Printer

A technology for printers and elastic components, which is applied to printing devices, printing, transfer materials, etc., can solve the problem of reducing the pressing force in the contact area, achieve the effect of reducing the pressing force and realizing the cost of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

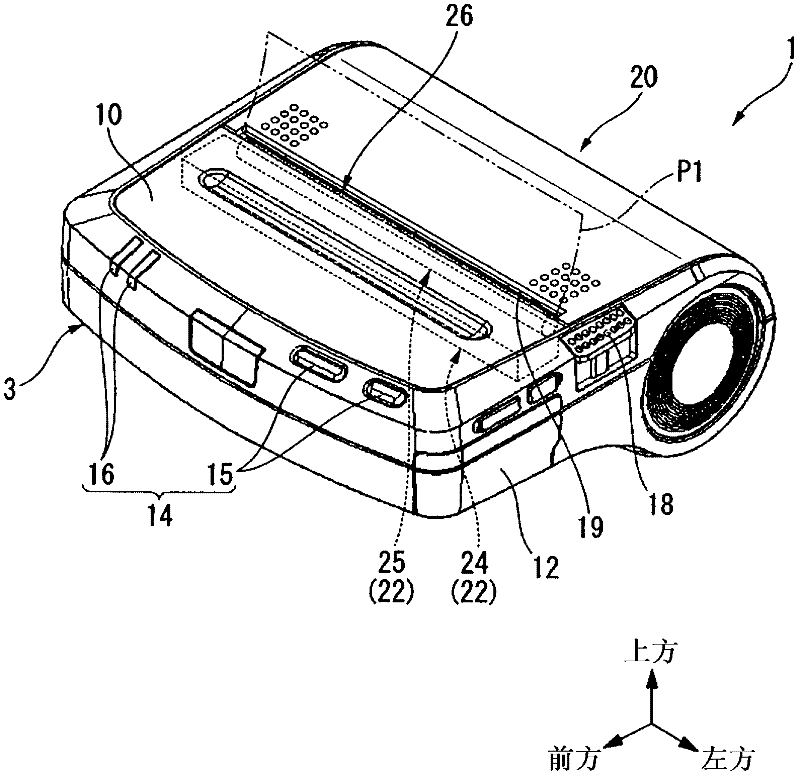

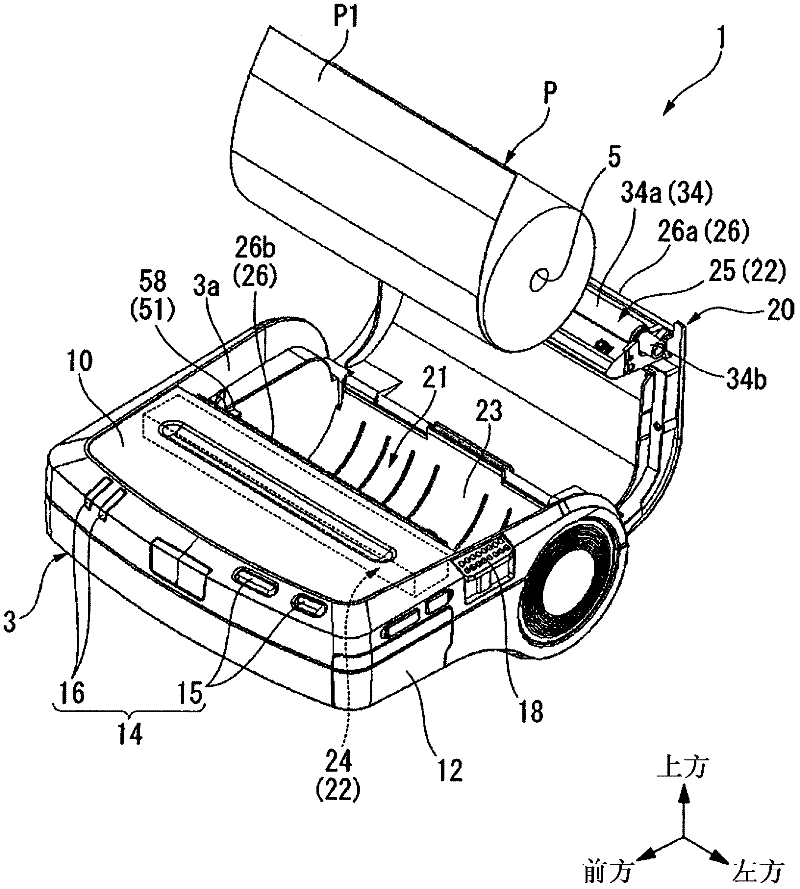

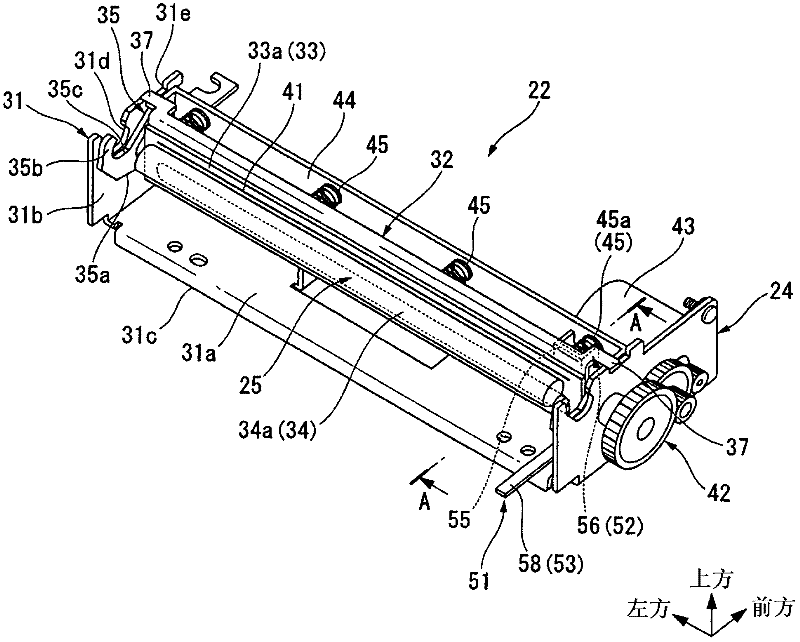

[0045] (thermal printer)

[0046] Next, embodiments of the present invention will be described based on the drawings. figure 1 is a perspective view showing a state where the paper cover in the thermal printer is in the closed position, figure 2It is a perspective view showing a state where the paper cover is in an open position. In addition, in the following description, in order to make the invention easier to understand, the illustrations are simplified by omitting part of the components, simplifying the shape, changing the scale, etc. as appropriate. In addition, in the drawings, the reference sign FR indicates the front, the reference sign LH indicates the left side, and the reference sign UP indicates the upward direction.

[0047] Such as figure 1 , figure 2 As shown, the thermal printer (printer) 1 is configured to be able to print on various types of recording paper P1 having different widths. Recording paper P1 is thermal paper that changes color when heated, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com