Electromagnetic acoustic and magnetic leakage compounded detection method

An electromagnetic ultrasonic and composite detection technology, applied in the direction of material magnetic variables, etc., can solve the problem of inability to know the actual shape information of defects, and achieve the effect of fast and convenient measurement, no couplant required, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

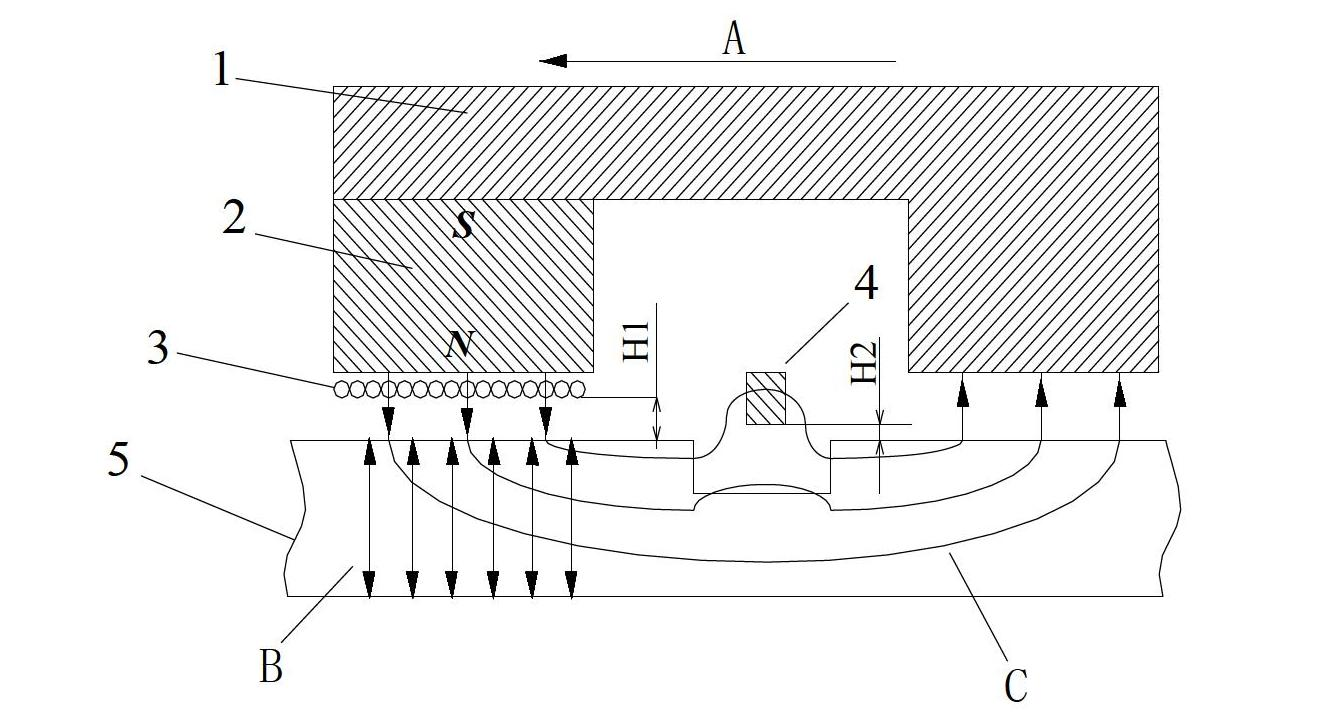

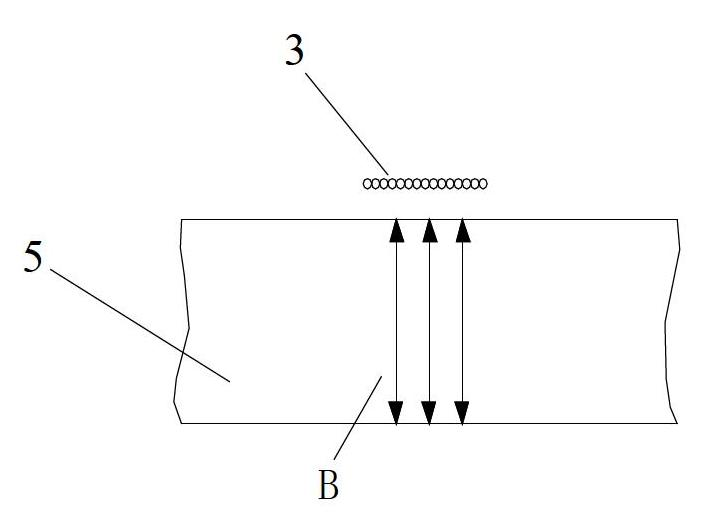

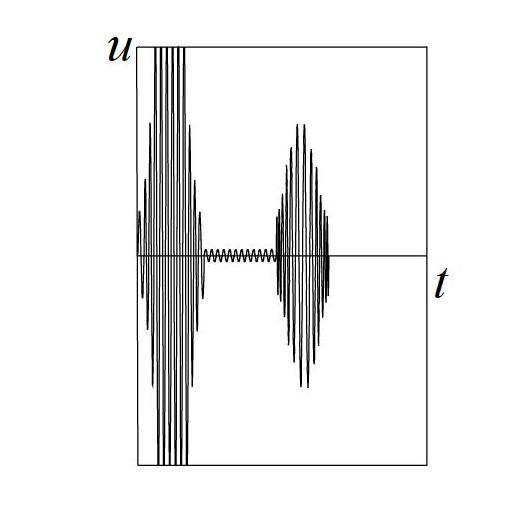

[0037] The Q235 steel plate with a thickness of 8mm is selected as the detection object, and the permanent magnet is N35 NdFeB with a length of 50mm, a width of 30mm, and a thickness of 20mm. The EMAT excitation coil (also used as the EMAT detection coil) is a folded wire coil made of a printed circuit (PCB). The thickness of the PCB is 1mm, and the line width is 0.5mm. Place the probe structure above the steel plate to be tested with a lift-off value of 2 mm, use a Hall element of model AH3503 as the magnetic flux leakage detection element, and measure the magnetic field leakage on the surface of the steel plate with a lift-off value of 1 mm. The steel plate is scanned and detected at a certain detection speed (4m / min). A 1MHz sine wave pulse signal is applied to the EMAT excitation coil during the sampling gap of the magnetic flux leakage detection signal, and the echo signal is detected by the EMAT detection coil. The ultrasonic echo signal detected by the EMAT detection c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com