Waterproof structure of wire leading portion

A waterproof structure, electric wire technology, applied in the direction of circuits, vehicle parts, electrical components, etc., can solve the problems of poor operability, rubber cap movement, etc., and achieve the effect of reliable position, improved operability, and uncomplicated assembly work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

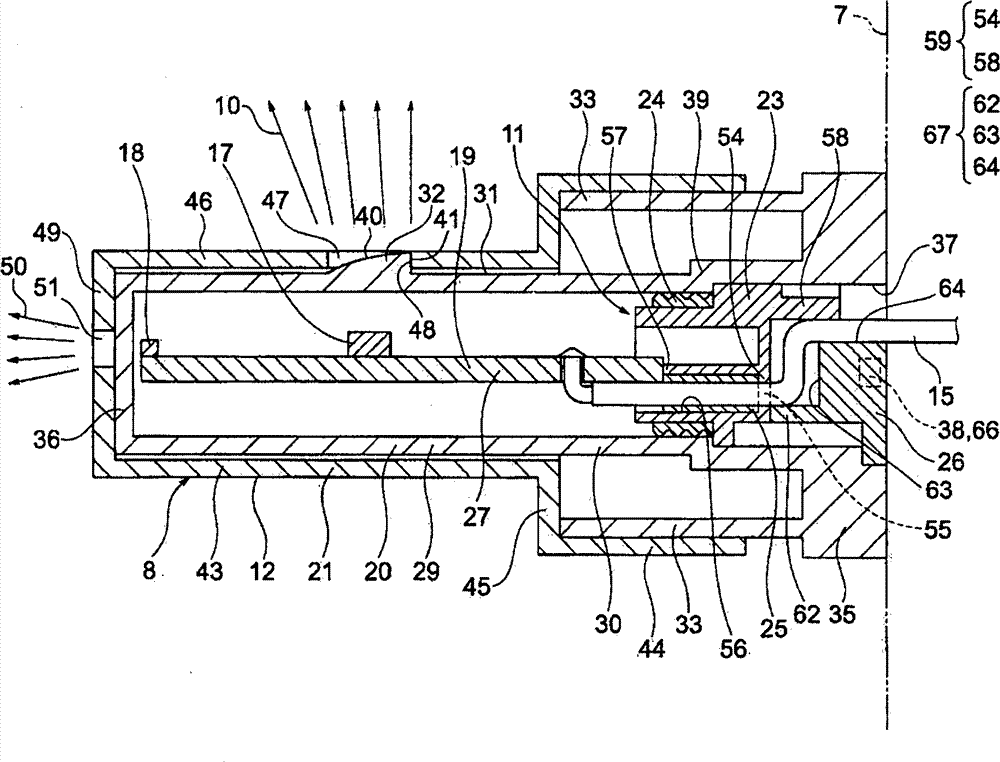

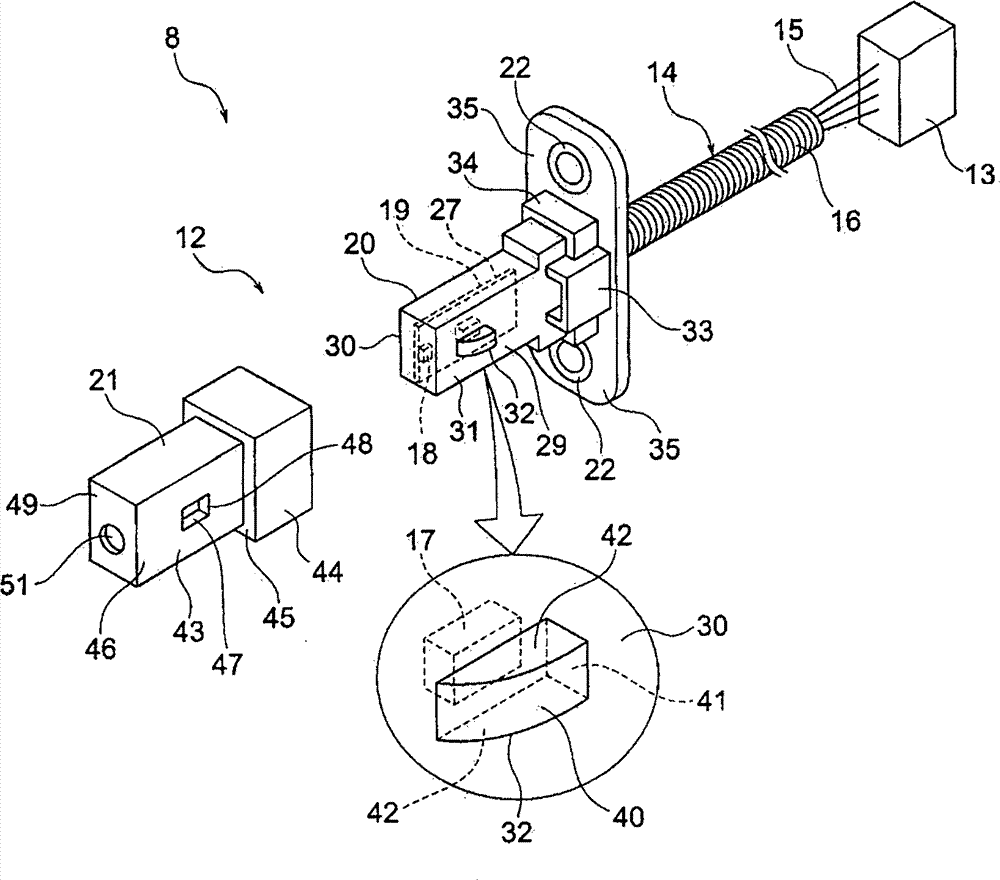

[0029] A waterproof structure is adopted in which the outer surface of the seal holder and the inner surface of the housing are sealed by the seal with respect to the wire lead-out portion, and the rubber cap accommodation chamber of the seal holder and the wire pass through Rubber cap seal. Furthermore, a