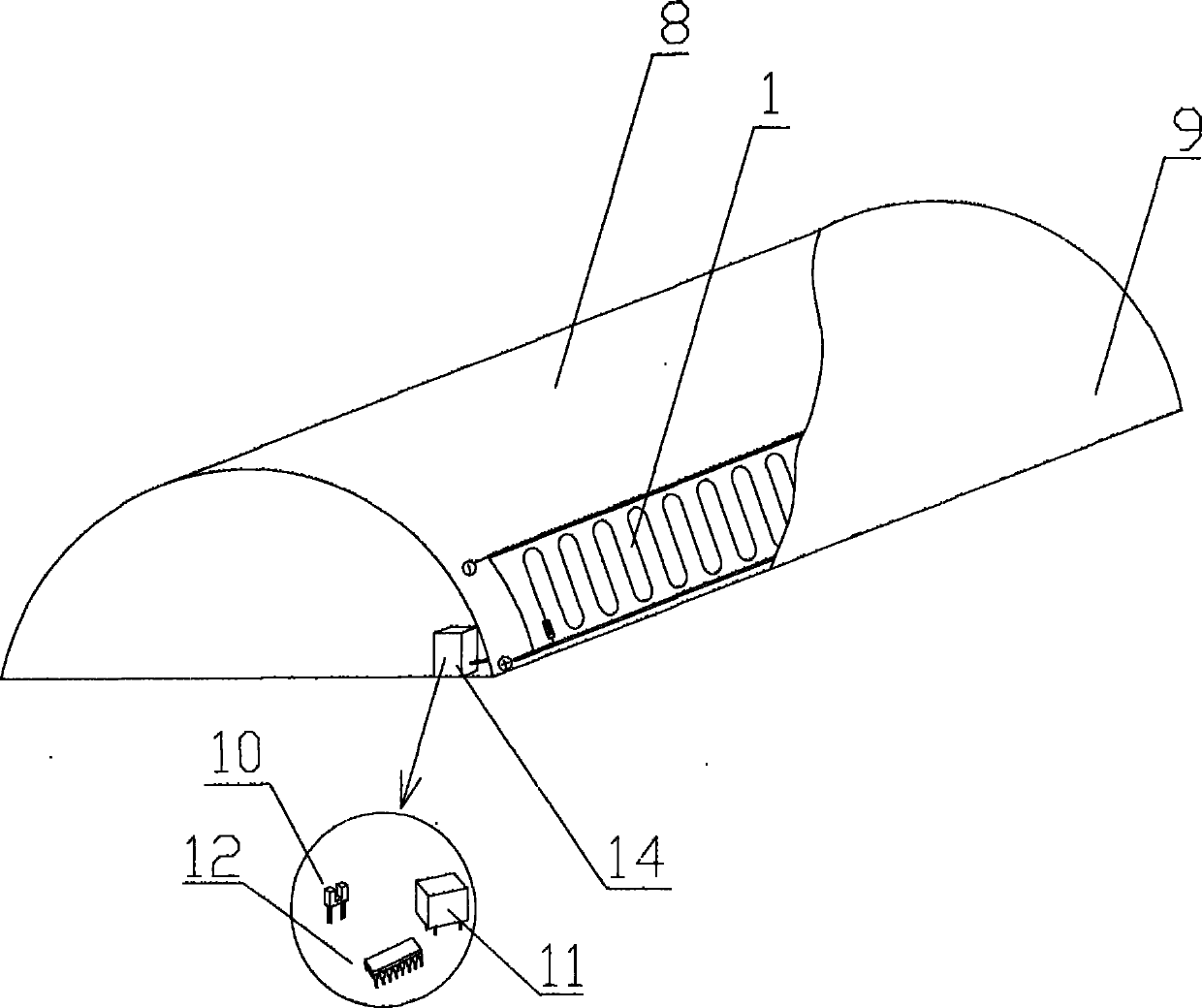

[0013] like figure 1 As shown, on the heating film body 1, PE or PVC heating wire 2 is coiled in an "S" shape, and the longitudinal sides of the heating film body 1 are respectively conductive steel cables 3. The positive pole 601 of the power supply and the negative pole 602 of the power supply are respectively connected to the PE or PVC heating wire 2. The heating film is obtained by adding the heating wire 2 into the middle of two upper and lower ordinary plastic films. As shown in the partial cross-sectional view of the arrow: the outer layer of the conductive steel cable 3 is wrapped with a conductive metal braid 5 for conducting electricity, and the center of the steel cable is a steel wire 7 for reinforcement and resistance to pulling. Set with insurance. Compared with the prior art, the heat-generating film can directly replace one or two sidewall films of the plastic greenhouse due to its light transmittance, and can realize artificial electrification without affect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com