Reflow soldering equipment

A reflow soldering and equipment technology, which is applied in metal processing, electrical components assembly printed circuit, etc., can solve the problems of easy deformation, board dropping, and unstable transportation, etc., and achieve the effect of improving board dropping, reducing energy consumption, and facilitating transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

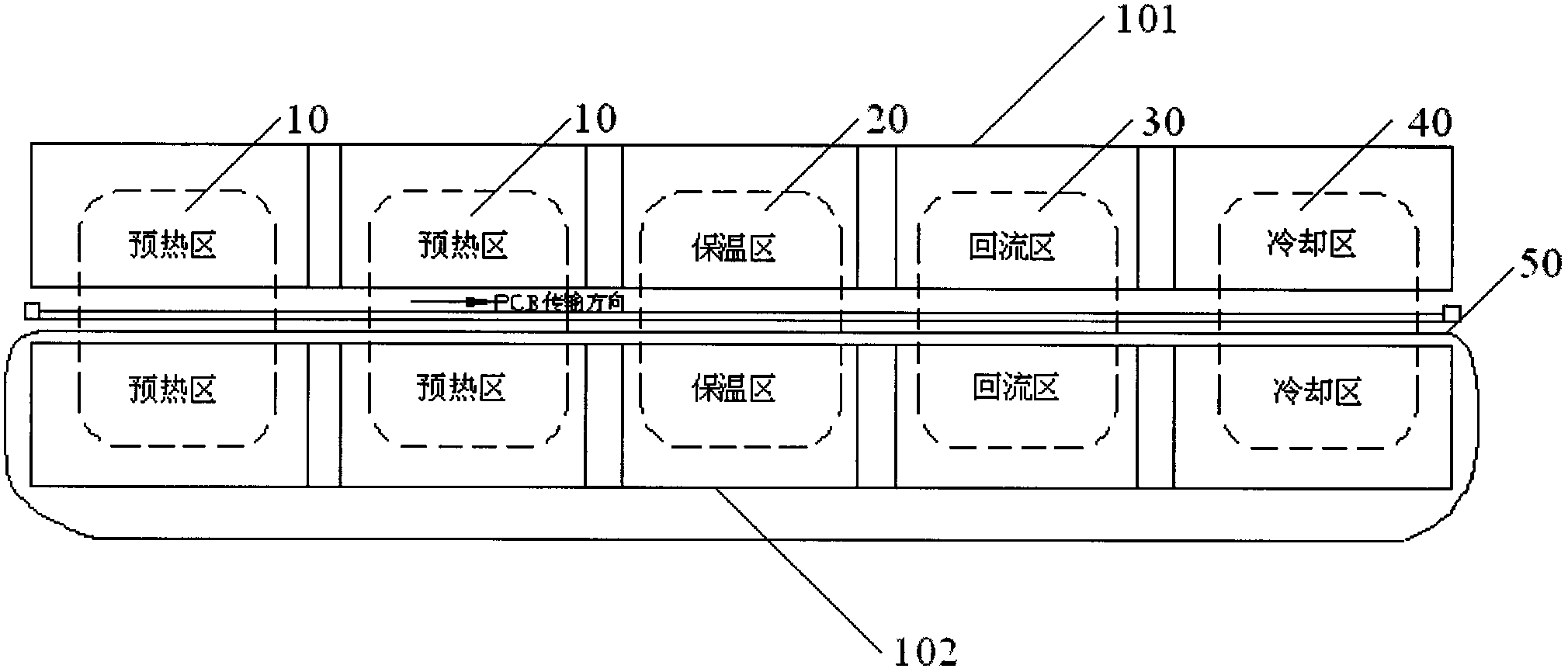

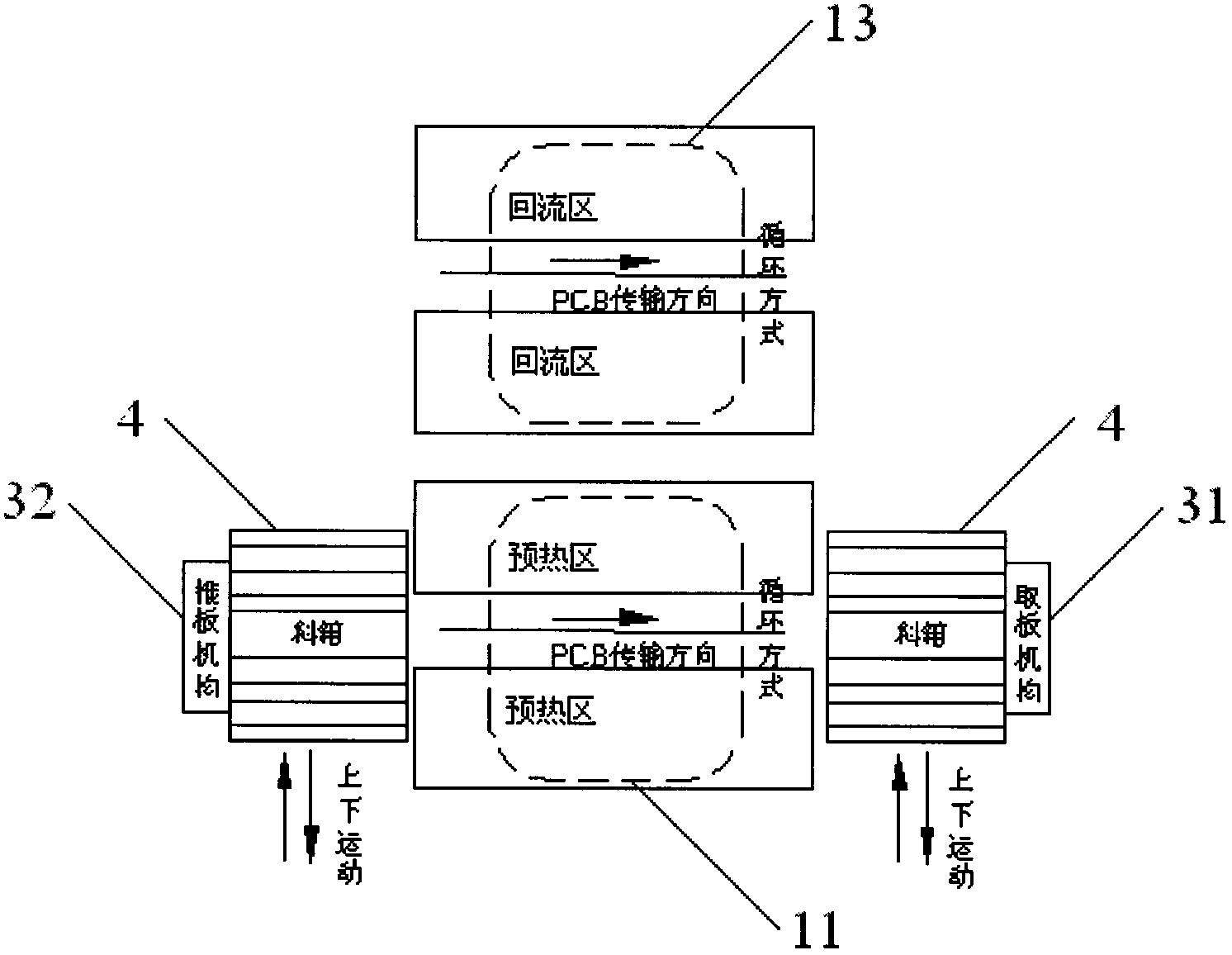

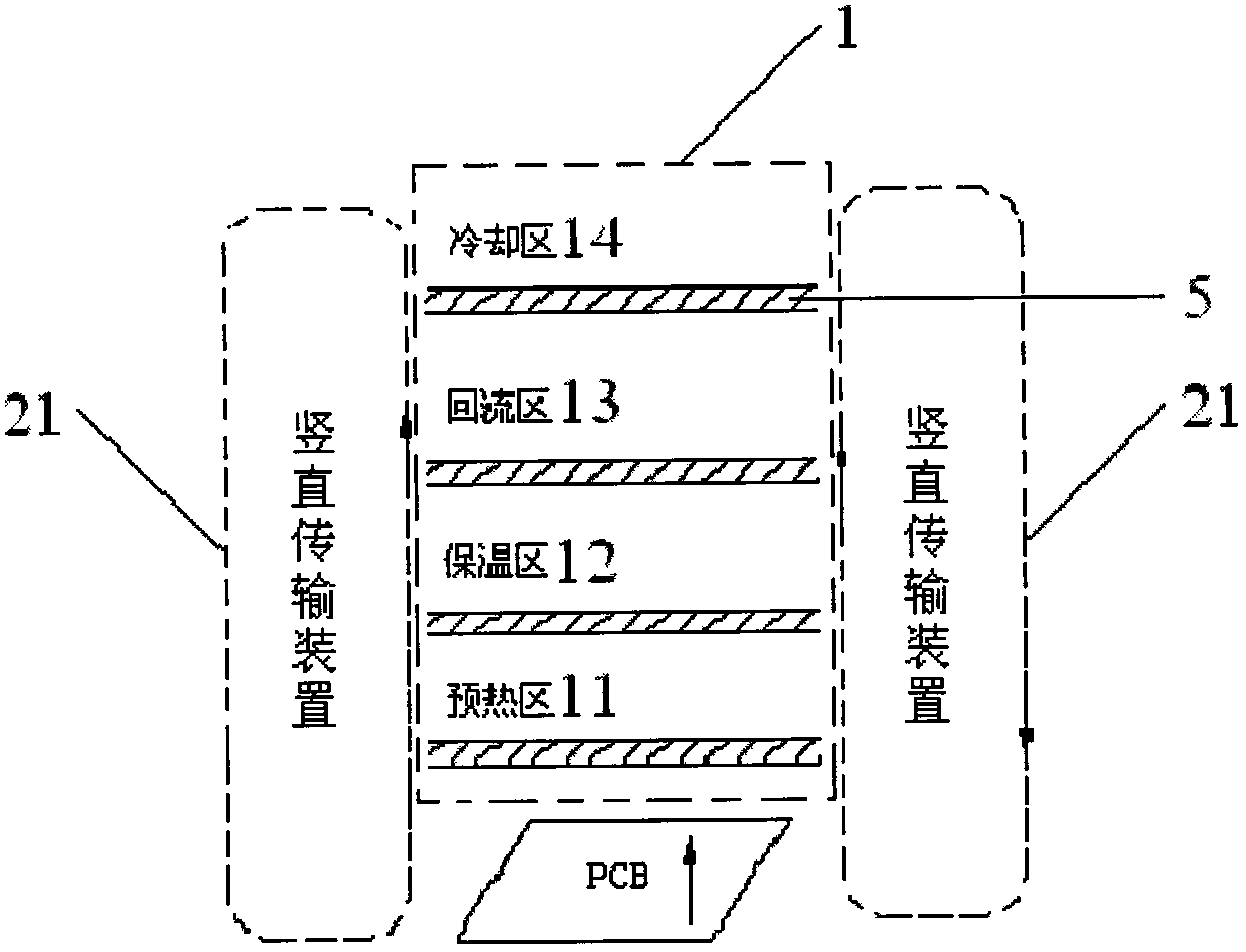

[0024] Refer below Figure 2-Figure 4 Describe in detail an embodiment of the tower reflow furnace provided by the present invention; as shown in the figure, this embodiment mainly includes a plurality of temperature zones 1 and a PCB transmission mechanism 2 for transferring PCB boards in the multiple temperature zones 1 Among the multiple temperature zones 1, at least two temperature zones 11, 13 are arranged vertically up and down, and the PCB transmission mechanism 2 at least includes a vertical transmission guide rail 21 for vertically transporting PCBs between the temperature zones arranged up and down. .

[0025] In addition, the PCB transmission mechanism 2 also includes a horizontal transmission guide rail (not shown in the figure) for horizontally transporting the PCB in each temperature zone 2 .

[0026] In addition, the entrance and exit of each temperature zone 1 are respectively provided with a plate picking mechanism 31 and a plate pushing mechanism 32 for pick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com