Multi-bit drill corrector

A multi-head drill and corrector technology, which is applied to earth movers/excavators, construction, etc., can solve problems such as necking and irregular shape of groove sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

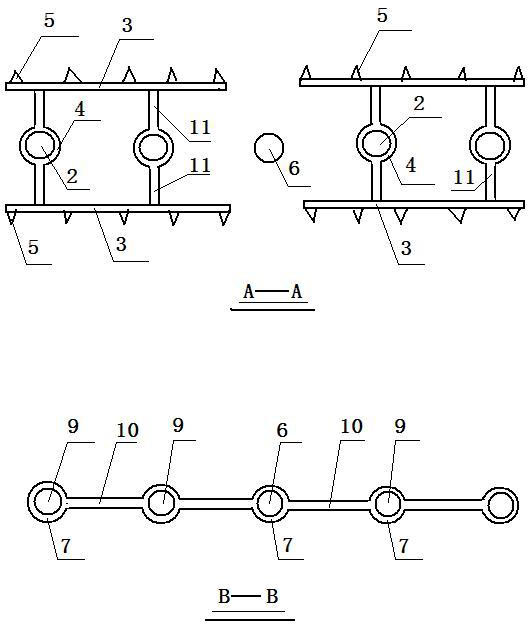

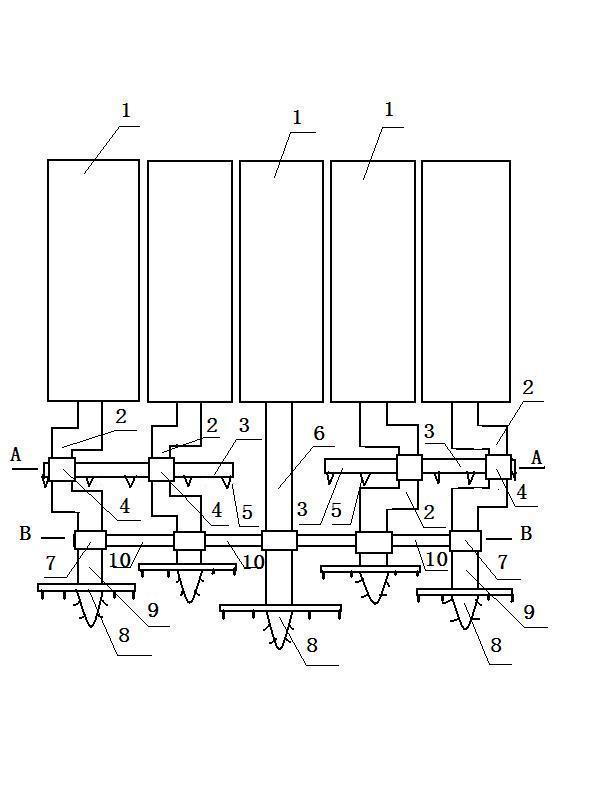

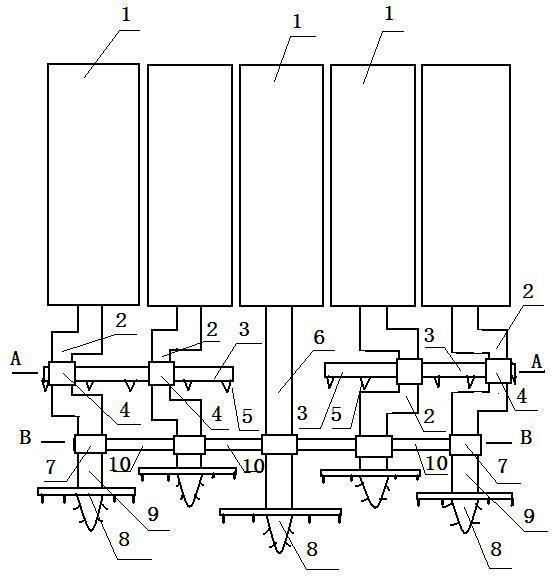

[0012] Accompanying drawing is a kind of concrete embodiment of the present invention, and this embodiment comprises five motors 1 that the upper end of multi-head drill is arranged side by side, and middle motor lower end is provided with drilling rod A6, and drill rod A lower end is provided with drill bit 8, and the lower ends of four motors on both sides are respectively A crankshaft 2 is provided, and the lower end of the crankshaft is connected to the drill bit 8 through the drill pipe B9. Both the drill pipe A and the drill pipe B are provided with sliding sleeves B, and each sliding sleeve B is connected through the connecting rod A10. The special features are: four There are sliding sleeves A4 on the crankshaft, the two sliding sleeves A on the left are connected to the two tool bars 3 on the left through the left connecting rod B11, and the two sliding sleeves A on the right are connected to the two right tool bars through the right connecting rod B11 3, the cutter ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com