Instruction design method for changing configuration of assembly based on input shaping

A design method and assembly technology, which is applied to the command design when the upper parts of the spacecraft are transposed, and in the field of command design based on input molding assembly change configuration, which can solve the severe vibration of the upper sailboard of the core cabin and the inability to maintain the core cabin. Three-axis stability, no active suppression method for flexible vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

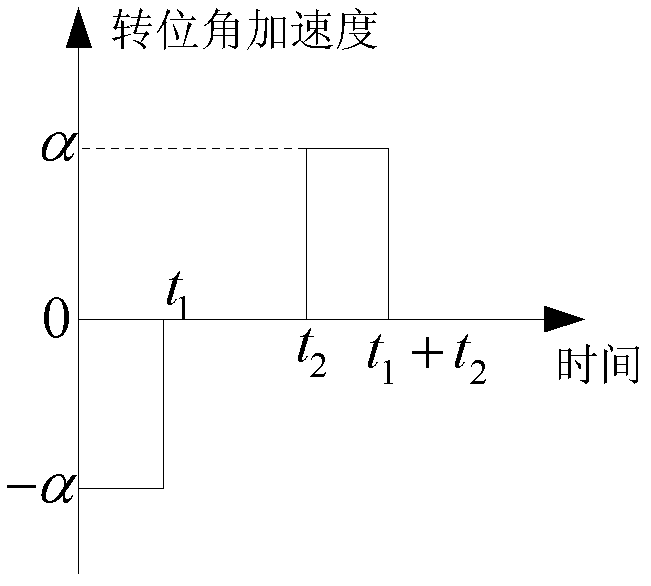

[0035] 1. Design acceleration stage input shaper

[0036] (1) Write down the linearized state equation of the closed-loop system of the composite in the initial configuration

[0037] When the combination is in the configuration before changing the configuration, the linearized closed-loop system state equation is:

[0038]

