Method for manufacturing organic electroluminescent element

An electroluminescent, electromechanical technology, applied in the field of producing organic electroluminescent devices, to achieve the effect of suppressing total reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

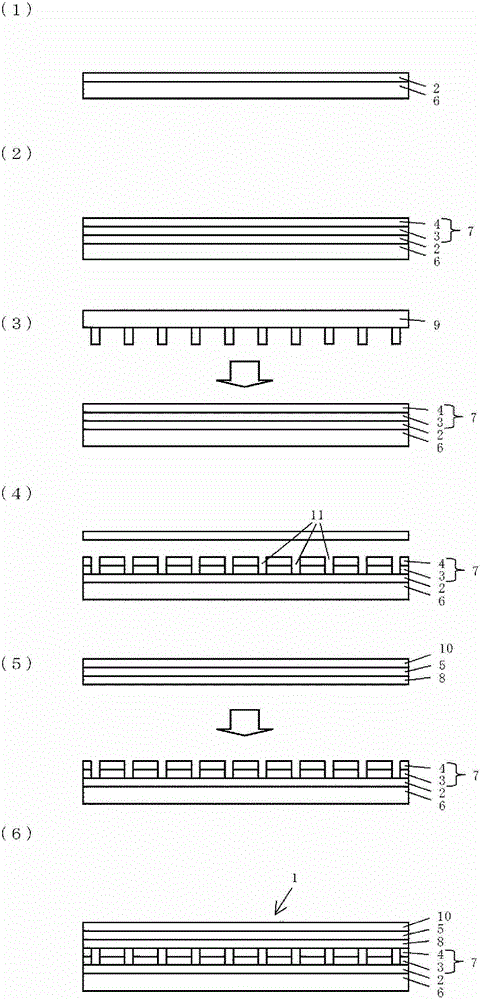

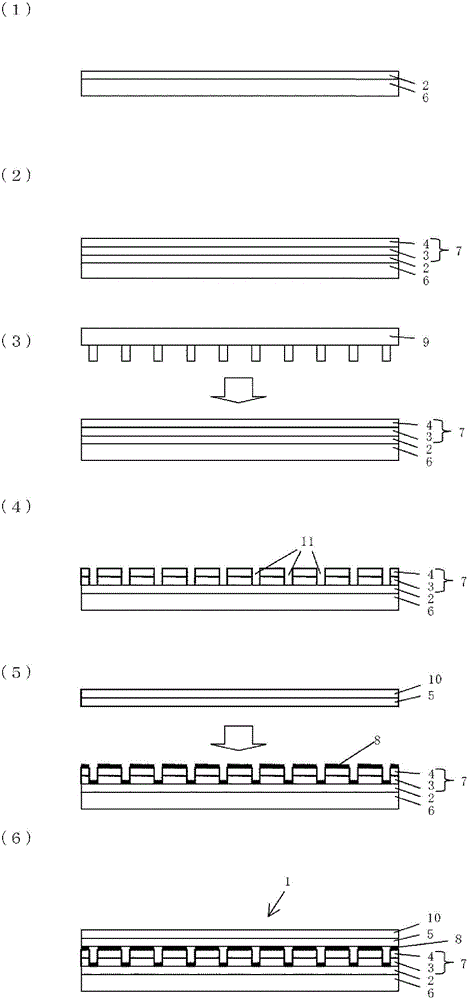

Method used

Image

Examples

Embodiment

[0156]

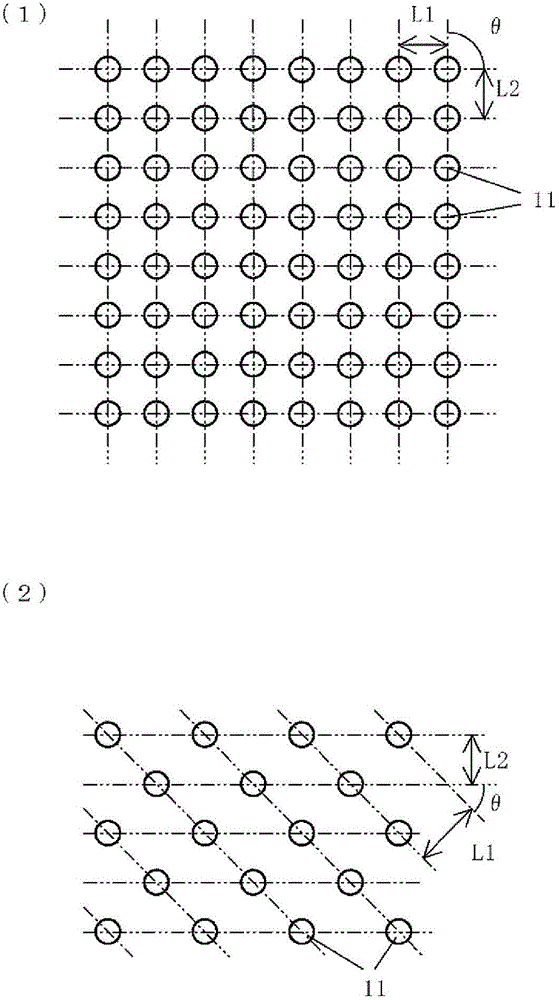

[0157] Using an electron beam (EB) lithography equipment, patterning is performed on the part made of Si to form a plurality of periodic two-dimensional cylinders to prepare the model 12 made of Si. Figure 4 It is a diagram schematically showing the model. Figure 4 (1) The top view of the model is shown schematically, and Figure 4 (2) A cross-sectional view of the model is schematically shown. The size of the model in plan view is 20mm×20mm, and has a patterned structure of a plurality of cylinders in its central part. The area having the structure with a plurality of patterned cylinders has a size of 10 mm×10 mm in the center of the model in plan view. The dimensions of each cylinder are: the diameter Lb is 150 nm and the height Ld is 160 nm. The distance La between the central axes of adjacent cylinders is 300 nm. In addition, the angle θ between the vertical bar and the horizontal bar represented by the chain-shaped double dashed line is 60°. The interval Lc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com