Light interference gas detection device and working condition detection method thereof

A gas detection and optical interference technology, which is applied in the measurement of phase influence characteristics, etc., can solve problems such as scientific judgment of working conditions, and achieve the effect of improving safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will be described in detail below. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

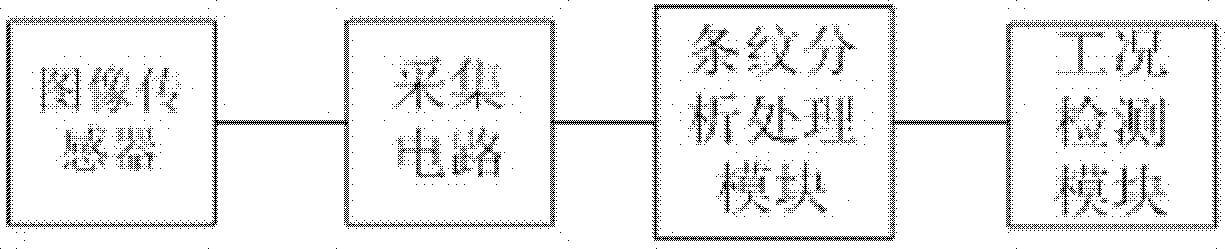

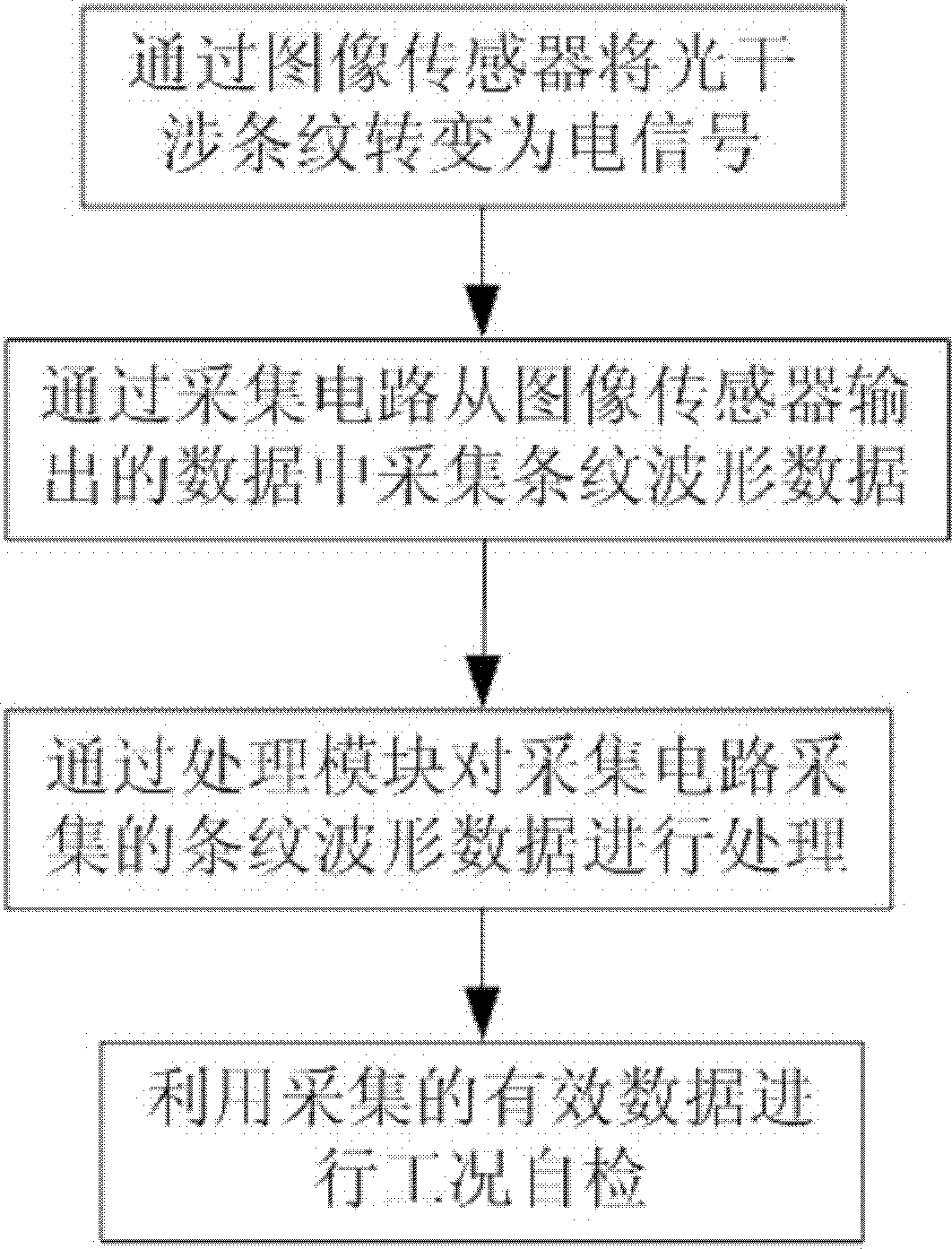

[0027] see figure 1 , an optical interference gas detection device, including a light source, an optical path and a gas path, and an image sensor, where optical interference fringes are converted into electrical signals, preferably an area array image sensor;

[0028] The acquisition circuit collects the fringe waveform data from the data output by the image sensor;

[0029] The fringe analysis and processing module analyzes and processes the fringe waveform data collected by the acquisition circuit, and extracts valid data therefrom;

[0030] The working condition detection module evaluates the working condition according to the analysis and processing results of the fringe waveform data. The working condition dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com