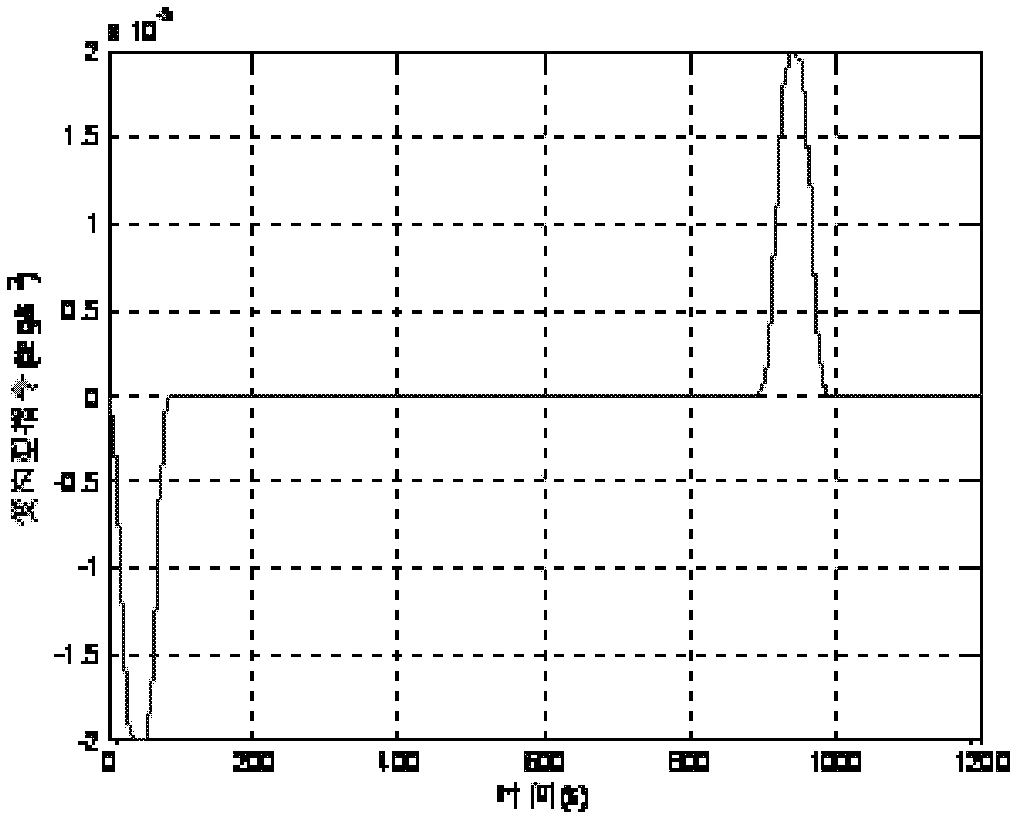

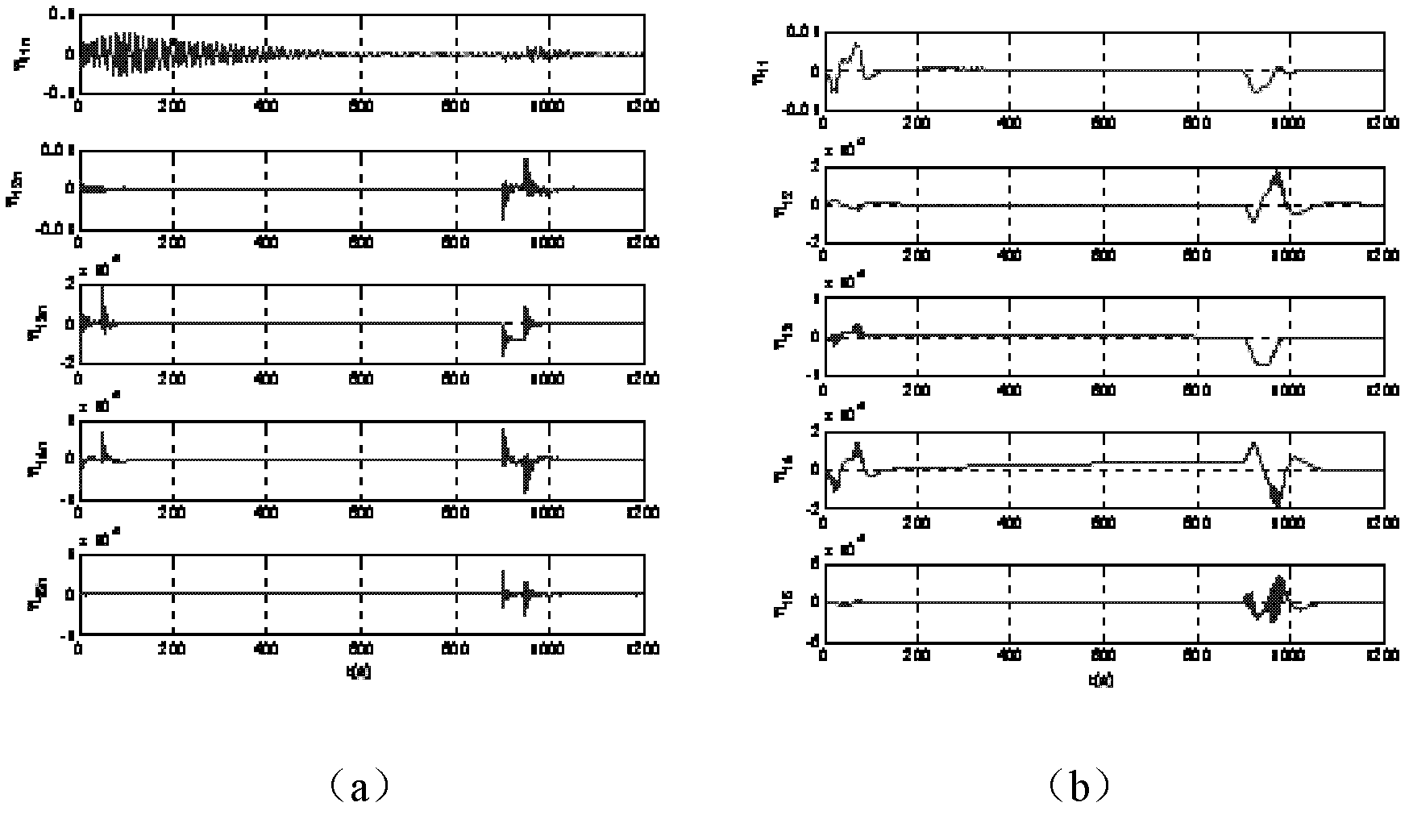

[0039] in m, n ∈ Z + , m is the number of sailboards, n is the highest vibration order to be suppressed by sailboards, and each sailboard is the same; θ and Ψ are the attitude angles of the core module in the roll, pitch and yaw directions respectively; η ij Indicates the jth-order modal coordinates of the i-th sailboard, and x contains m×n modal coordinates in total. K = J F F T E , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com