Composition for penetration-driving oil recovery agent and penetration-driving oil recovery agent

A technology of composition and auxiliary agent, which is applied in the field of seepage-displacement oil recovery agent composition and seepage-displacement oil recovery agent, and can solve the problems of low oil recovery and low oil recovery in low-permeability oil reservoirs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of seepage-displacement oil recovery agent

[0039] 0.1g sodium polyacrylate, 0.02gNaHCO 3 and NaCl mixture (NaHCO 3 : NaCl=1:1 (mass ratio)), 0.03g sodium polyaspartate, 0.02g polyoxyethylene sorbitan monooleate, and 99.83g clear water or Daqing formation simulated water are mixed evenly to obtain 100g flooding seepage Type oil recovery agent, the pH value of the seepage displacement type oil recovery agent is 6.8.

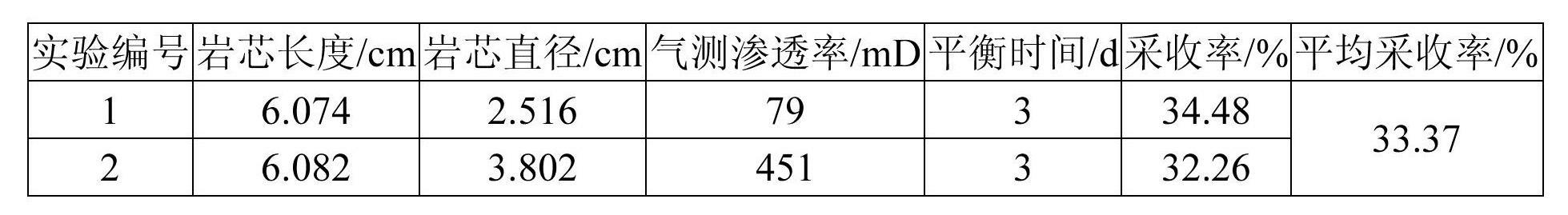

[0040] (2) Imbibition deoiling experiment

[0041] The seepage displacement oil recovery agent prepared by step (1) and the viscosity at 45°C is 10mPa·s, d=0.8294g / cm 3 Static imbibition deoiling experiments were carried out on rock cores saturated with Daqing crude oil. For specific operations, refer to SY / T6424-2000 "Composite Oil Displacement System Performance Test Method" and a normal pressure deoiling bottle (for example: " A self-priming instrument", which is incorporated herein by reference in its entirety). The results are sho...

Embodiment 2

[0045] (1) Preparation of seepage-displacement oil recovery agent

[0046] 0.05g sodium polyacrylate, 0.5gNaHCO 3 and NaCl mixture (NaHCO 3 : NaCl=2:1 (mass ratio)) and 0.05g sodium polyaspartate, and 99.4g clear water or Daqing formation simulated water mix uniformly to obtain 100g seepage-displacement type oil recovery agent, and the pH of the seepage-displacement type oil recovery agent The value is 7.4.

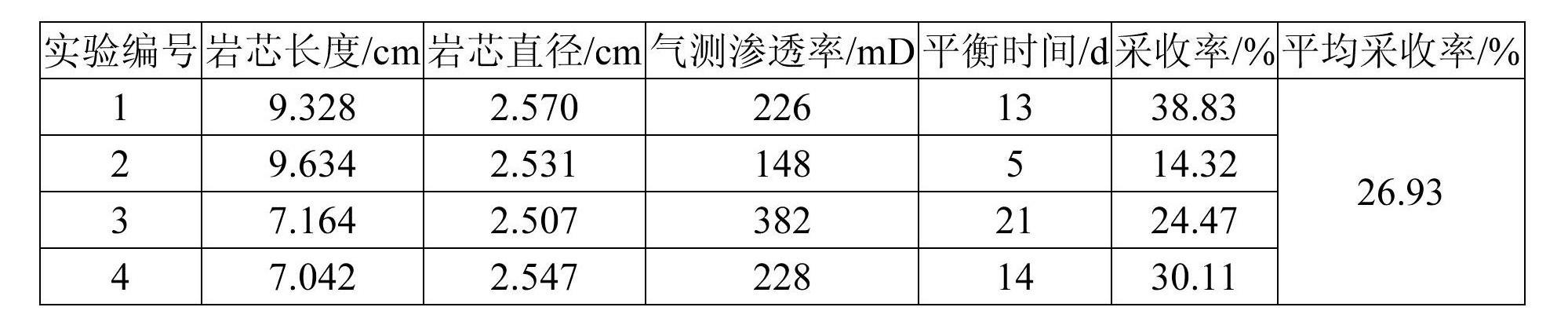

[0047] (2) Imbibition deoiling experiment

[0048] The seepage displacement oil recovery agent prepared by step (1) and the viscosity at 45°C is 10mPa·s, d=0.8294g / cm 3 Static imbibition deoiling experiments were carried out on rock cores saturated with Daqing crude oil. For specific operations, refer to SY / T6424-2000 "Composite Oil Displacement System Performance Test Method" and a normal pressure deoiling bottle (for example: " A self-priming instrument", which is incorporated herein by reference in its entirety). The results are shown in Table 2.

[0049] Table 2...

Embodiment 3

[0052] (1) Preparation of seepage-displacement oil recovery agent

[0053] 0.05g sodium polyacrylate, 0.02gNaHCO 3 and NaCl mixture (NaHCO 3 : NaCl=3:1 (mass ratio)) and 0.01g sodium polyaspartate, and 99.92g clear water or Dagang formation simulated water are mixed uniformly to obtain 100g seepage-dispelling oil recovery agent, and the pH of the seepage-displacement oil recovery agent The value is 6.8.

[0054] (2) Imbibition deoiling experiment

[0055] The seepage displacement oil recovery agent prepared by step (1) and the viscosity at 53°C are 9.9mPa·s, d=0.8603g / cm 3 Static imbibition deoiling experiment was carried out on core crude oil saturated in Dagang. For specific operations, refer to SY / T6424-2000 "Composite Oil Displacement System Performance Test Method" and a normal pressure deoiling bottle (for example: " A self-priming instrument", which is incorporated herein by reference in its entirety). The results are shown in Table 3.

[0056] table 3

[0057] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com