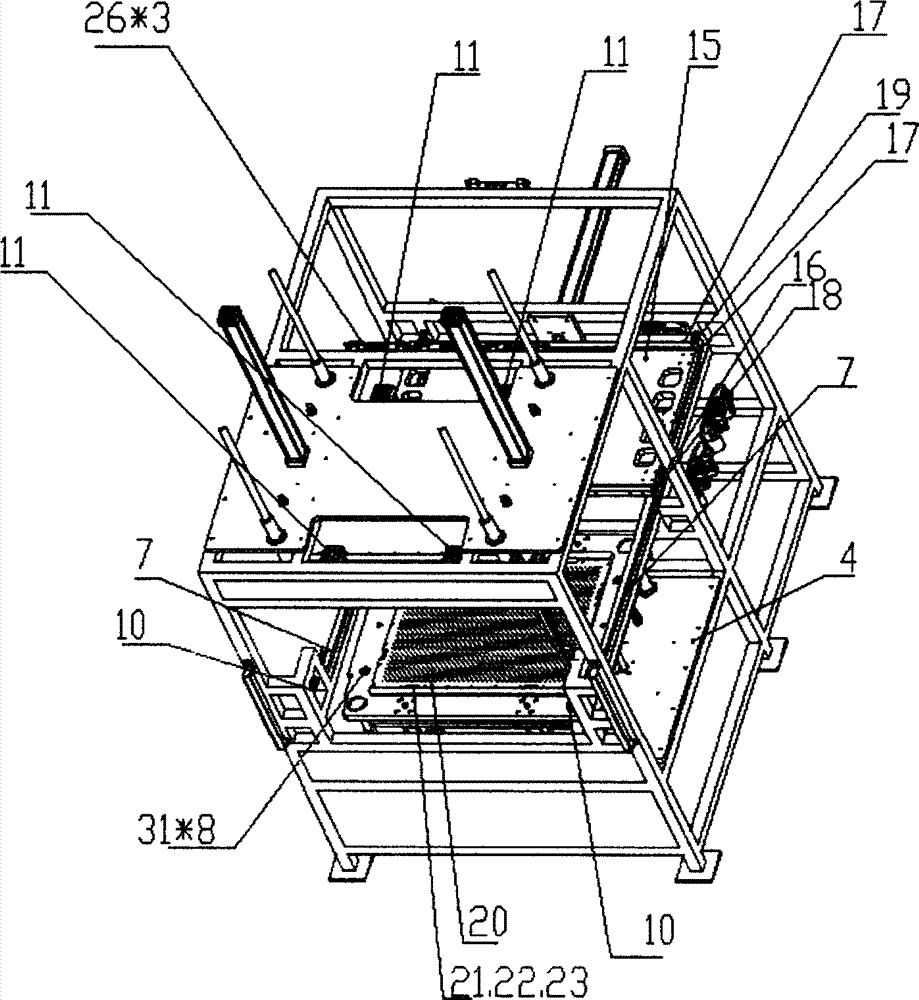

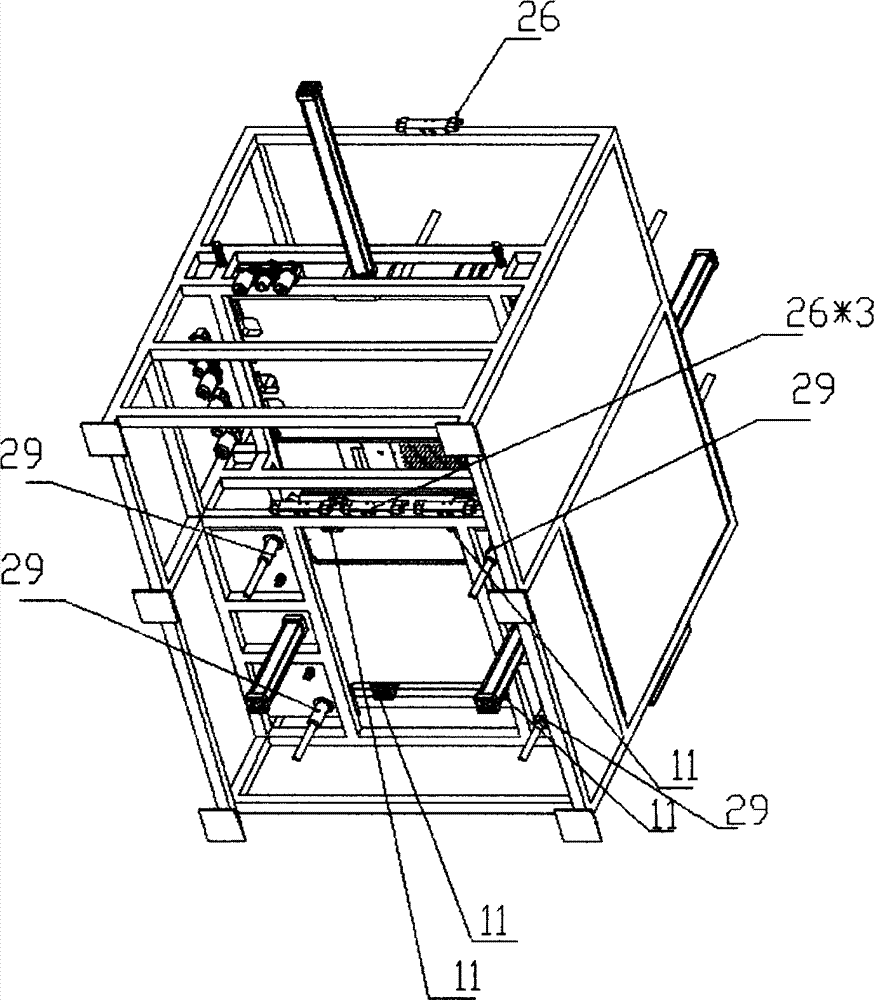

Automatic electrothermal pasting machine for pearl wool

A technology of pearl cotton and sticking machine, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of easy falling off of adhesive parts, low product qualification rate, harsh production environment, etc., to improve the production environment, Operational safety and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with the pearl cotton electric heating automatic gluing machine of the present invention, its working method will be described in detail. The method comprises the steps of:

[0037] 1) Input the processing temperature and air pressure parameters required for pre-obtaining the final product into the microcomputer;

[0038] 2) placing the lower part of the pearl cotton material to be processed in the groove of the pearl cotton material area to be processed, and placing the upper part of the pearl cotton material to be processed on its lower part;

[0039] 3) Start the gluing machine, and the area and the upper material adsorption device vertically compress the pearl cotton material to be processed under the action of the air pressure mechanism, so that the upper and lower needle-shaped adsorption devices are respectively embedded in the upper and lower parts of the pearl cotton material to be processed;

[0040] 4) Based on the pre-input parameters i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com