Elevator traction machine of steel wire rope antiskid device

A technology of elevator traction machine and anti-skid device, which is applied to elevators, elevators, transportation and packaging in buildings, etc. It can solve the problems of increasing the friction force of the traction wheel on the wire rope, etc., and achieve the effect of simple and practical working mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

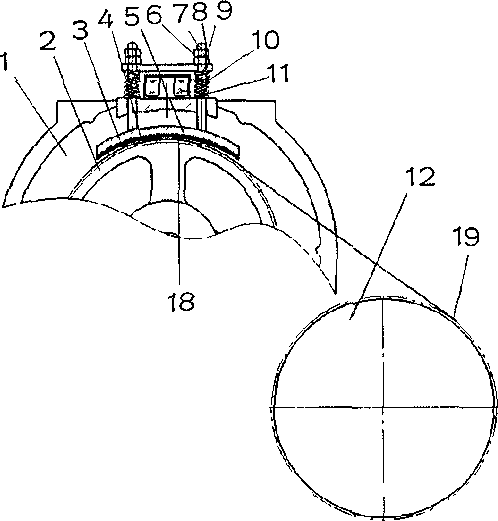

[0022] An elevator traction machine of a steel wire rope anti-skid device of the present invention, such as figure 1 figure 2 , including traction machine main body, brake pad (4), brake shoe (5), column (6), compression plate (7), adjustment nut (8), compression spring (9) or extension spring (16), The electromagnetic brake (10) can be direct suction or inclined block type and elevator related parts, steel wire rope and guide wheel or counterweight wheel.

[0023] Embodiment 1 of the present invention adopts direct-suction braking, sets a sampling point (18) on the guide wheel of the elevator, and sets up a sampling point (19) on the traction machine, when the elevator is running normally, suddenly When a power failure occurs, or the brake of the traction machine works due to a fault, the traction sheave stops or rotates slightly, while the car, wire rope, and guide wheel will continue to work due to inertia, causing the traction sheave and the wire rope to appear. Slippin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com