Dust removing device for filter of automobile

A dust removal device and filter technology, which is applied in the direction of fuel air filter, etc., can solve the problems of affecting the health of operators, flying smoke and dust, polluting the environment, etc., and achieves the advantages of simple structure, reducing environmental pollution, and improving the operating environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

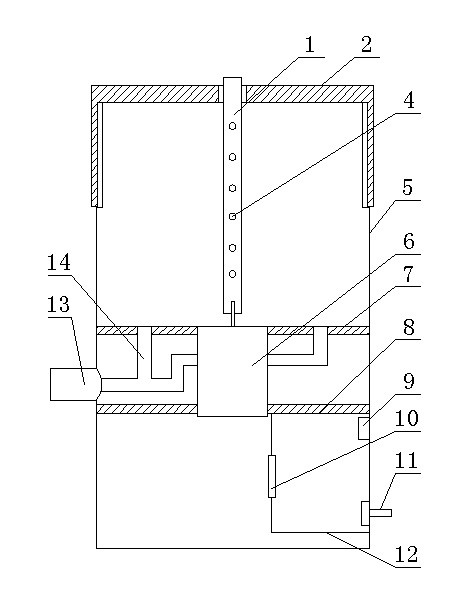

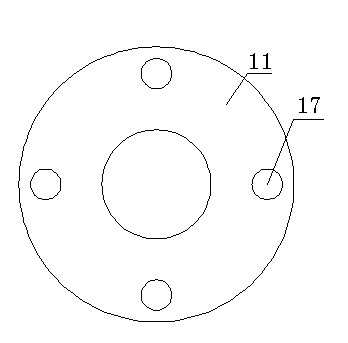

[0018] attached figure 1 Among them, the dust removal mechanism includes a partition 12 arranged on one side below the fixed plate 8, and the partition 12 and the housing 5 form a closed space. An electromagnetic pulse valve 10 is arranged on the partition 12 on one side of the closed space, and a pressure sensor 9 is arranged on the housing 5 on the other side of the closed space, which is connected to the air inlet 11 through a pressure control switch. The partition in this dust removal mechanism is set on one side of the support tube, and its air inlet is connected with compressed air. When in use, after the filter is installed, cover the upper cover, the pressure sensor controls the pressure control switch to open, put in compressed air, when the compressed air reaches a certain value, close the pressure control switch, open the electromagnetic pulse valve, and compress the air Rush out from the electromagnetic pulse valve, quickly enter the filter from the bottom of the ...

Embodiment 2

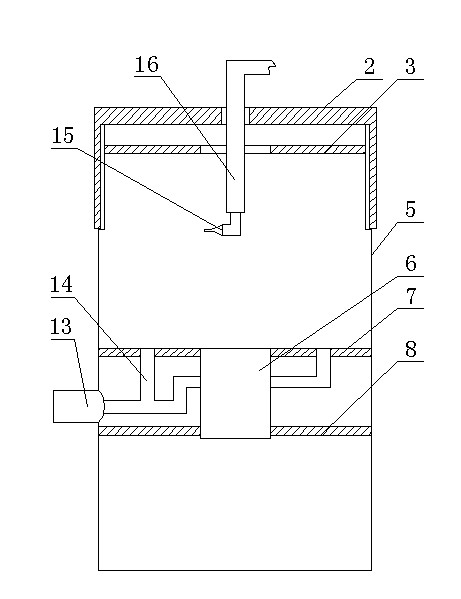

[0021] attached figure 2 Among them, the dust removal mechanism includes a dust-proof plate 3 with a central hole and a compressed gas connecting pipe 16 with a nozzle 15 at the lower end. The compressed gas connecting pipe 16 is flexibly connected with the central hole of the upper cover 2, and the other end of the compressed gas connecting pipe is connected air connection. When in use, install the filter on the support tube, cover the dustproof plate 3, and the dustproof plate 3 is movably connected with the inner wall of the shell 5, that is, the dustproof plate can move up and down with the filter in the shell. Among them, the upper cover is a fully enclosed cover. During the purging process, the upper cover is not covered, only the dustproof plate is covered. Extend the compressed gas connecting pipe into the housing through the center hole of the dust-proof plate, place it in the filter, turn on the compressed air, blow the filter screen from the inside to the outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com