Substrate for light-emitting element, manufacturing method thereof, and light-emitting device

A light-emitting element and manufacturing method technology, applied in the direction of electrical components, electric solid-state devices, semiconductor devices, etc., can solve the problems of increasing the overall size, difficulty in coping with the miniaturization of LED products, etc., and achieve the effect of improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Hereinafter, the light-emitting element substrate of the present invention and its manufacturing method will be described in detail. In addition, the light-emitting device of the present invention will be described along with this description. In addition, various elements shown in the drawings are only schematically shown for understanding of the present invention, and the size ratio, appearance, and the like may be different from the actual products.

[0071] [Substrate for light-emitting element of the present invention]

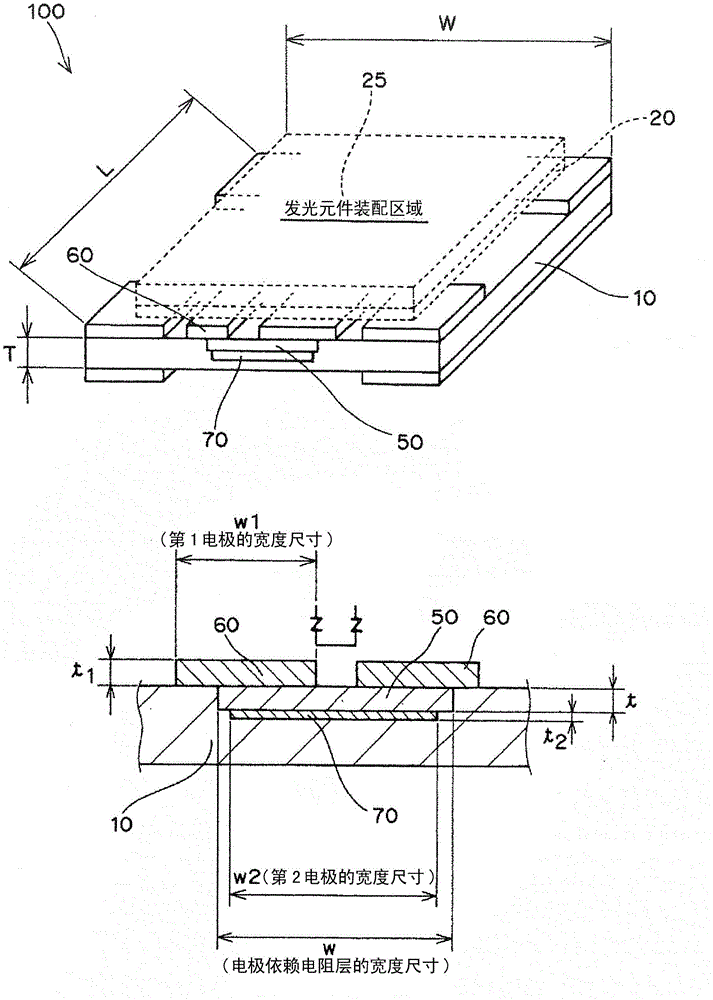

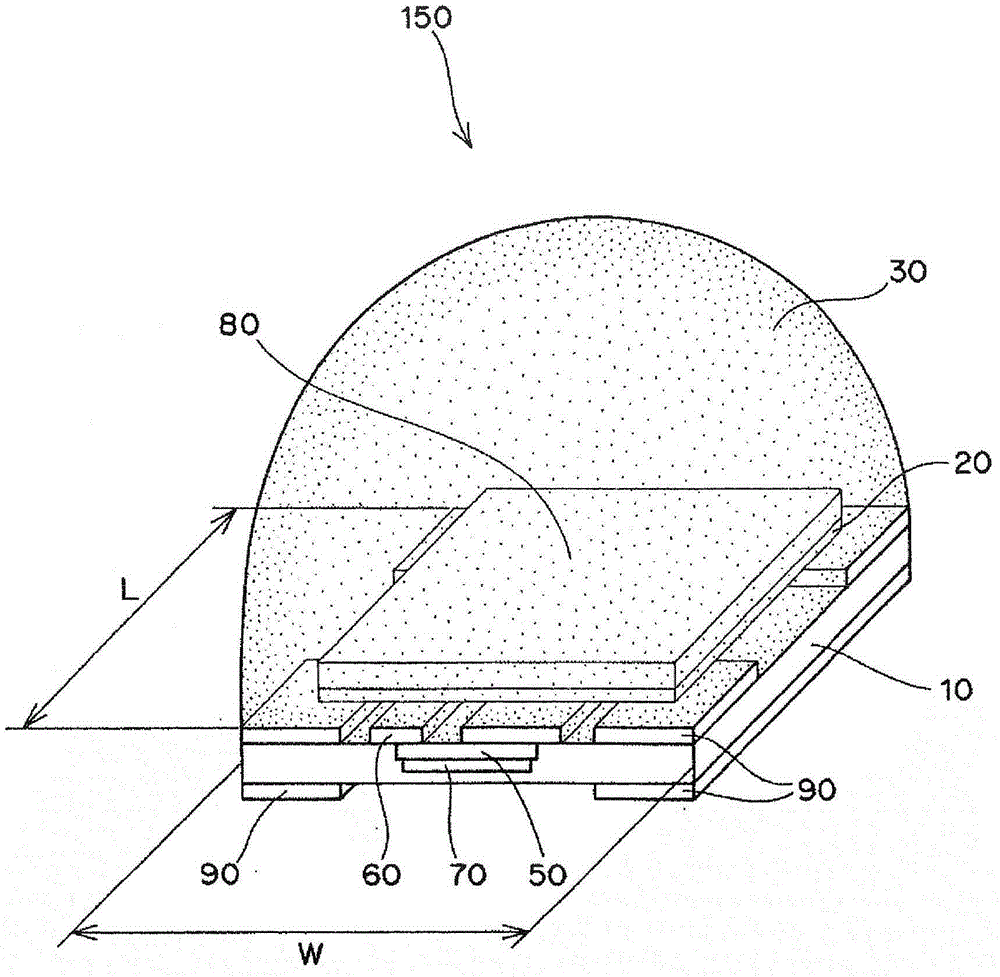

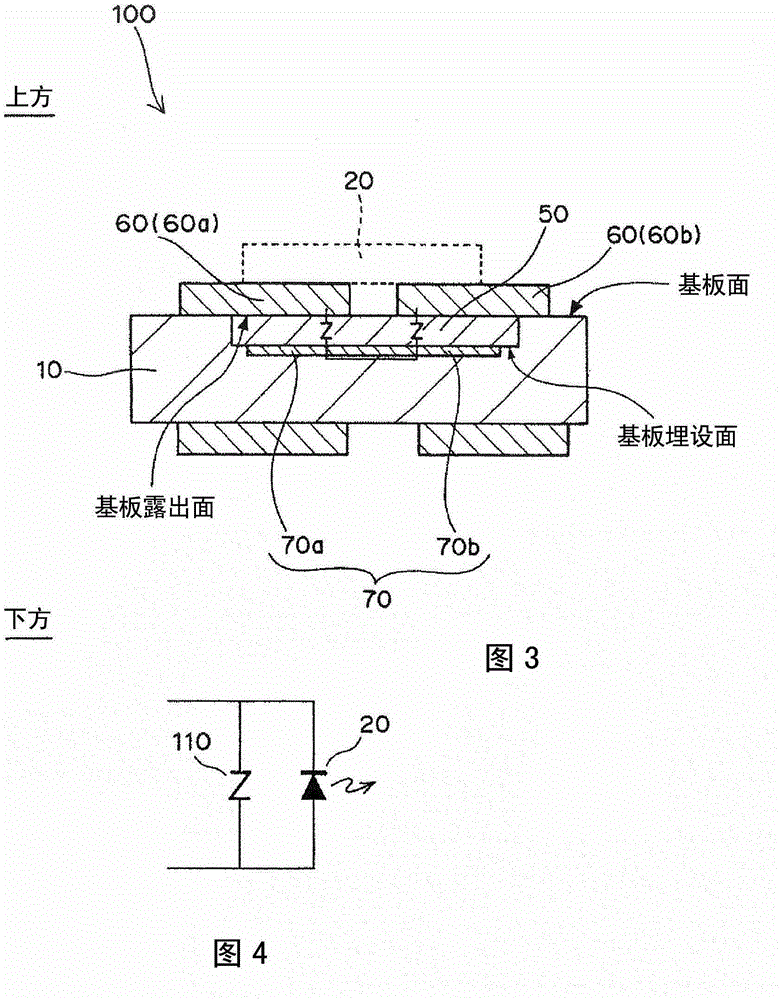

[0072] In the substrate for a light-emitting element of the present invention, a voltage-dependent resistance layer as a protective element is embedded in the substrate area overlapping the mounted light-emitting element. That is, as figure 1 As shown, in the light-emitting element substrate 100 of the present invention, a voltage-dependent resistance layer 50 as a protective element is buried in the light-emitting element mounting area 25 thereof. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com