Reinforcement construction method with soft foundation grouting in railway frame bridge jacking process

A construction method and grouting reinforcement technology, which is applied in basic structure engineering, soil protection, construction, etc., can solve the problems of long construction period, difficult operation, slow construction speed of oblique grouting method, etc., and achieve fast speed and normal operation Less interference and shorter construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

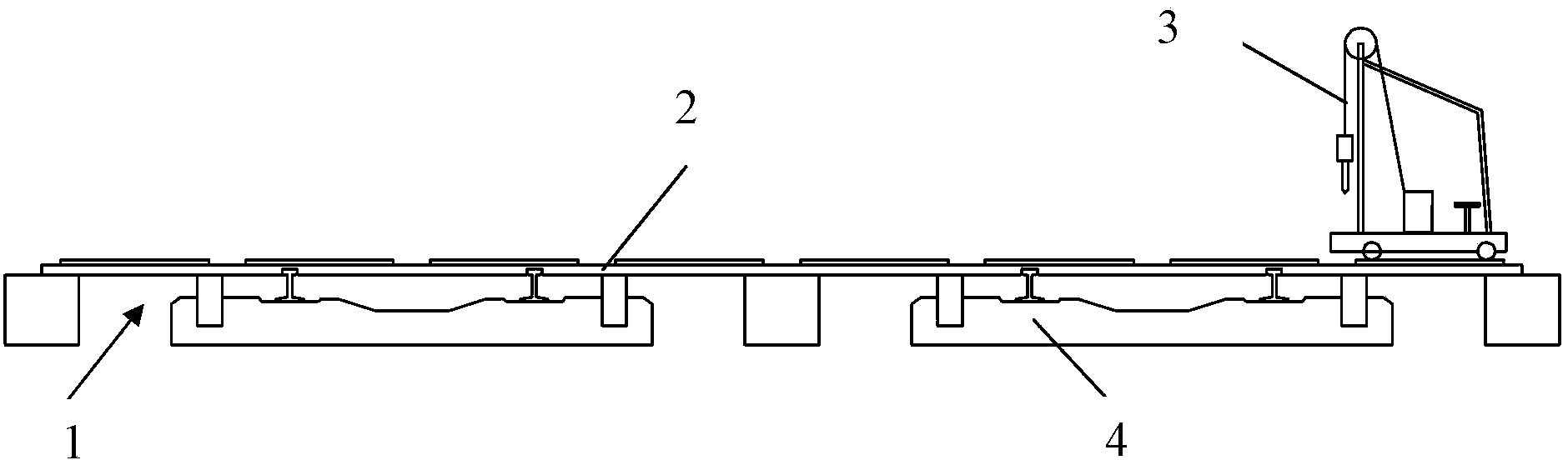

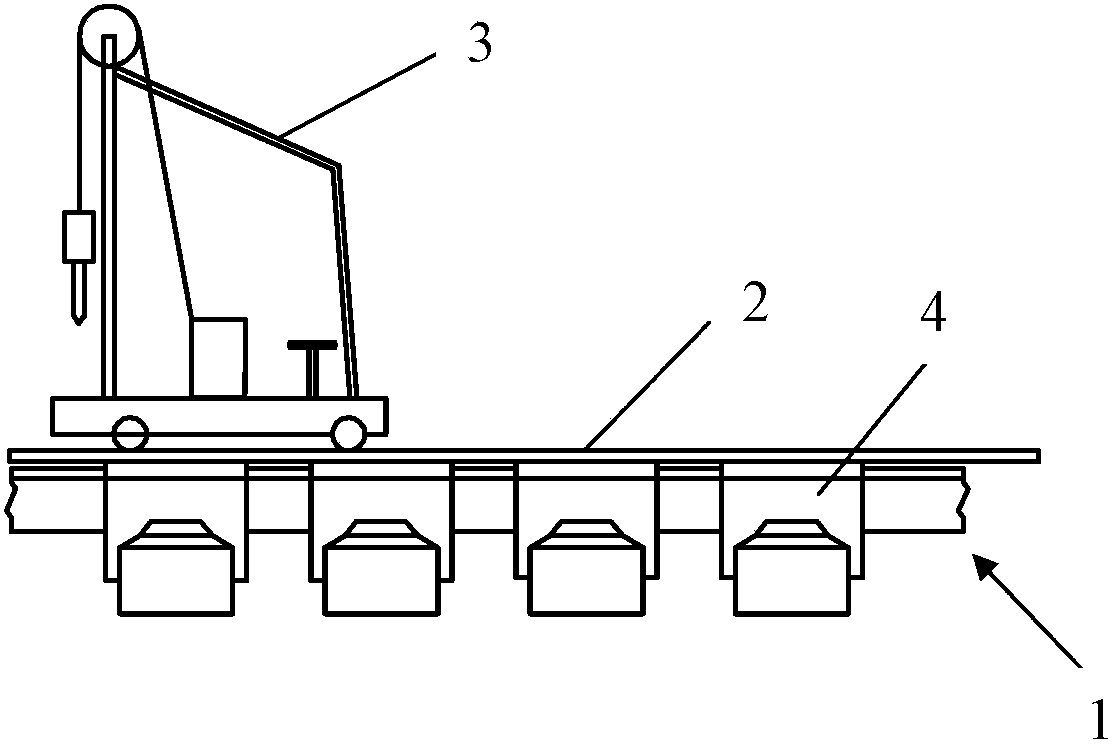

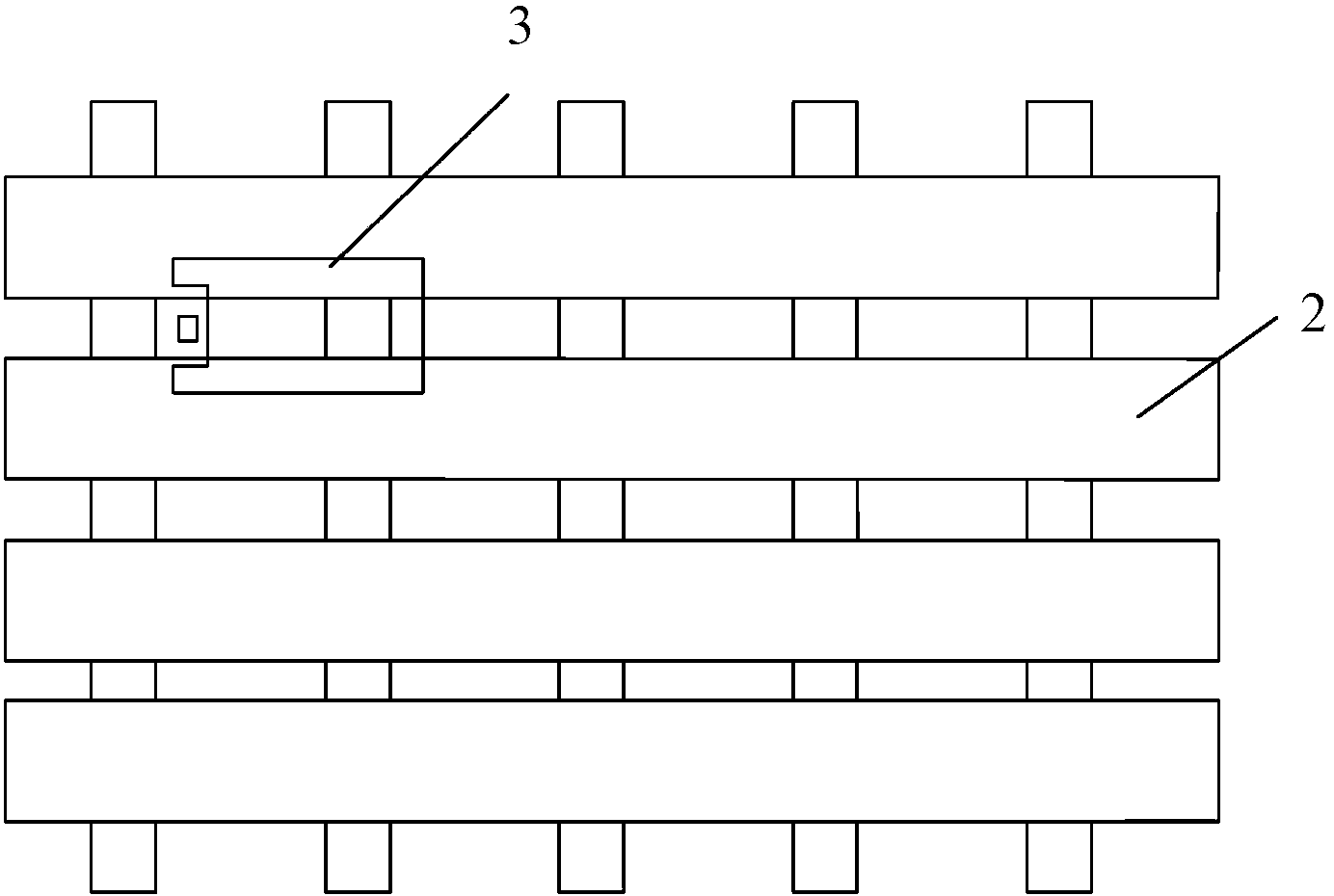

[0019] The grouting reinforcement construction method for the soft ground during the jacking process of the railway frame bridge provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] Such as figure 1 As shown, the soft ground grouting reinforcement construction method in the railway frame bridge jacking process provided by the invention comprises the following steps:

[0021] 1) Reinforce the soft soil foundation under the stock road on both sides of the frame bridge to be jacked in the station by oblique grouting method;

[0022] 2) Temporarily close any branch line on the side of the trunk line in the middle of the station, and then use oblique grouting from the branch line to reinforce the soft soil foundation below the trunk line ;

[0023] 3) Reinforce the soft soil foundation under the branch line 1 located in the middle of the station by using the vertical grouting method, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com