Holding structure of intervening member, intervening member, and wobbling-prevention member

One component, one technology, applied in the direction of connecting components, mechanical equipment, transmission parts, etc., can solve the problems of reduced workability of rubber gaskets, high compressive loads, difficult clamping components, etc., to prevent the reduction of assembly workability, Reduced compressive load and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, embodiments of the present invention will be described based on the drawings.

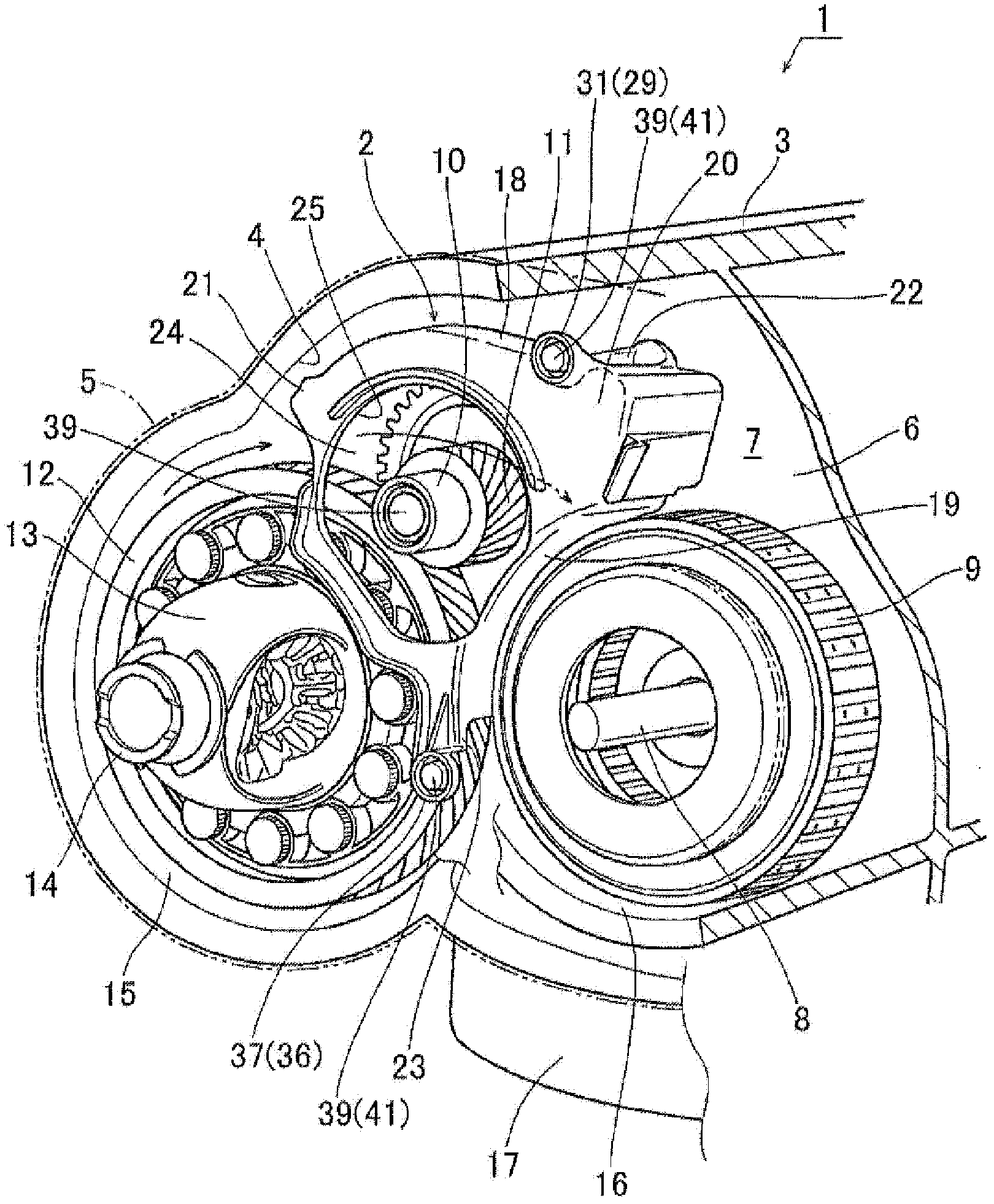

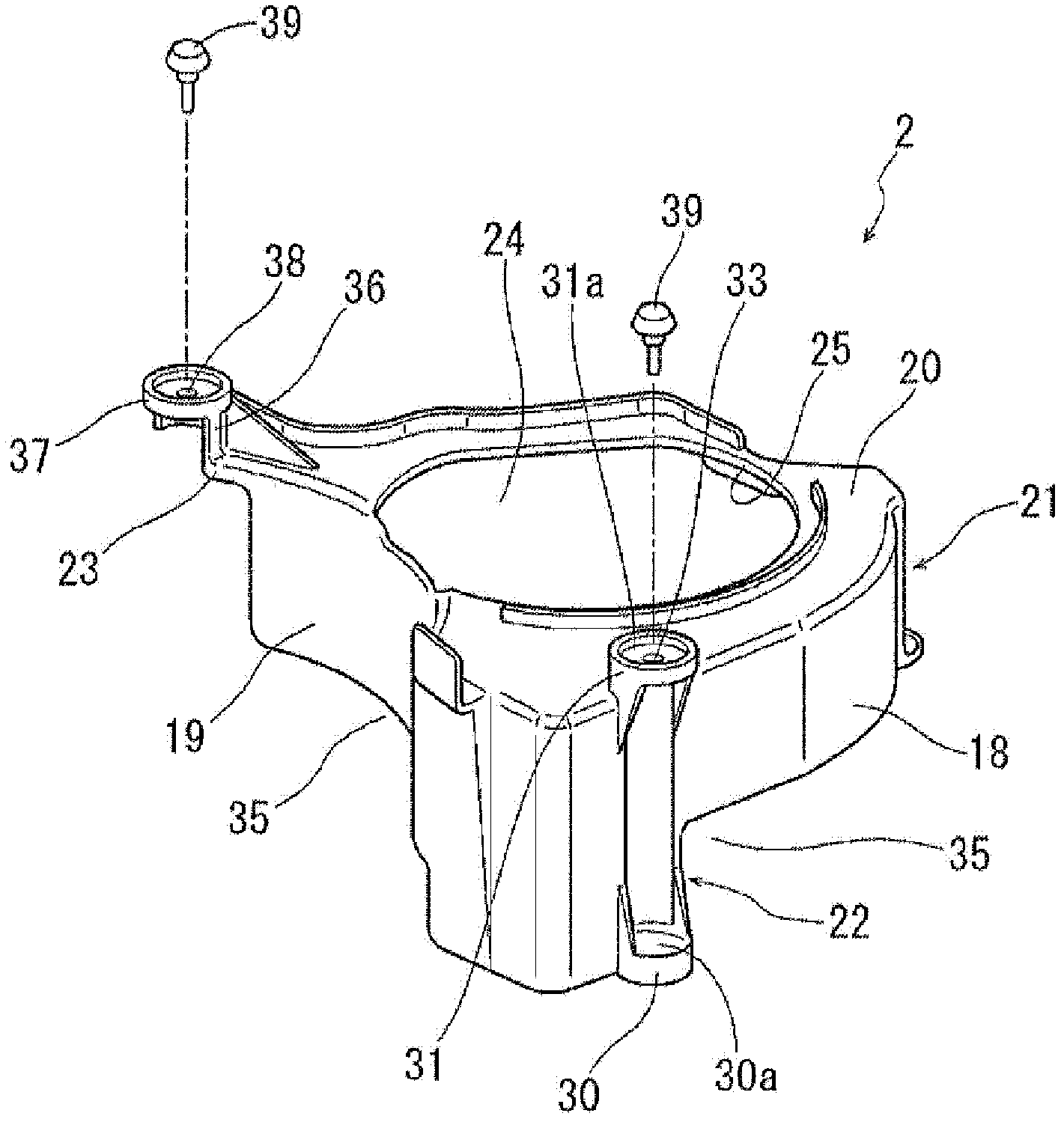

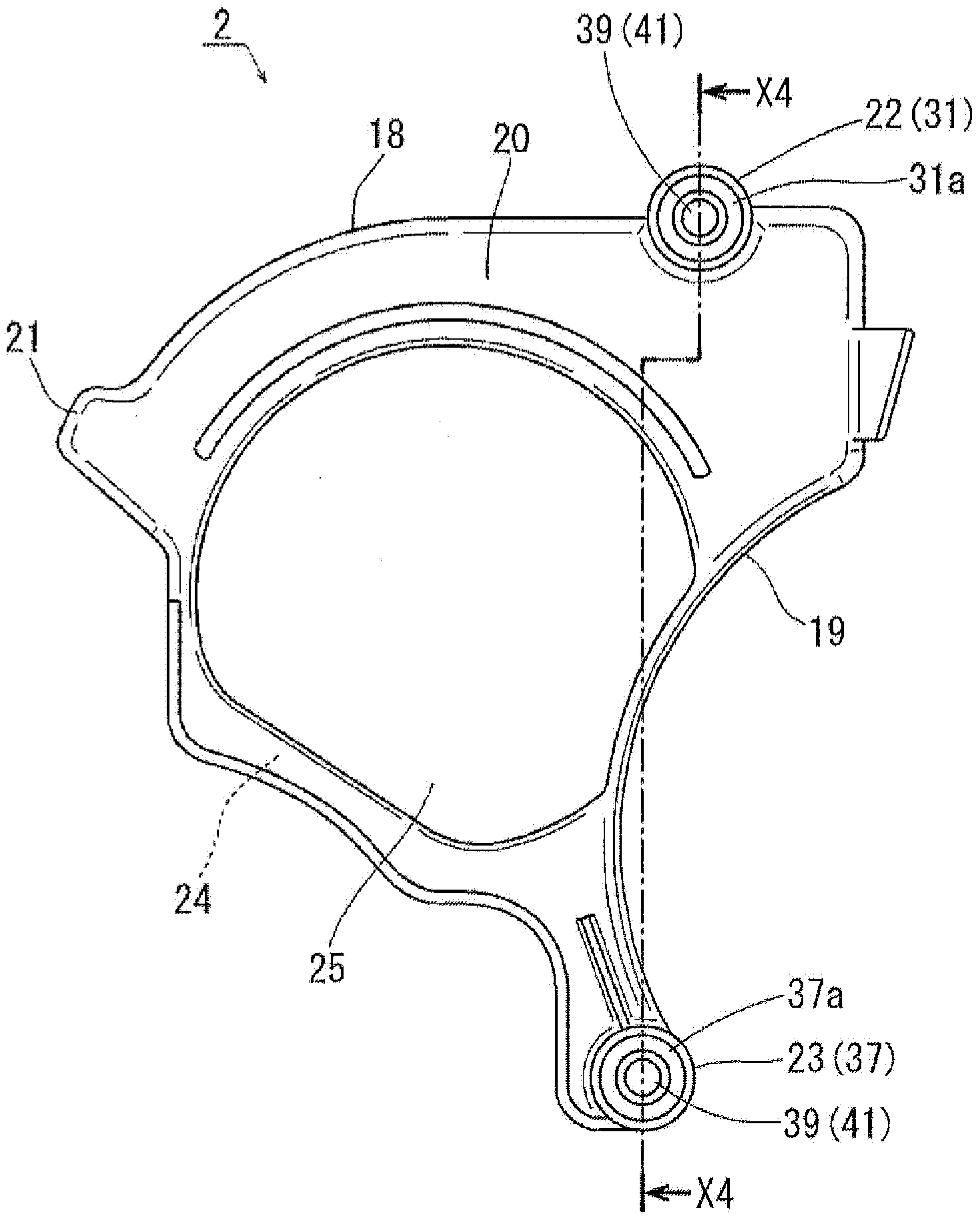

[0054] figure 1 The automatic transmission 1 incorporating the baffle 2 of the embodiment is shown. The automatic transmission 1 has a cylindrical transmission case (second member) 3, and an opening 4 on one side thereof is defined by a torque converter housing wall (first member, one side member: in figure 1 Indicated by a phantom line) 5 is blocked, and the opening (not shown) on the other side is blocked by an end cap (not shown). In the transmission case 3, an intermediate wall 6 is provided as a partition wall, and an input shaft for inputting power from the torque converter is arranged in a space 7 between the intermediate wall 6 and the torque converter housing wall 5. 8. The clutch drum 9 that transmits the power input to the input shaft 8 to the transmission mechanism (not shown) disposed between the intermediate wall 6 and the end cover, and the output gear 11 that r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com