Electric equipment moisture resistance, corrosion resistance and insulation protection agent and preparation method thereof

A technology for insulation protection and electrical equipment, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of undiscovered patent documents, affect the life of electrical equipment, poor cleaning effect, etc., achieve strong dehydration effect, easy acquisition, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The raw materials of the embodiments of the present invention are all commercially available raw materials.

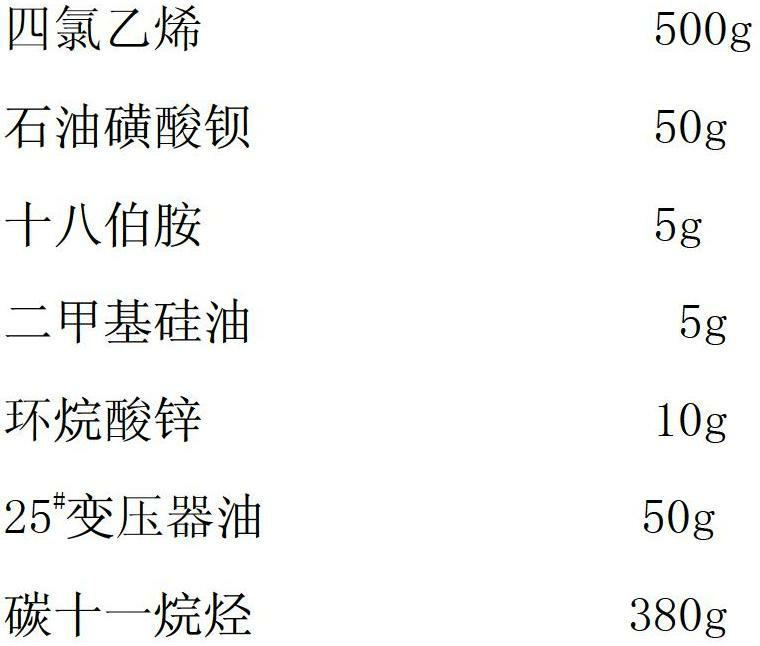

[0029] A moisture-proof and anti-corrosion insulating protective agent for electrical equipment, the composition of which is (take 1000g product as an example):

[0030]

[0031]

[0032] The steps of a preparation method of a moisture-proof and anti-corrosion insulating protective agent for electrical equipment are as follows:

[0033] ⑴ Will 25 # Transformer oil, barium petroleum sulfonate, and hexadecane ammonium are added into a container according to the weight ratio, heated to 80°C, and melted to form a mixture for later use.

[0034] ⑵Add carbon dedecane and tetrachlorethylene which have been left to stand and filter in the reaction kettle, then add zinc naphthenate and dimethyl silicone oil in turn under stirring conditions; then add dissolved barium petroleum sulfonate and cetyl primary amine and 25# transformer oil mixture, continue to stir for...

Embodiment 2

[0036] The composition of a moisture-proof and anti-corrosion insulating protective agent for electrical equipment is as follows (take 1000g finished product as an example):

[0037]

[0038] The steps of its preparation method are the same as in Example 1. Take 300g of the above solution and add 100g of propane butane to fill an aerosol product with a capacity of 458ml.

[0039] Mechanism of action of the present invention: clean electrical equipment through hydrocarbon solvent and tetrachlorethylene; cooperate with hydrocarbon solvent, tetrachlorethylene and transformer oil to adjust the cleaning volatilization speed, so that the solvent volatilization speed is maintained at 15-20min; naphthene Under the synergistic action of zinc acid zinc, barium petroleum sulfonate, hexadecane primary amine or octadecyl primary amine, dimethyl silicone oil, etc., a moisture-proof insulating protective film is formed and adsorbed on the metal surface to drive away the moisture on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com