Aerated concrete block handheld hole processing equipment

A kind of technology of aerated concrete and processing equipment, which is applied in the field of building materials manufacturing, and can solve the problems of increased labor intensity, uneven position of hand-held holes, and ugly appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the content of the present invention easier to understand clearly, the present invention will be described in further detail below according to specific embodiments in conjunction with the accompanying drawings,

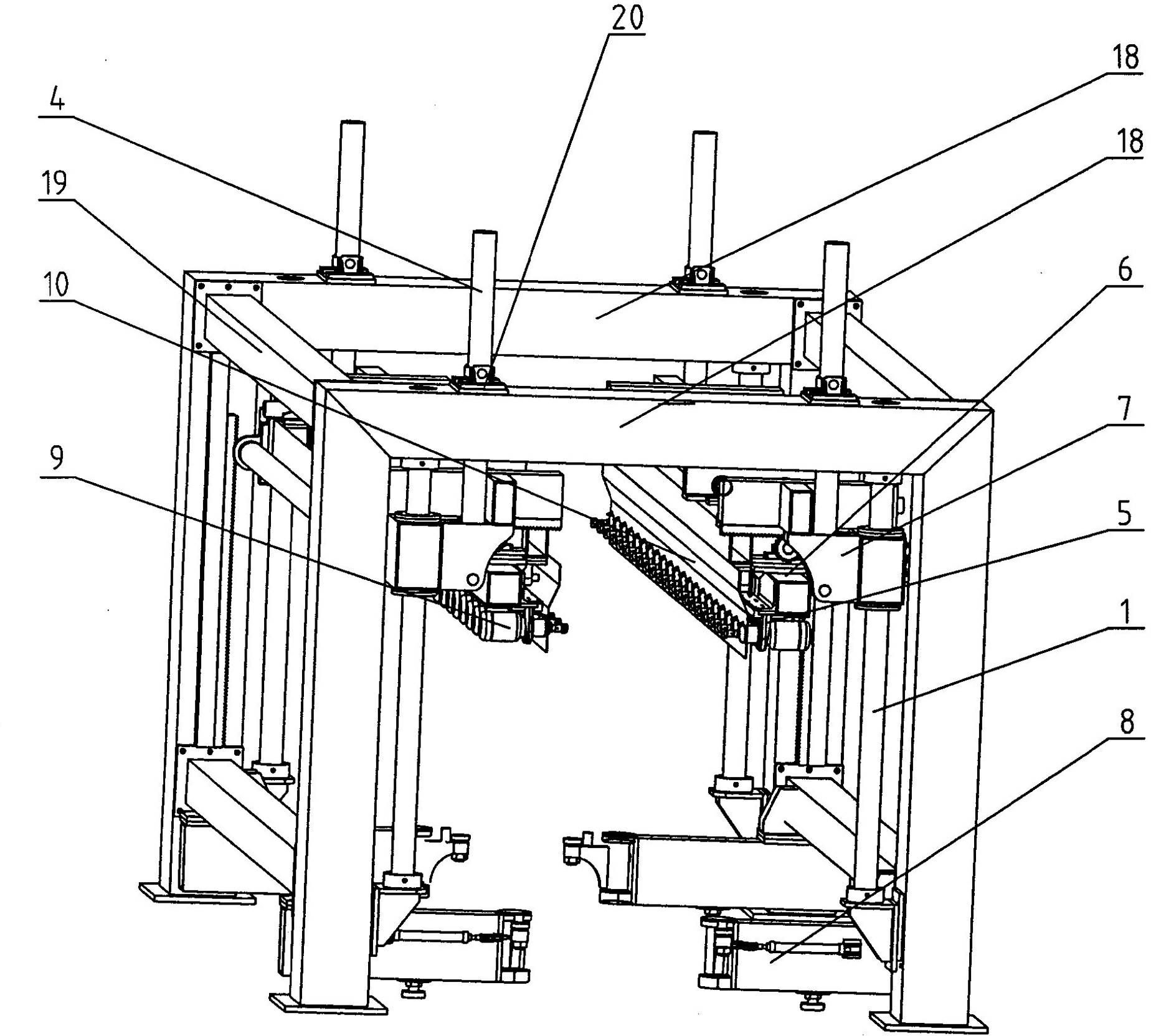

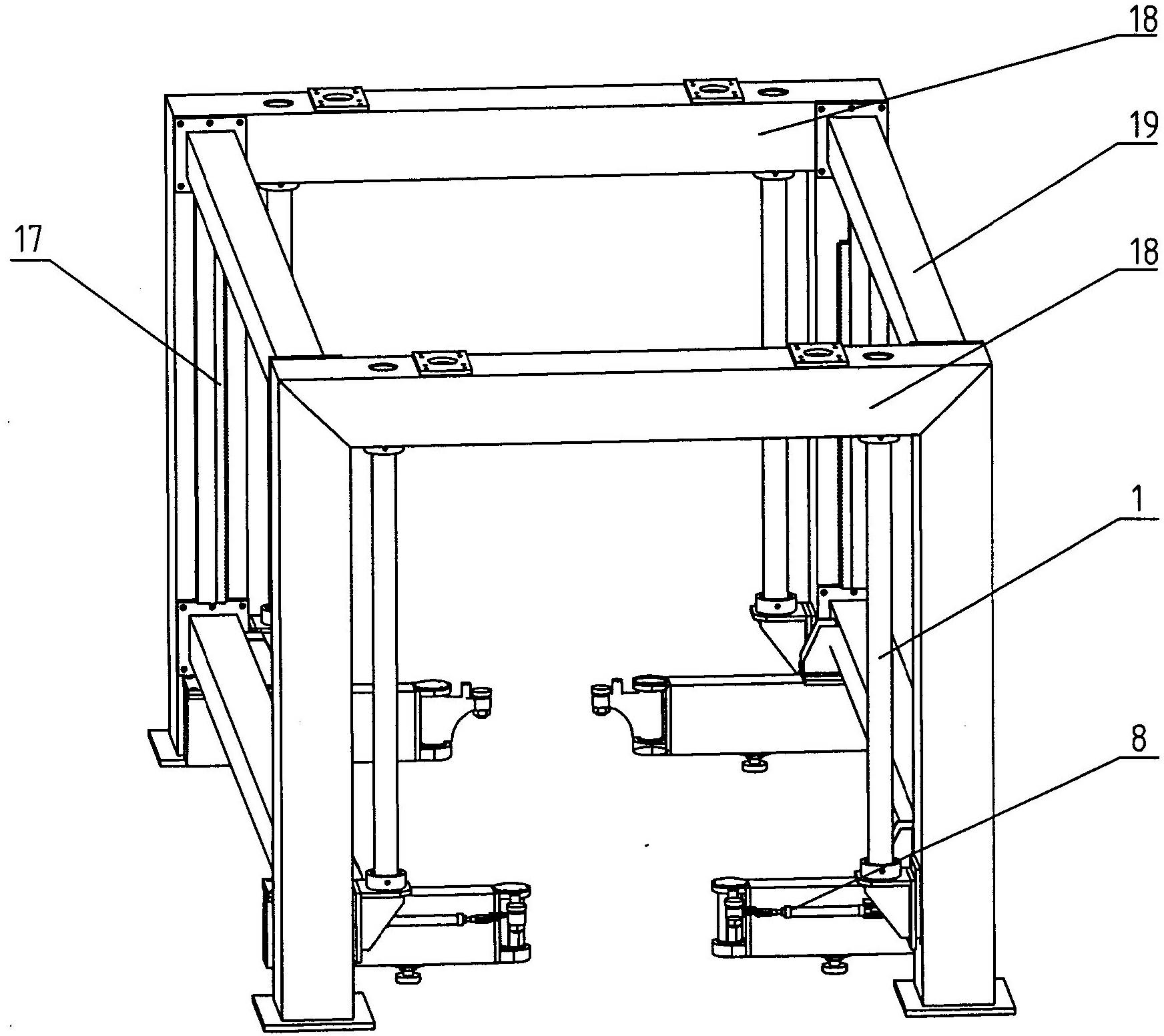

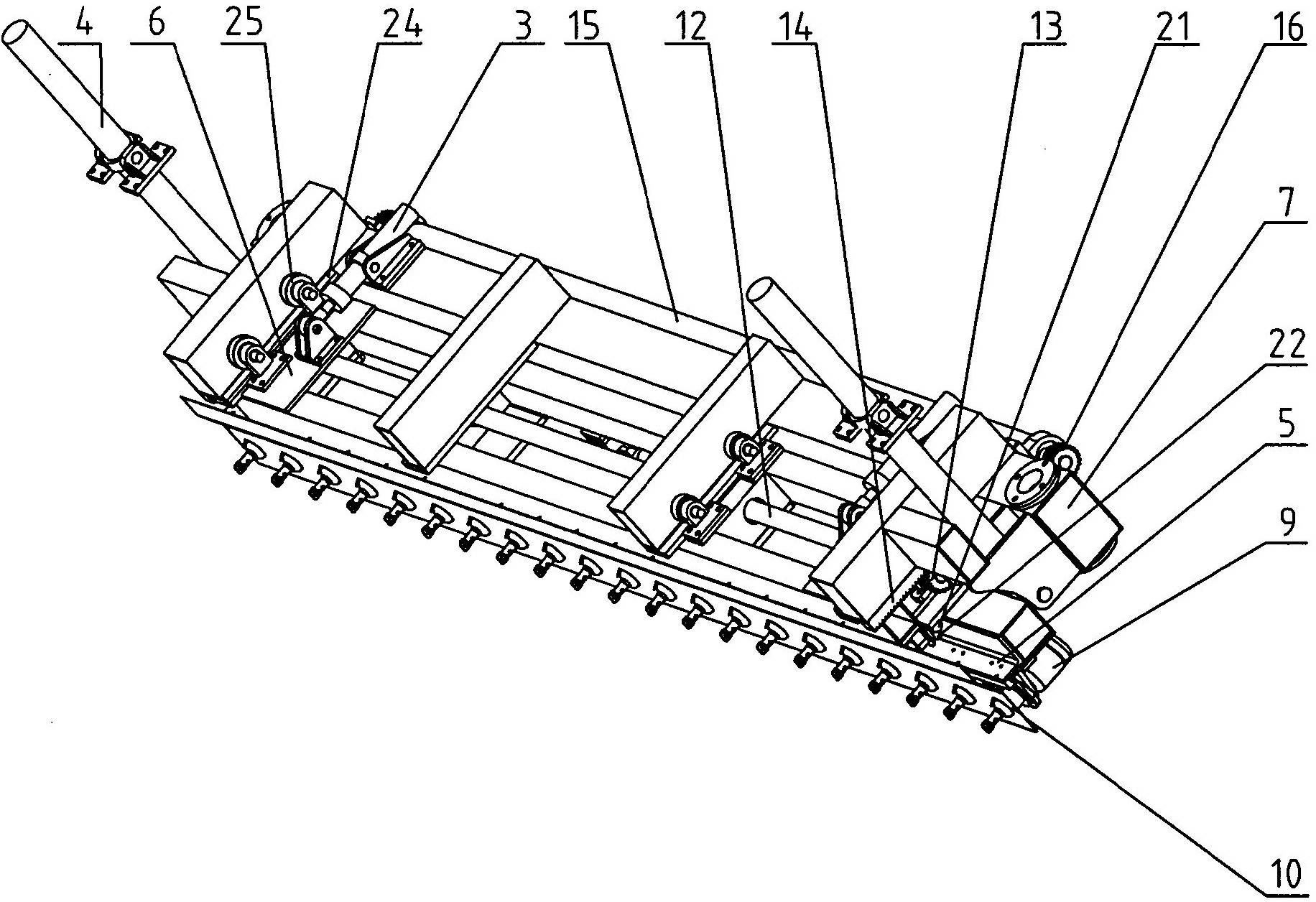

[0020] like Figure 1~7 As shown, a hand-held hole processing equipment for aerated concrete blocks, which includes a main frame and two opposite hole processing devices installed on the main frame, a guide column 1 is fixed on the main frame, and the hole processing device includes a longitudinal movement Oil cylinder 2, horizontal moving oil cylinder 3, up and down moving oil cylinder 4, longitudinal moving device 5, lateral moving device 6 and up and down moving device 7, the lower part of the main frame is equipped with an opening and closing support device 8 supporting the aerated concrete body, and the longitudinal moving oil cylinder The cylinder body of 2 is fixedly connected with the longitudinal moving device 5, the piston rod of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com