Robot arm stretching and swinging driving mechanism assembly

A technology of swing drive and robot arm, which is applied in the direction of claw arm, manipulator, manufacturing tool, etc., can solve the problems of single structure of reciprocating automatic spraying machine, no telescopic and swing function of robot arm, etc., and achieve convenient and fast protection and maintenance, structure Concise, program control simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The working principle of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

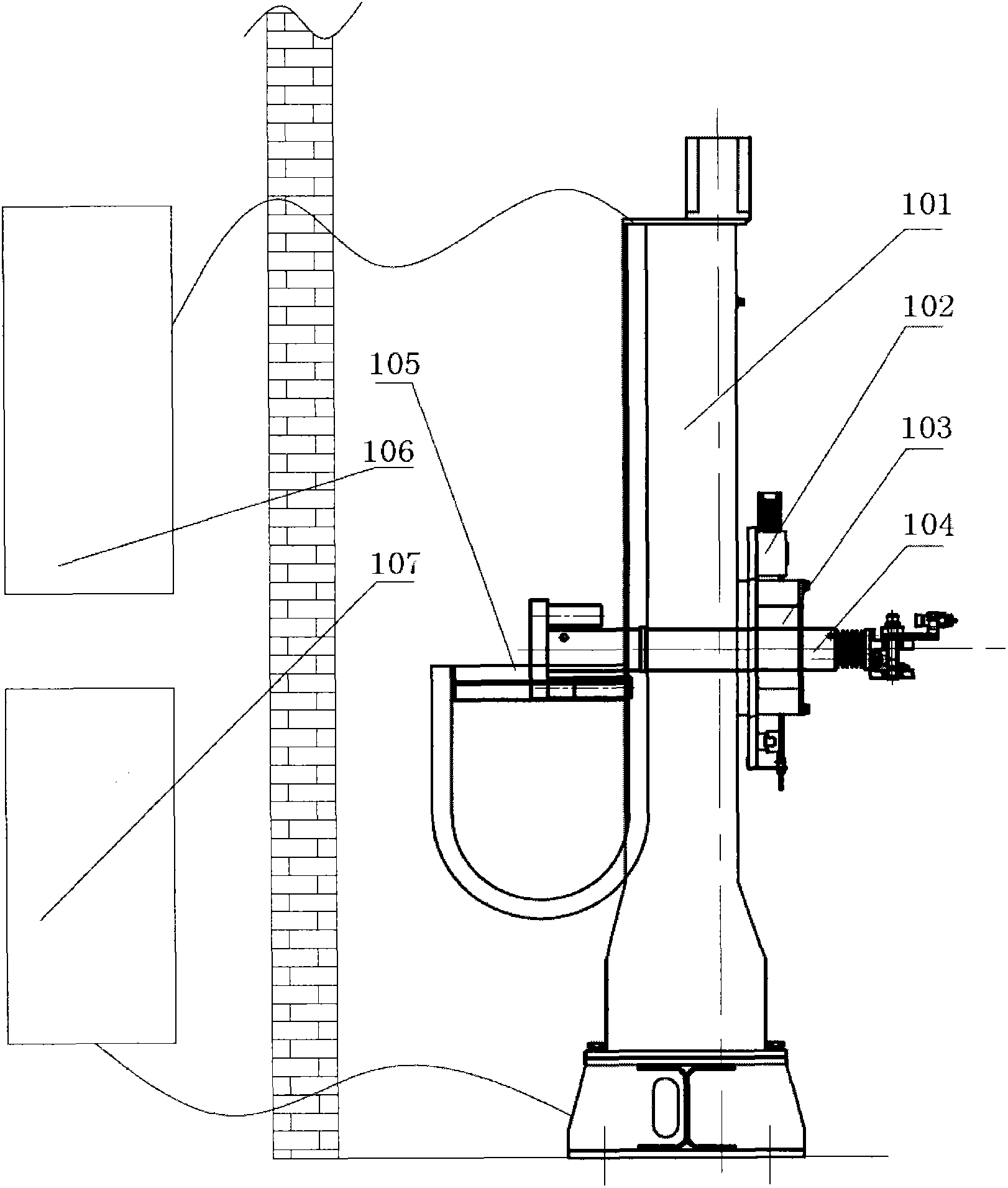

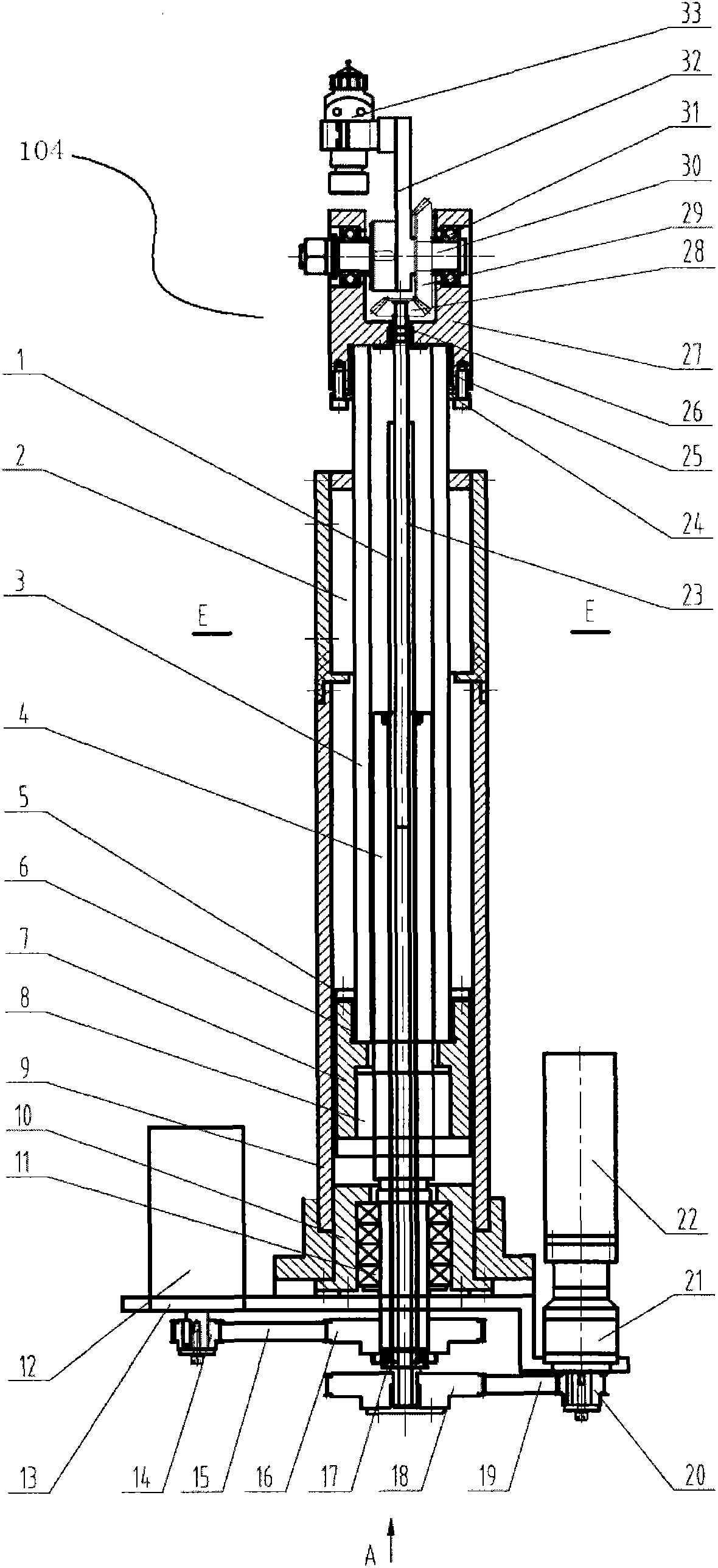

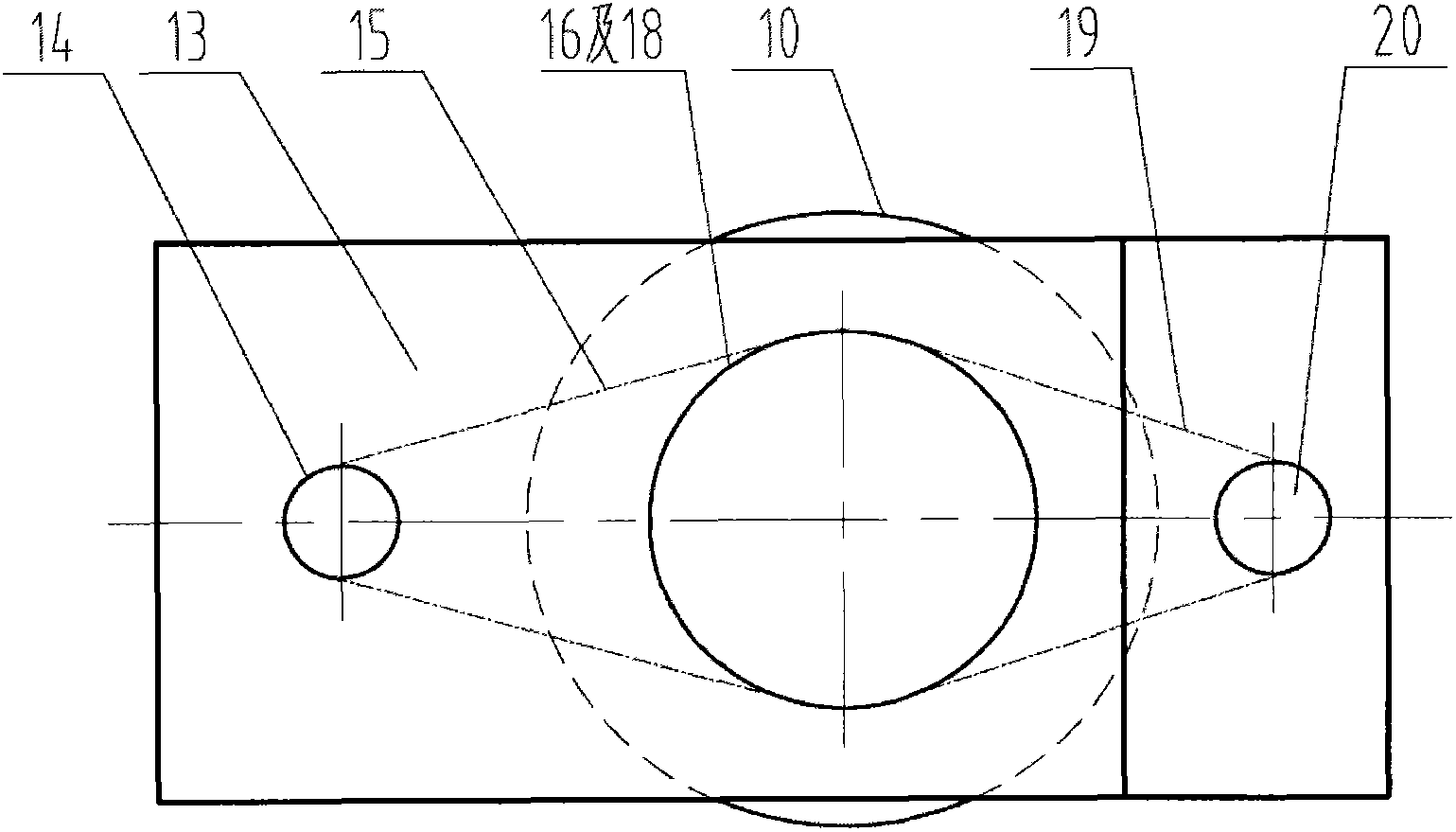

[0032] Such as figure 1 as shown, figure 1Shown is a painting robot with telescoping and swinging drive mechanism of the present invention, wherein the painting robot includes a lifting device 101 of the painting robot arm, a left and right moving device 102 of the painting robot arm, a rotating device 103 of the painting robot arm, stretching and swinging of the painting robot arm The driving mechanism assembly 104, the cable of the painting robot and the paint pipeline support 105, the electric control system 106 of the painting robot, and the paint transmission and mixing system 107 of the painting robot. Wherein the painting robot is installed on both sides of the assembly line in the painting workshop, and the paint delivery and mixing system 107 of the painting robot implements intelligent control on the paint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com