Steelwire winder stress fluctuation control method and stress fluctuation control device employing same

A technology for controlling equipment and control methods, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., which can solve the problem of continuous and stable rotation speed of PCCP tube core and stress wheel, and reduce wire feeding of stress wheel of wire wrapping machine Speed, high-strength steel wire tensile stress fluctuations and other issues, to achieve the effect of stable physical and mechanical indicators, good internal quality, and small stress fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

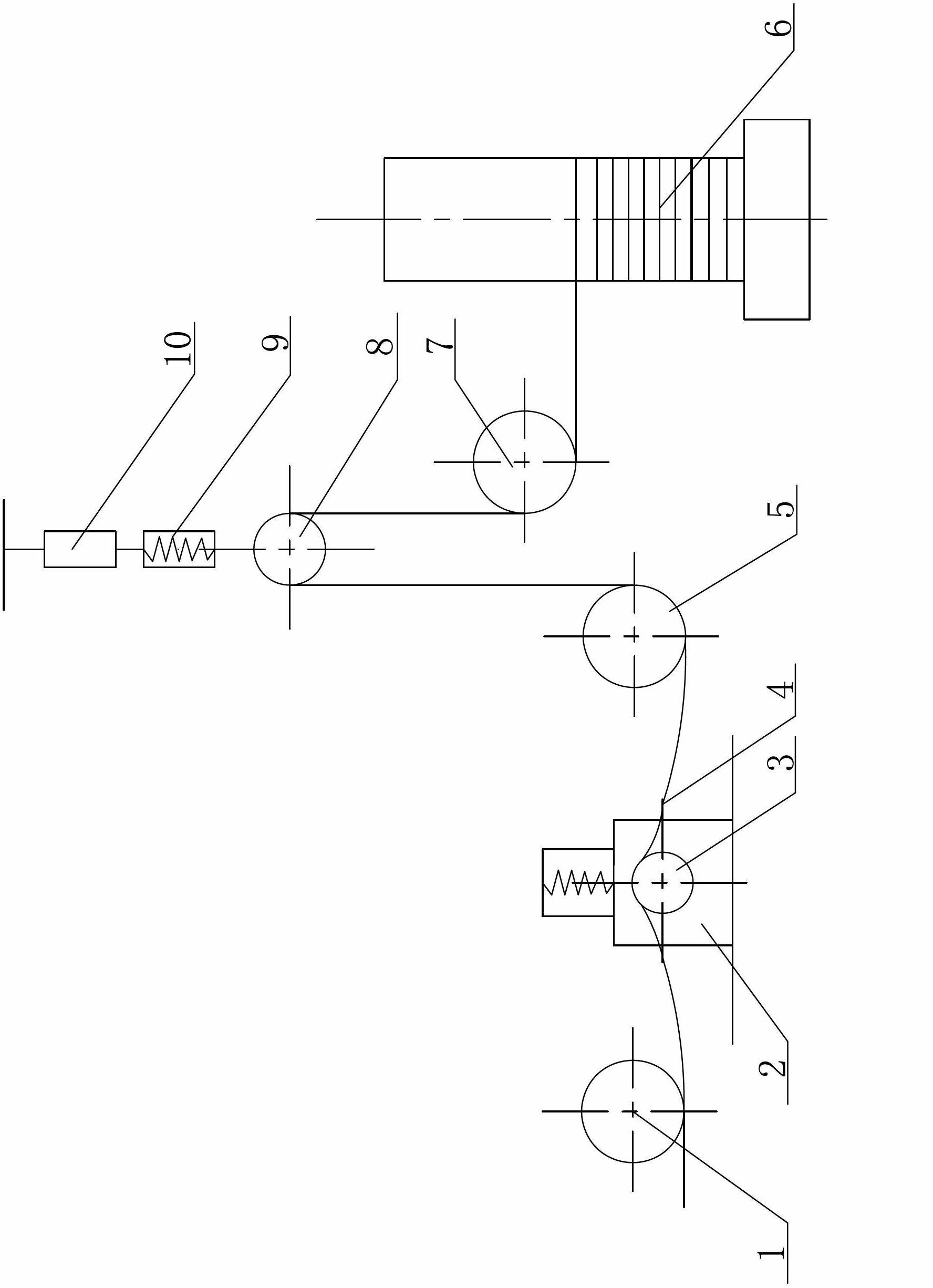

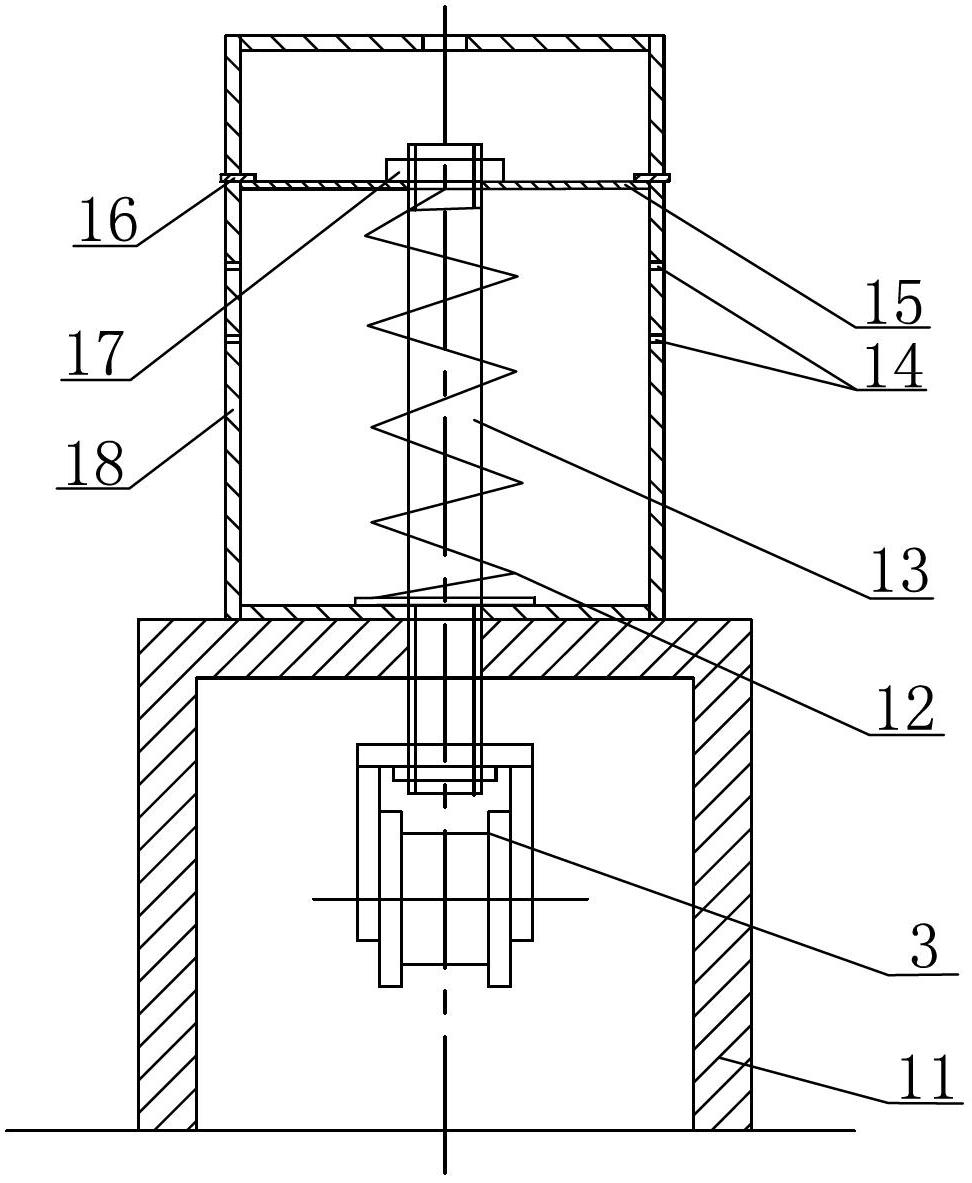

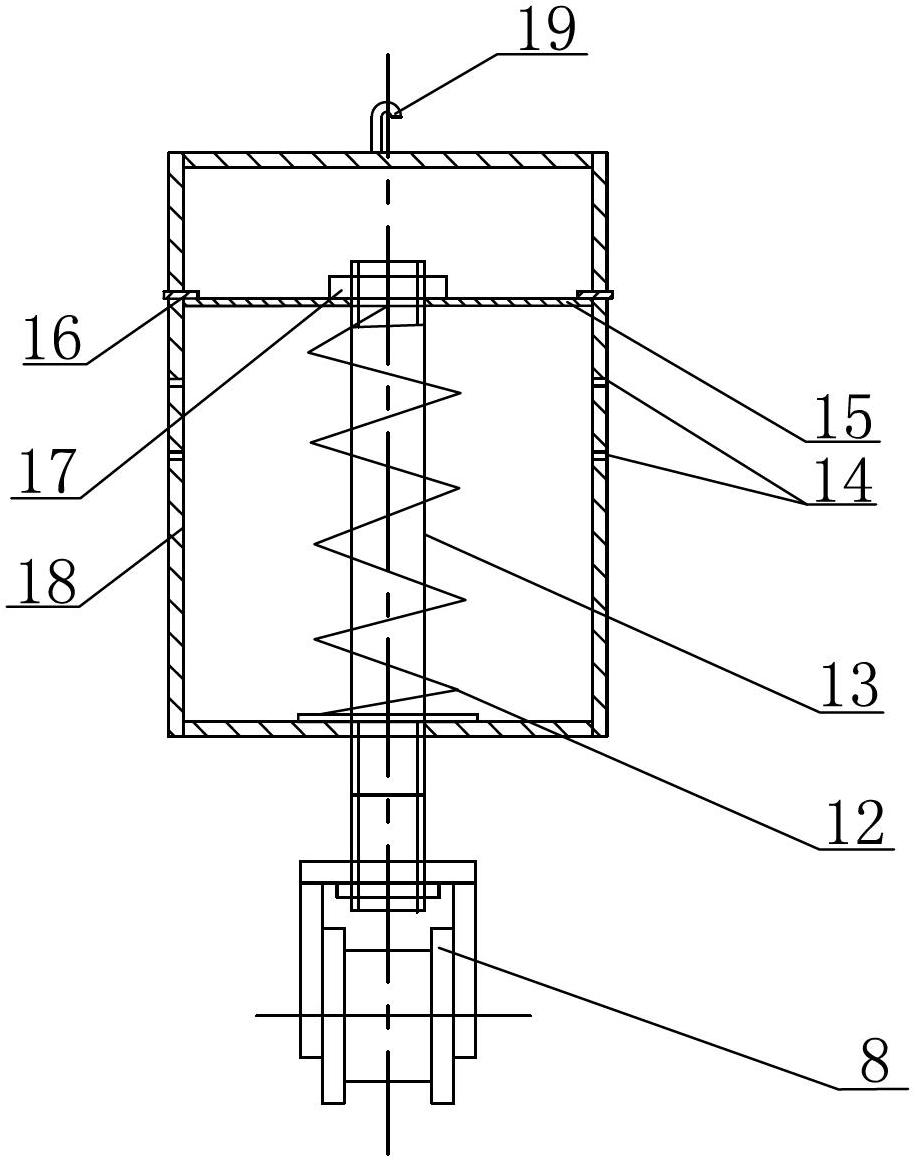

[0026] Such as figure 1As shown, the prestressed steel tube concrete tube vertical wire winding stress fluctuation control method of the present invention is to use two stress adjustment control devices and a shock-absorbing guide wheel 5 in combination to achieve a stable prestressed steel wire winding process. Stress fluctuations, increase the wire feeding speed of the wire winding machine, and improve production efficiency. The shock-absorbing guide wheel 5 is located between the stress wheel 1 of the wire winding machine and the guide wheel 7 of the wire winding machine. Among the two stress adjustment control devices, one is a base-type stress fluctuation control device 2, which is located on the stress wheel 1 of the wire winding machine. Between the anti-vibration guide wheel 5, it is required to make the corresponding underground concrete device founda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com