Ultrasonic probe and method for manufacturing ultrasonic probe

An ultrasonic and substrate technology, applied in ultrasonic/sonic/infrasonic diagnosis, ultrasonic diagnosis, infrasonic diagnosis, etc., can solve the problems of insufficient pressurization, FPC cannot follow deformation, insufficient rigidity of PCB, etc., and achieve the effect of solving the insufficient pressurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

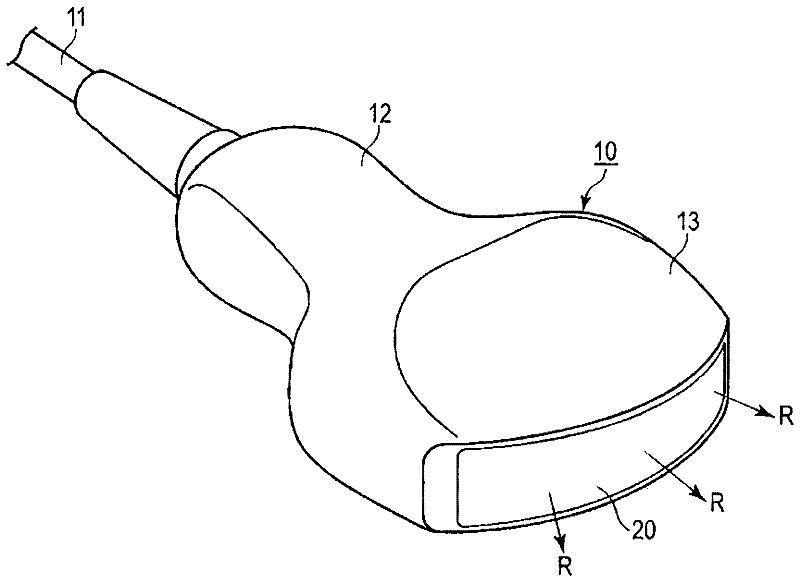

[0026] figure 1 It is a perspective view showing the ultrasonic probe 10 according to the first embodiment. figure 2 It is a cross-sectional view showing essential parts of the ultrasonic probe 10. Figure 3A It is a plan view showing the substrate 30 included in the ultrasonic probe 10. Figure 3B , 3C 3D is a plan view showing the second end 42 of the first FPC 40 connected to the substrate 30. Figure 4A It is a cross-sectional view schematically showing the connection part between the FPC 40 and the substrate 30 of the ultrasonic probe 10. Figure 4B is true Figure 4A A cross-sectional view of the K part indicated by the continuous double dash in the enlarged and displayed section. In these figures, R represents the ultrasonic irradiation direction.

[0027] The ultrasonic probe 10 is a convex 2-D array ultrasonic probe attached to an ultrasonic diagnostic apparatus through a cable 11. The ultrasonic probe 10 includes a handle portion 12 held by an operator and a head 13 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com