Hybrid drive train

A driving system and automatic technology, applied in the direction of hybrid vehicles, motor vehicles, electric vehicles, etc., can solve the problems of poor performance, drag loss, increased motor efficiency and battery efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

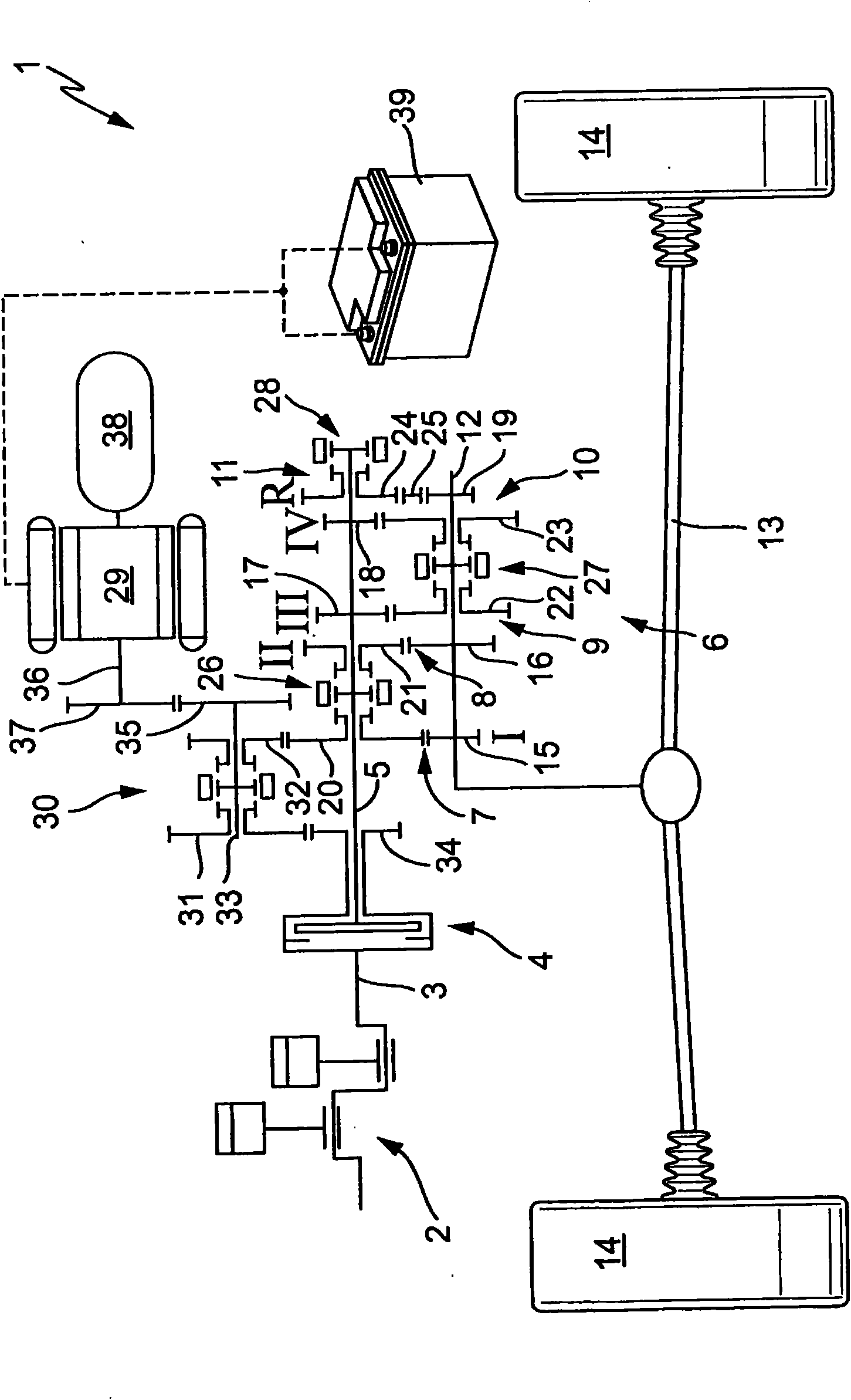

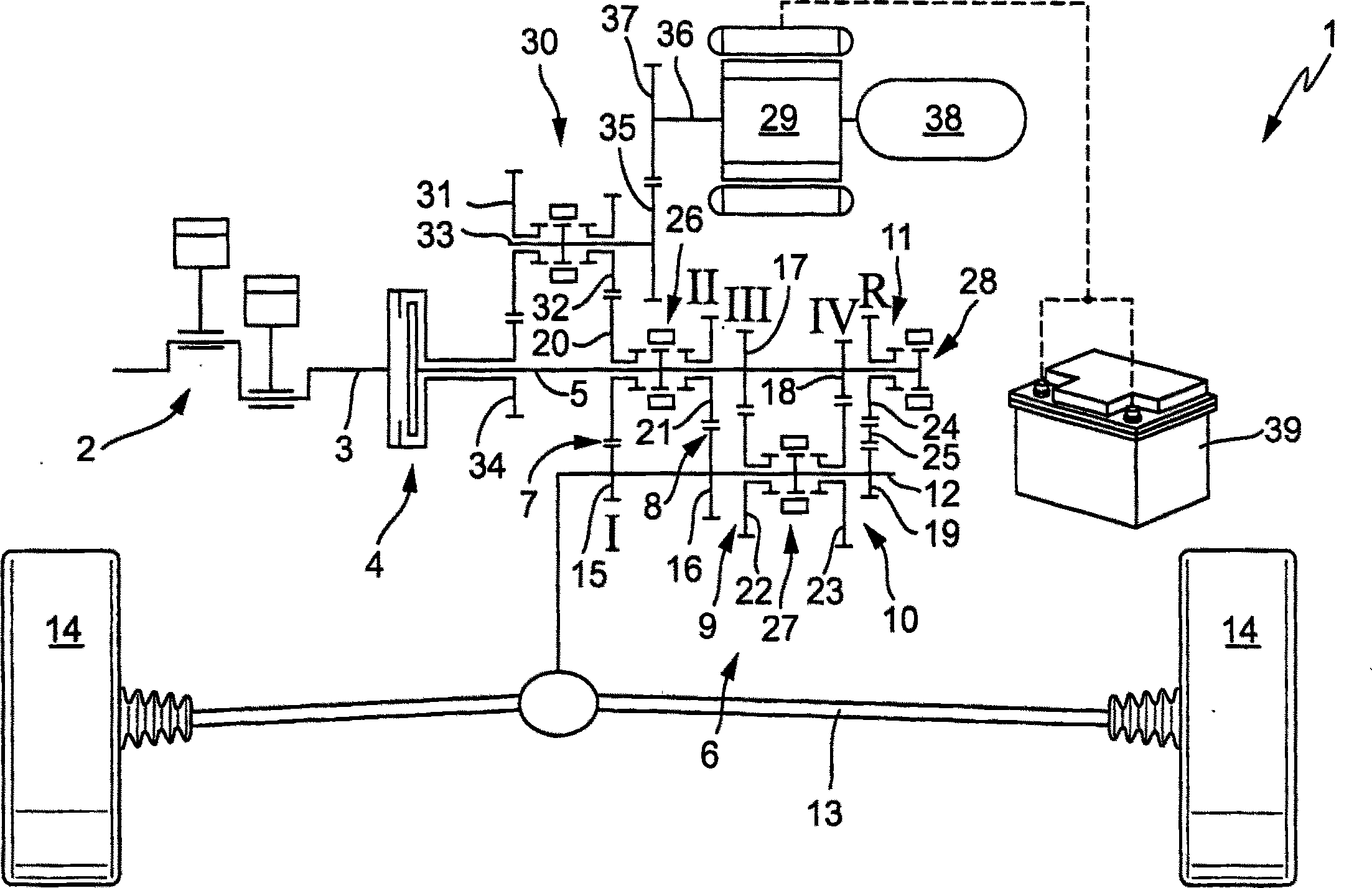

[0013] figure 1 The drive train 1 is shown in a schematic diagram, which does not show the actual geometrical arrangement of the individual parts for the sake of a better overview of the layout of the transmission. The drive train 1 comprises an internal combustion engine 2 - here in the form of an internal combustion engine - having a crankshaft 3 on which an automatically operated friction clutch is fixedly received. Its output is fixedly connected to the transmission input shaft 5 of the automatic shift transmission 6 . In the shifting transmission 6, a plurality of gear pairs 7, 8, 9, 10, 11 for forming gears I, II, III, IV, R are provided between the transmission input shaft 5 and the transmission output shaft 12, wherein the gears Bit R is the reverse gear, and each of these gear pairs is connected with the drive wheels 14 through the differential device 13 .

[0014] Gear pairs 7, 8, 9, 10, 11 each pass through a fixed gear 15, 16, 17, 18, 19 and an idler gear 20, 21,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com