Air booster pump

An afterburner pump and air technology, applied in the direction of hydraulic brake transmission, etc., can solve the problems of hydraulic cylinder, hydraulic piston corrosion, unreasonable cylinder structure, hydraulic sealing cup damage, etc., to prevent dust pollution, avoid Direct impact, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

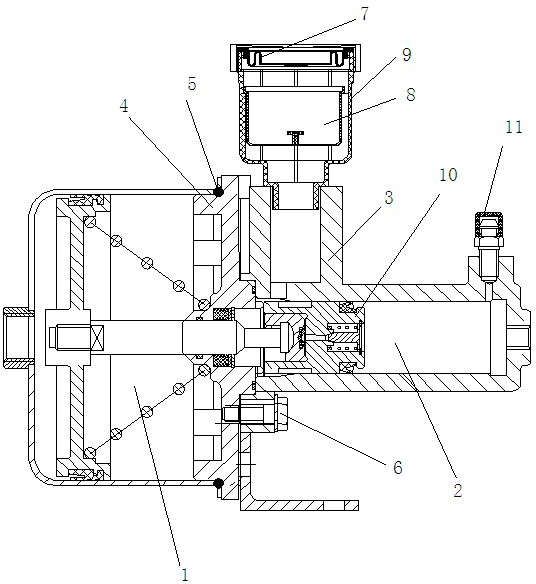

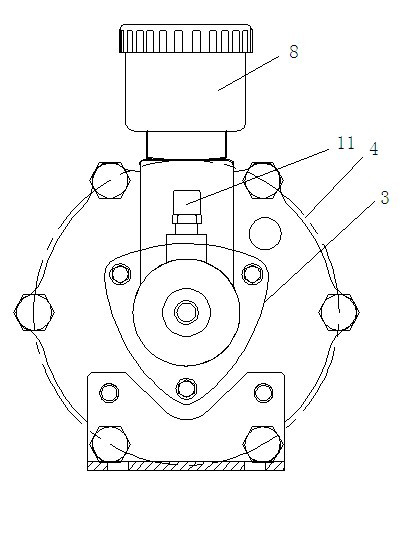

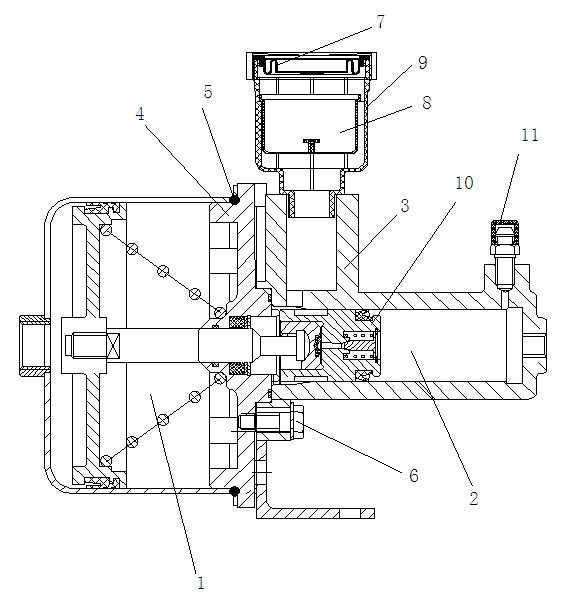

[0019] see figure 1 and 2 , air booster pump, is made up of air chamber cylinder block 4 and hydraulic cylinder block 3.

[0020] A push rod assembly is arranged inside the air chamber cylinder body 4 , and one end of the push rod assembly is connected with the piston 10 in the hydraulic cylinder body 3 .

[0021] The piston 10 is placed in the hydraulic cylinder body 3 , and one end of the piston 10 has a taper. The surface of the piston 10 is provided with an oil injection hole, and the oil injection hole is connected to the oil cup assembly 8 .

[0022] The oil cup assembly 8 is a cylindrical cup body, the inner wall of the oil cup assembly 8 is provided with an air bag sheet 9, and the top cover of the oil cup assembly 8 is provided with an air groove 7 communicating with the air.

[0023] The air chamber cylinder block 4 and the hydraulic cylinder block 3 are connected by bolts 6, and a sealing ring 5 is provided at the contacting part.

[0024] The hydraulic cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com