Range hood

A technology of range hood and DC motor, applied in the direction of speed/torque control of a single motor, can solve the problems of high energy consumption, low efficiency of AC motor, and high excitation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

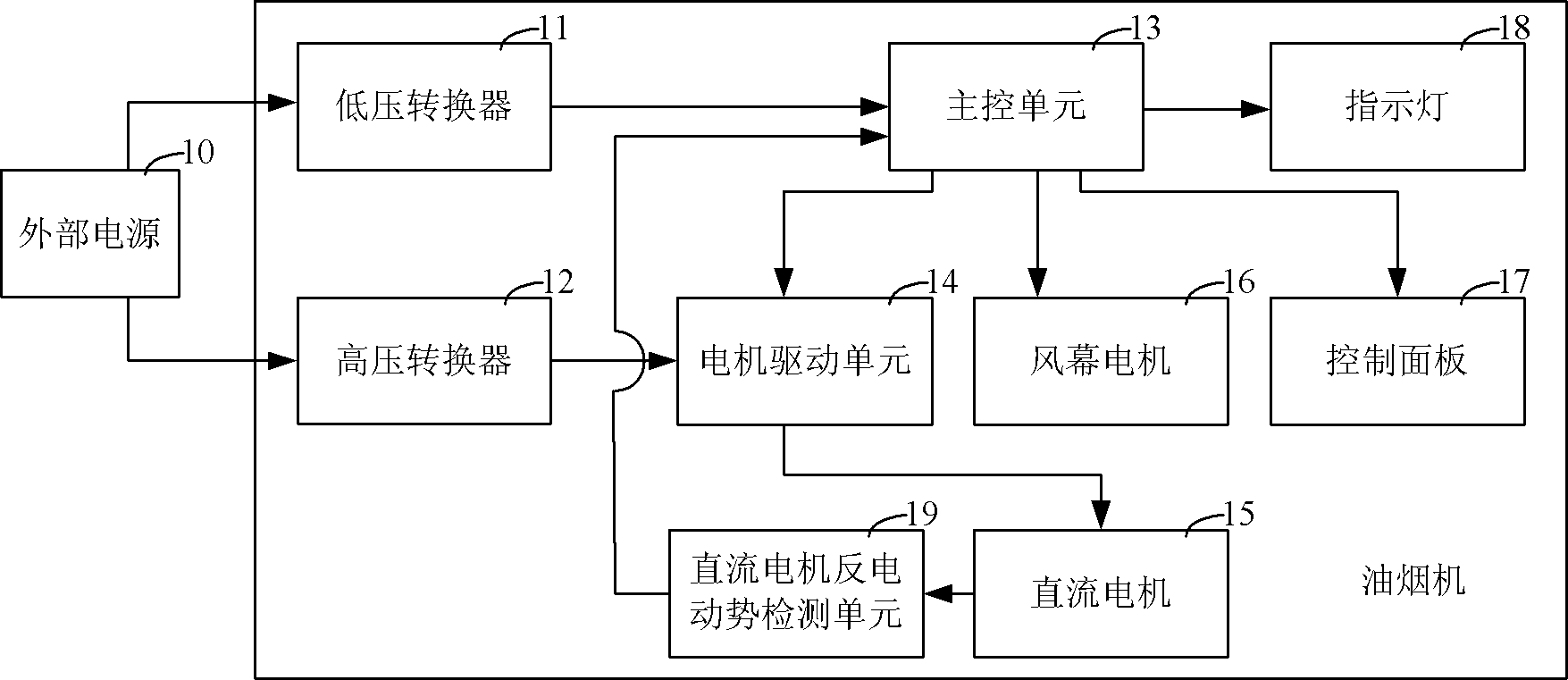

[0020] Attached below Figure 1-5 The range hood of the present invention is described. like figure 1 As shown, the range hood includes a low-voltage converter 11 and a high-voltage converter 12 connected to an external power supply 10; a main control unit 13 connected to the low-voltage converter 11; an air curtain motor 16 connected to the main control unit 13, a control panel 17, The indicator light 18 and the motor drive unit 14, as well as the DC motor 15 connected with the motor drive unit 14.

[0021] The low-voltage converter 11 is used to convert the external 220V voltage into a low voltage for driving the main control unit 13 to work. like Figure 5 As shown, the function of the low-voltage converter 11 is realized by a circuit including an M51995 chip. Wherein, between the M51995 chip and the DSPIC30F3010 chip in the main control unit 13 described later, resistors R1 to R5 are sequentially connected in series, and the resistor R5 is a sampling resistor for colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com