waterproof structure is adopted in which the rubber cap is held by the cross section of the circuit board and the inner surface of the rubber cap detachment prevention wall. Furthermore, an electric wire maintaining structure is employed in which the electric wire drawn out from the outer surface of the rubber cap drop-off preventing wall is maintained in a bent state by the seal holder and the respective bend maintaining portions of the holder.

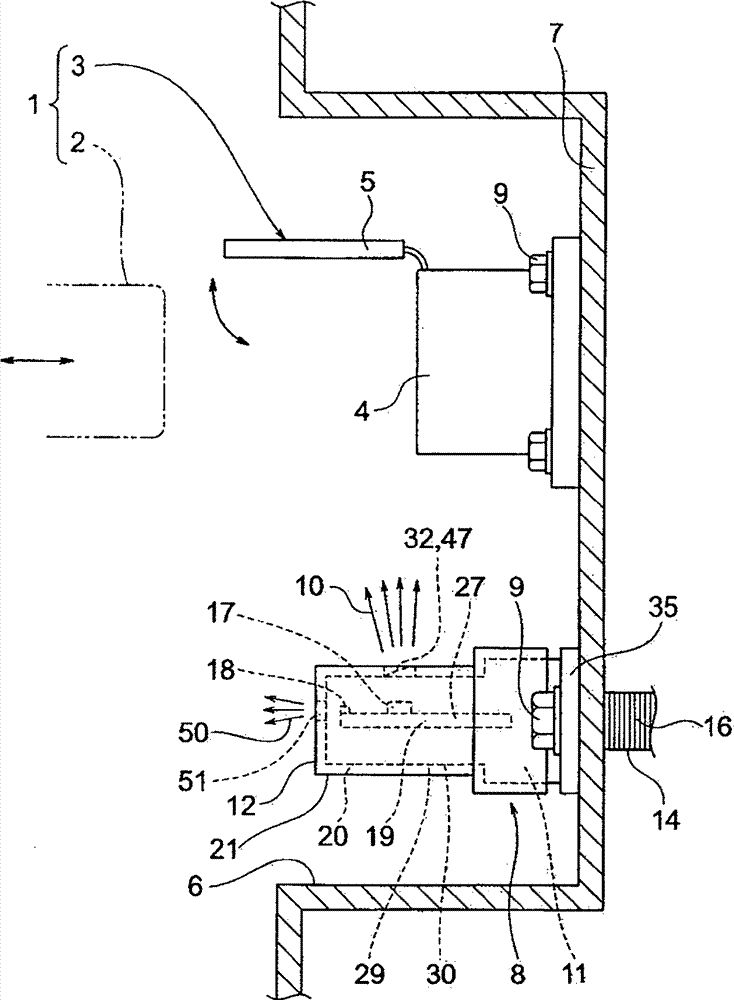

[0030] Hereinafter, embodiments will be described in detail with reference to the accompanying drawings. figure 1 is a view showing the arrangement of the lighting unit and the charger connector employing the waterproof structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com