Device and method for detecting position degree of valve guide pipe holes of cylinder cover of engine

An engine cylinder head and valve guide technology, which is applied to mechanical measuring devices, measuring devices, and mechanical devices, etc., can solve the problem of not being able to ensure that the cumulative error of multiple guide holes can meet the precise position of the installed valve guide rod and the large deviation of the guide hole position. , the poor sealing performance of the guide rod valve, etc., to achieve the effect of simple structure, convenient operation and reducing cumulative error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

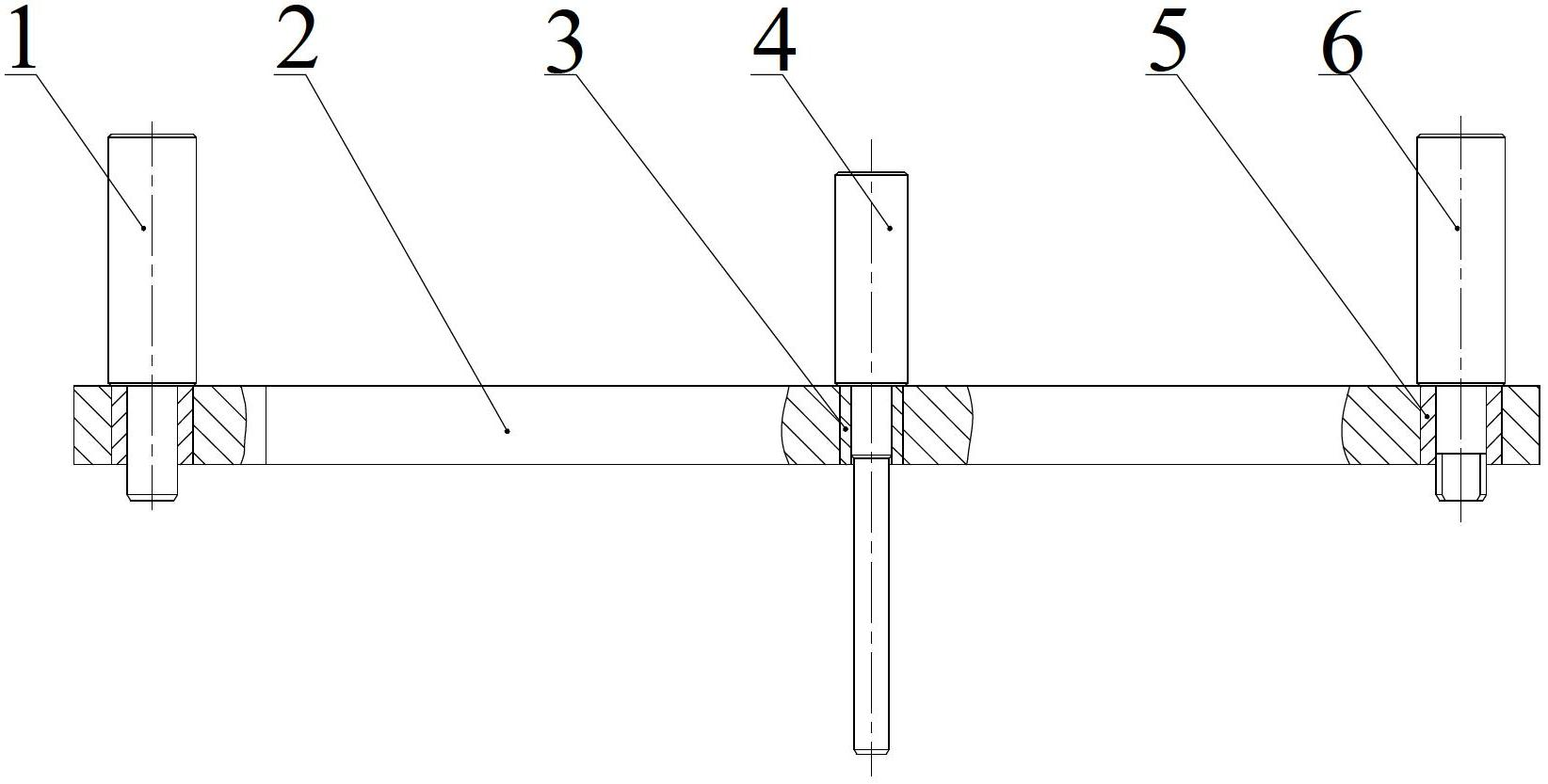

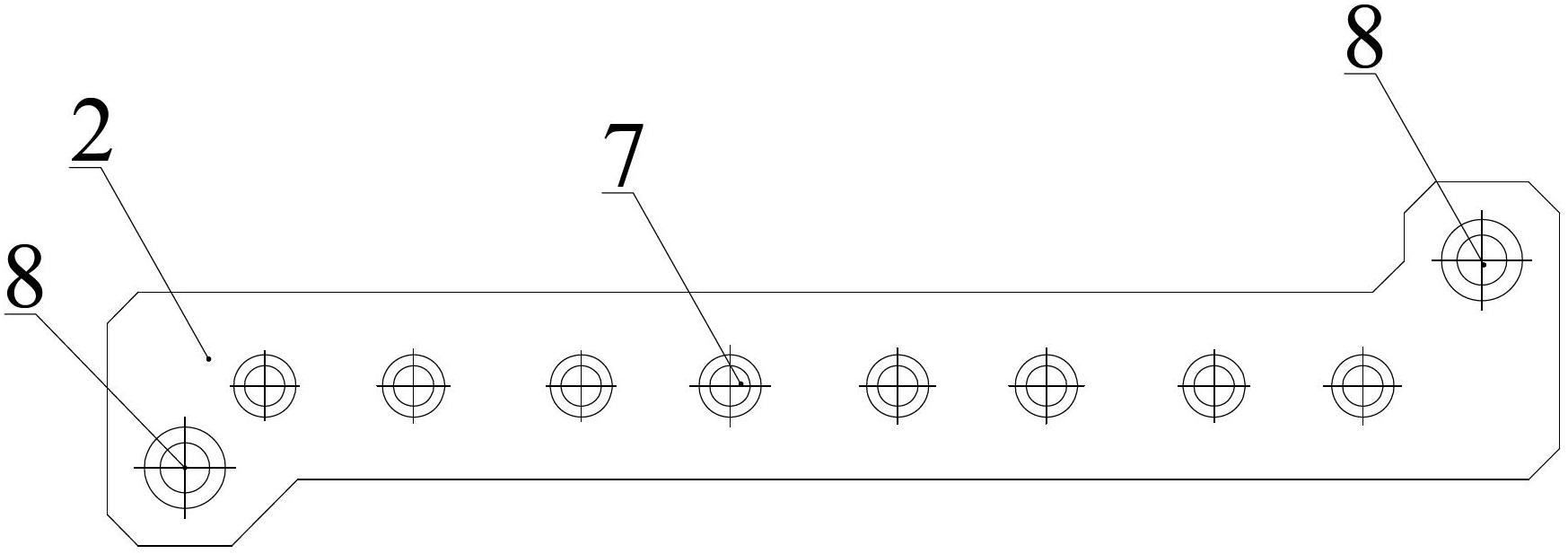

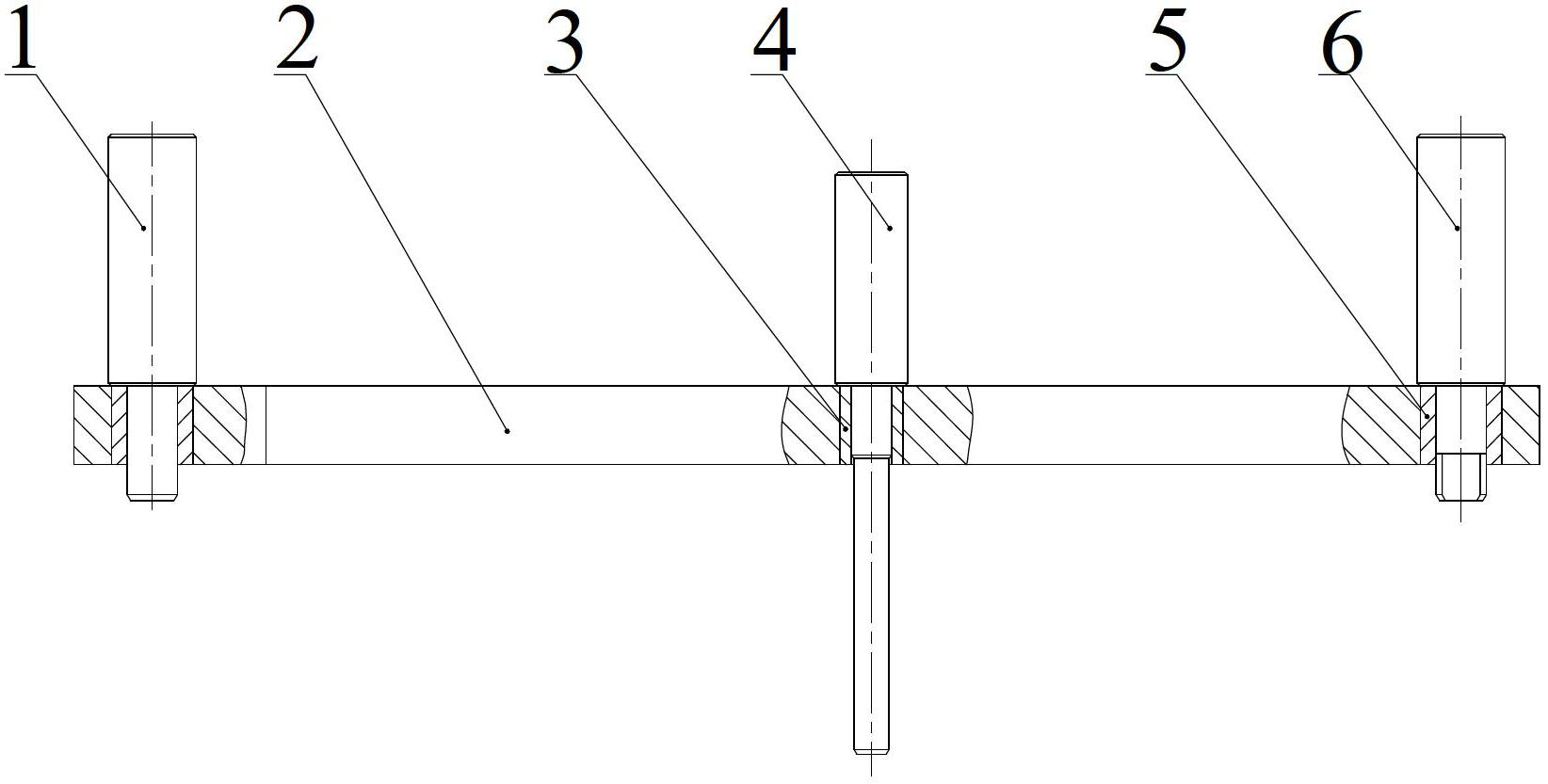

[0014] The invention relates to an engine cylinder head valve guide hole position detection device, which includes a special detection mandrel 4 which is the same as that used in the prior art. In order to solve the problems existing in the prior art, such as figure 1 and figure 2 As shown, the detection device also includes a detection template 2, the detection template 2 is a long plate shape, and the detection template 2 is provided with the same number and position alignment as the valve guide holes on the cylinder head for the insertion of the detection mandrel 4. For the detection hole 7, during detection, the detection template 2 is positioned on the bottom surface of the cylinder head by a positioning mechanism. During detection, the cylinder head is placed upside down on the detection platform, and the bottom surface of the cylinder head is set upward. Compared with the prior art, the detection device is simple in structure and easy to operate. It only needs to inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com