Hydraulic drive continuously variable gas inlet system

An air intake system and variable technology, applied in the directions of fuel air intake, engine control, combustion engine, etc., can solve the problems of increasing air intake, large size and weight of the air intake system, and occupying a lot of space, so as to improve the performance of the air intake system. The effect of output power, improving intake efficiency, and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

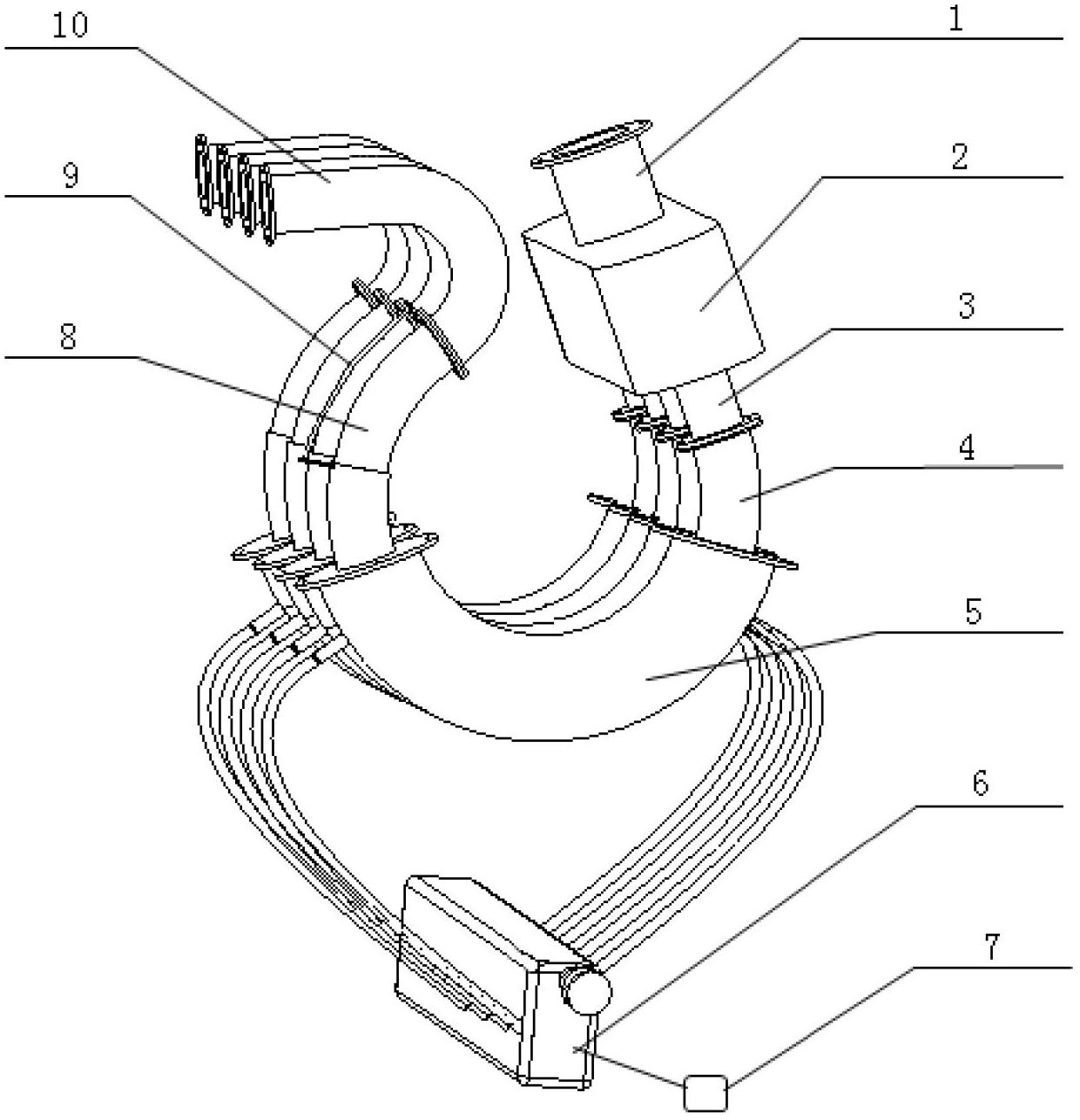

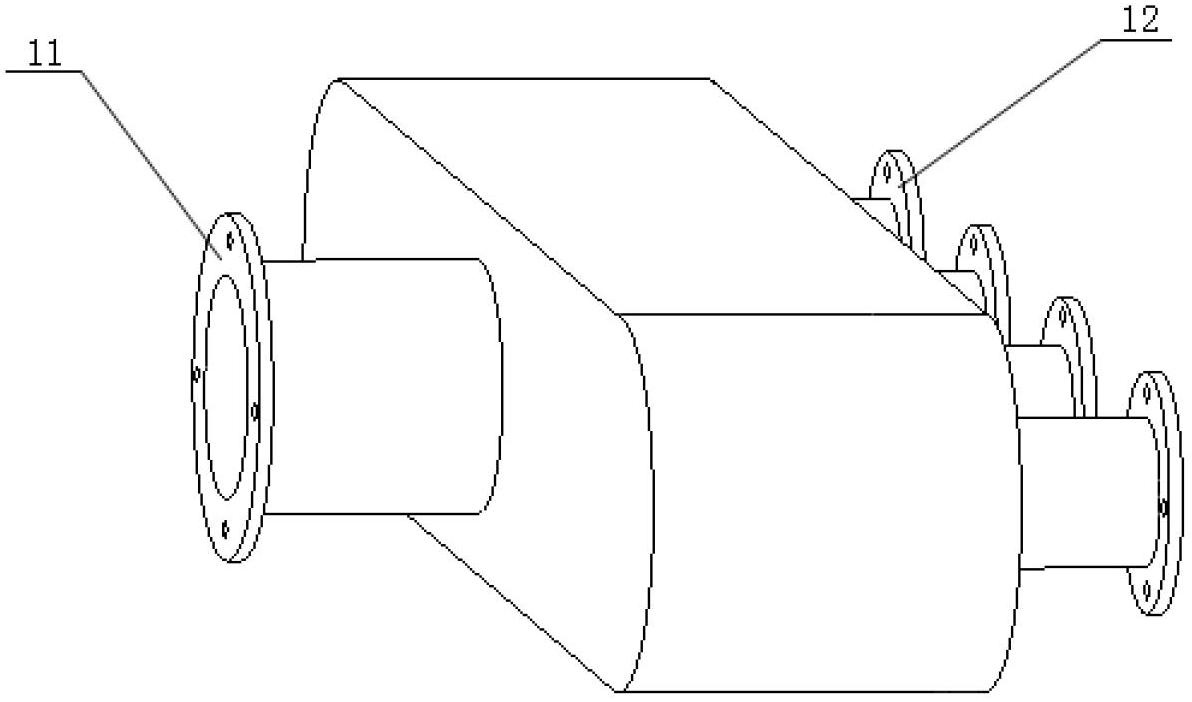

[0022] combine Figure 1-8 , the present invention includes an intake manifold 1, a resonant cavity 2, an intake manifold front section 3, an intake manifold middle outer tube 4, a hydraulic cavity 5, a hydraulic drive unit 6, a hydraulic control unit 7, and an intake manifold middle inner tube 8. The displacement measuring device 9 and the rear section 10 of the intake manifold. It is characterized in that: the front section 3 of the intake manifold, the outer tube 4 in the middle section of the intake manifold, the inner tube 8 in the middle section of the intake manifold and the rear section 10 of the intake manifold together constitute the intake manifold, and the outer tube in the middle section of the intake manifold 4 and the inner tube 8 in the middle section of the intake manifold can move relatively continuously, and the length of the intake manifold ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com