Combined clamp for drilling hole of torque tube assembling unit product

A technology of combined fixtures and assemblies, which is applied in the direction of drilling molds, clamping, and manufacturing tools for workpieces, can solve problems such as high manufacturing costs, user confusion, product out-of-tolerance, and scrapping, and achieve cost reduction, Avoid missed detection and calculation errors, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

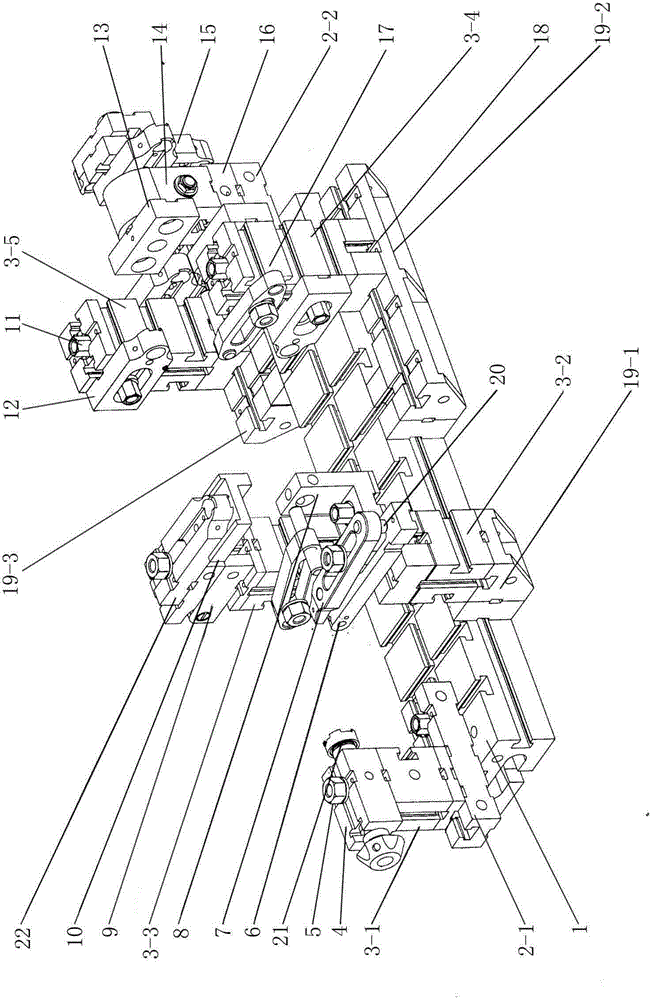

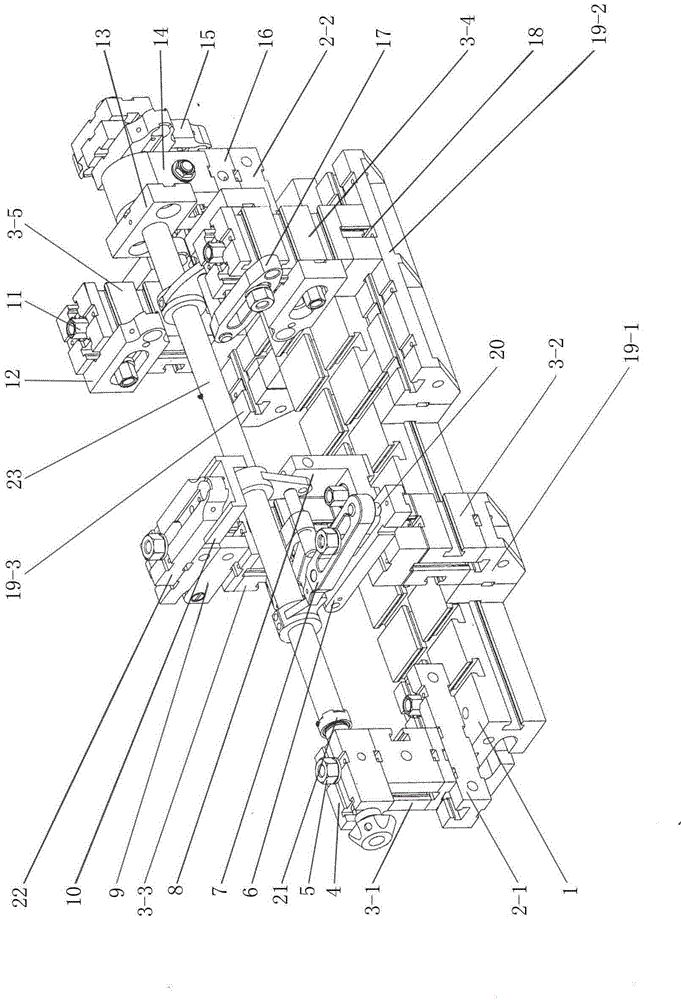

[0009] Such as figure 1 As shown, the combined fixture for drilling the torsion tube assembly product: the two ends of the base plate (1) are provided with an extension plate I (2-1) and an extension plate II (2-2). The base plate is used for the base of the jig, and the extension plate is used for the shortening and lengthening of the base of the jig.

[0010] Install support Ⅰ (3-1), movable positioning support (4) and shoulder nut Ⅰ (5) on the extension plate Ⅰ (2-1) in sequence, and the movable positioning support (4) is connected to the cylindrical positioning pin (21) . Cylindrical locating pins are arranged as locating pins of several different models, and during use, different cylindrical locating pins are selected according to different diameters of the torque tube. Cylindrical dowels are used for positioning and jacking.

[0011] The ribbed angle iron I (19-1) is fixed on the foundation plate (1), and the ribbed angle iron I (19-1) is successively installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com