Two-stage movable tooth speed reducing transmission device

A transmission device and movable tooth deceleration technology, applied in the direction of gear transmission device, transmission device, belt/chain/gear, etc., can solve the problems of large volume and complex structure, and achieve the effect of small volume, simple overall structure and easy connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

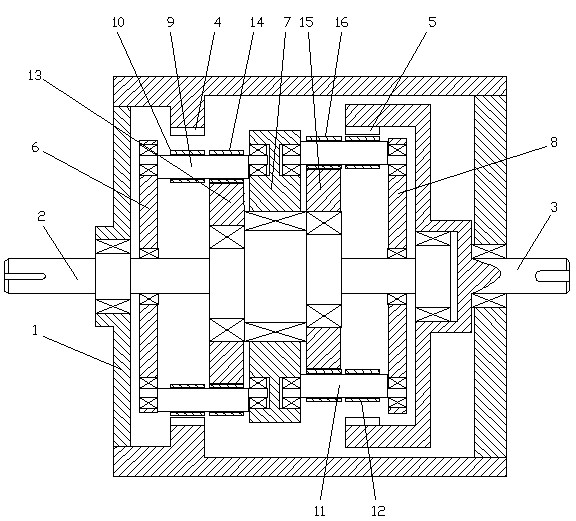

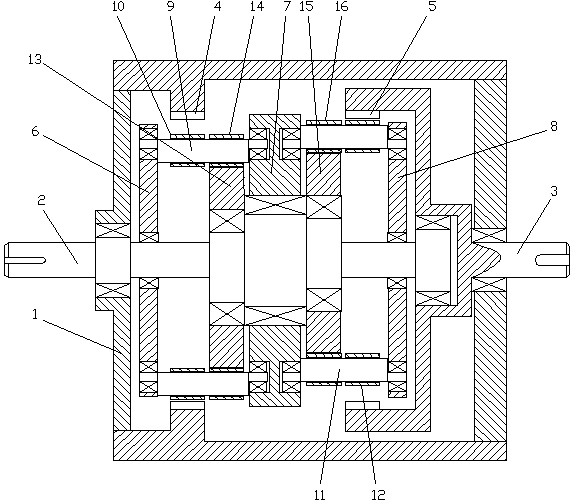

[0013] figure 1 It is a structural schematic diagram of the two-stage movable tooth reduction transmission device of the present invention.

[0014] As shown in the figure, the two-stage movable tooth reduction transmission device in this embodiment includes a housing 1, an eccentric input shaft 2, an output shaft 3, a first-stage internal gear 4, and a second-stage internal gear 5. The upper edge of the eccentric input shaft 2 In its axial direction, the first movable gear frame 6, the primary drive plate, the center plate 7, the secondary drive plate and the second movable gear frame 8 are arranged in sequence in rotation, wherein the primary drive plate and the secondary drive plate are located eccentrically. On the two eccentric shaft sections of the input shaft 2; the eccentric input shaft 2 and the output shaft 3 are arranged on the housing 1 and rotate with it, and the end of the eccentric input shaft 2 is arranged on the output shaft 3 and rotate with it ; The first-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com