Intelligent hanging-connection trigger mechanism of grounding terminal

A grounding terminal and trigger mechanism technology, applied in connection, conductive connection, electrical component connection, etc., can solve problems such as operator safety accidents, inability to safely supervise on-site operations, etc., achieve reliable work, facilitate remote monitoring of on-site operations, and facilitate reported effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

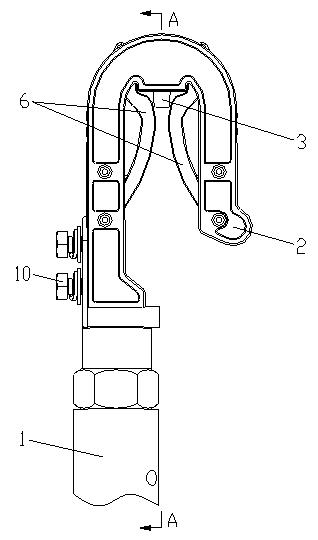

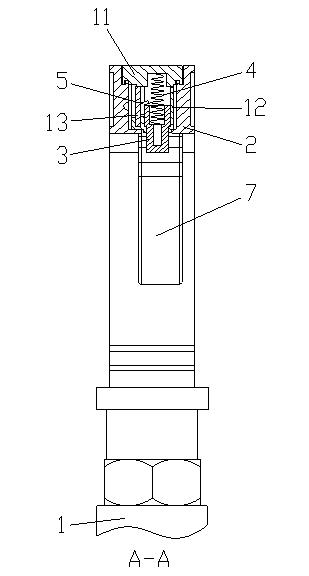

[0022] Embodiment 1: The sensor is a mechanical trigger switch. The mechanical trigger switch is composed of a trigger switch cap 3 that can move up and down and a trigger switch 5 for sensing the movement of the trigger switch cap 3. The trigger switch cap 3 is connected to the hook 2 A return spring 4 is provided between the bent parts of the trigger switch cap 3 so that it is in a spring-open state when it is not triggered.

[0023] In the first embodiment, the curved part of the hook 2 is provided with a gland 11 for positioning the upper end of the return spring 4, and the curved part of the hook 2 is provided with a trigger switch cap mounting seat 12, and the trigger switch cap mounting seat 12 is provided with a trigger switch mounting seat 13; during hooking operation: the trigger switch cap 3 moves upwards and touches the trigger switch, and the trigger switch 5 obtains the hooking action information and feeds it back to the acquisition device, and the acquisition dev...

Embodiment 2

[0024] Embodiment 2: The curved part of the hook 2 is provided with a trigger switch cap 3 that can move up and down, and there is a device between the trigger switch cap 3 and the curved part of the hook 2 so that the trigger switch cap 3 is bounced off when it is not triggered. The return spring 4 of the state, the Hall device or the magneto-sensitive resistor triggers the movement of the switch cap 3 to determine the hooking state of the grounding wire. In other words, in the second embodiment, the trigger switch 5 in the first embodiment is replaced by a sensor device such as a Hall device or a magnetoresistor that can effectively detect metal proximity. At this time, the trigger switch cap 3 is at least partially made of metal.

[0025] In the second embodiment, the curved part of the hook 2 is provided with a gland 11 for positioning the upper end of the return spring 4, and the curved part of the hook 2 is provided with a trigger switch cap mounting seat 12, and the trig...

Embodiment 3

[0026] Embodiment 3: The sensor is a Hall device or a magneto-sensitive resistor that can effectively detect metals close to it, and collects the hooking action information through changes in the electric field or magnetic field. Improve detection sensitivity or a permanent magnet with a large magnetic energy product; in other words, in the third embodiment, the mechanical trigger switch in the first embodiment is replaced by a Hall device or a magneto-sensitive resistor. When the hook 2 hooks the connecting wire, the Hall device or the magneto-sensitive resistor obtains the hooking action information and feeds it back to the acquisition device. The acquisition device can send the location, time, personnel and operation conditions of the on-site operation to the remote monitoring through the wireless communication module. center.

[0027] In Embodiment 1, Embodiment 2 and Embodiment 3, the inside of the hook 2 is provided with a clip 6 for clamping the grounding wire. The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com