Drum frame supporting power built-in integrated jacking steel platform formwork system and construction method

An integral jacking and steel platform technology, applied in the direction of building structure support, building structure support, formwork/formwork/working frame, etc., can solve the lack of flexibility of steel corbels, affect the safety of high-altitude construction, and lack of targeted measures To avoid the risk of falling objects, improve the level of green construction, and prevent waste leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below with reference to the drawings and embodiments.

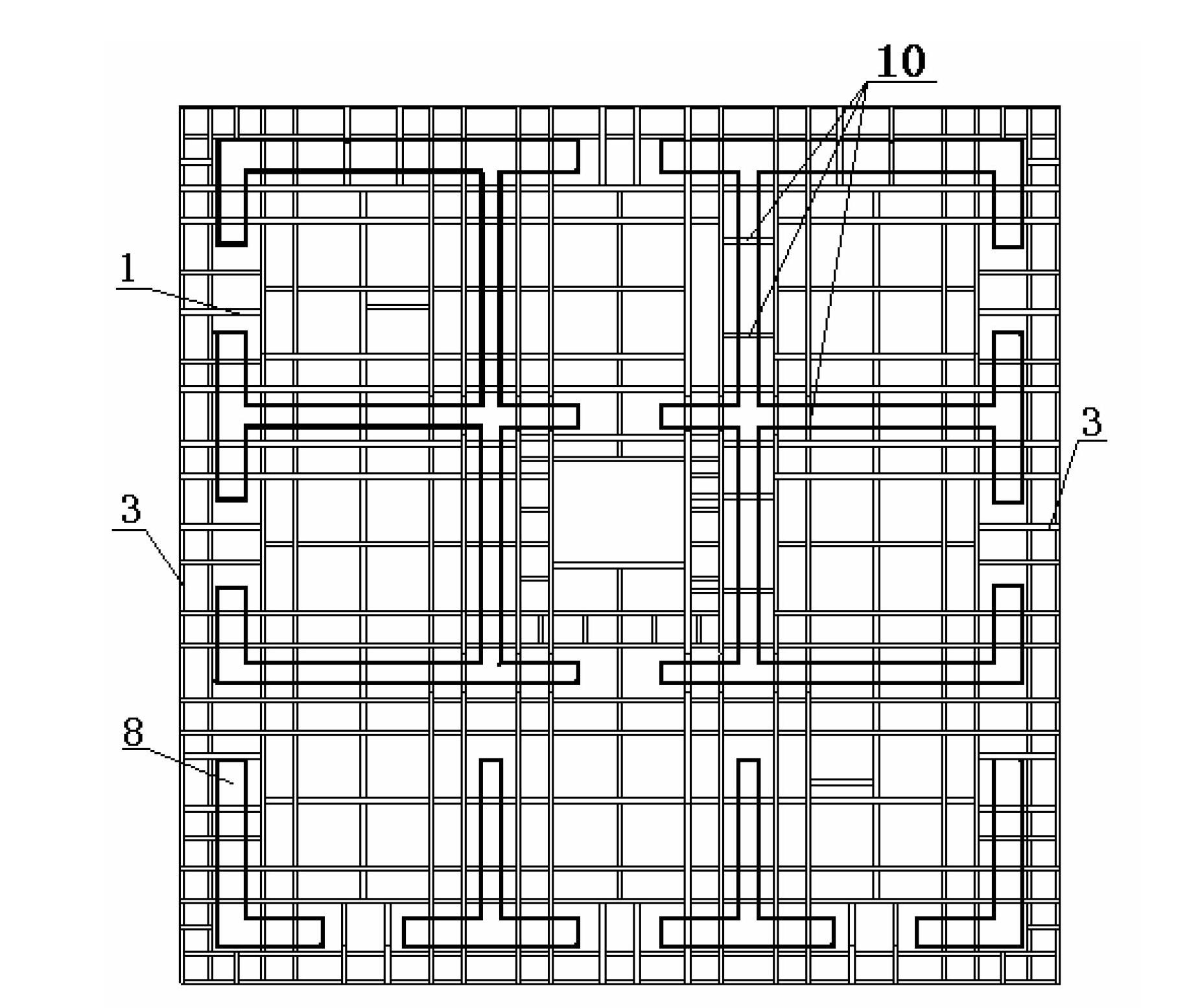

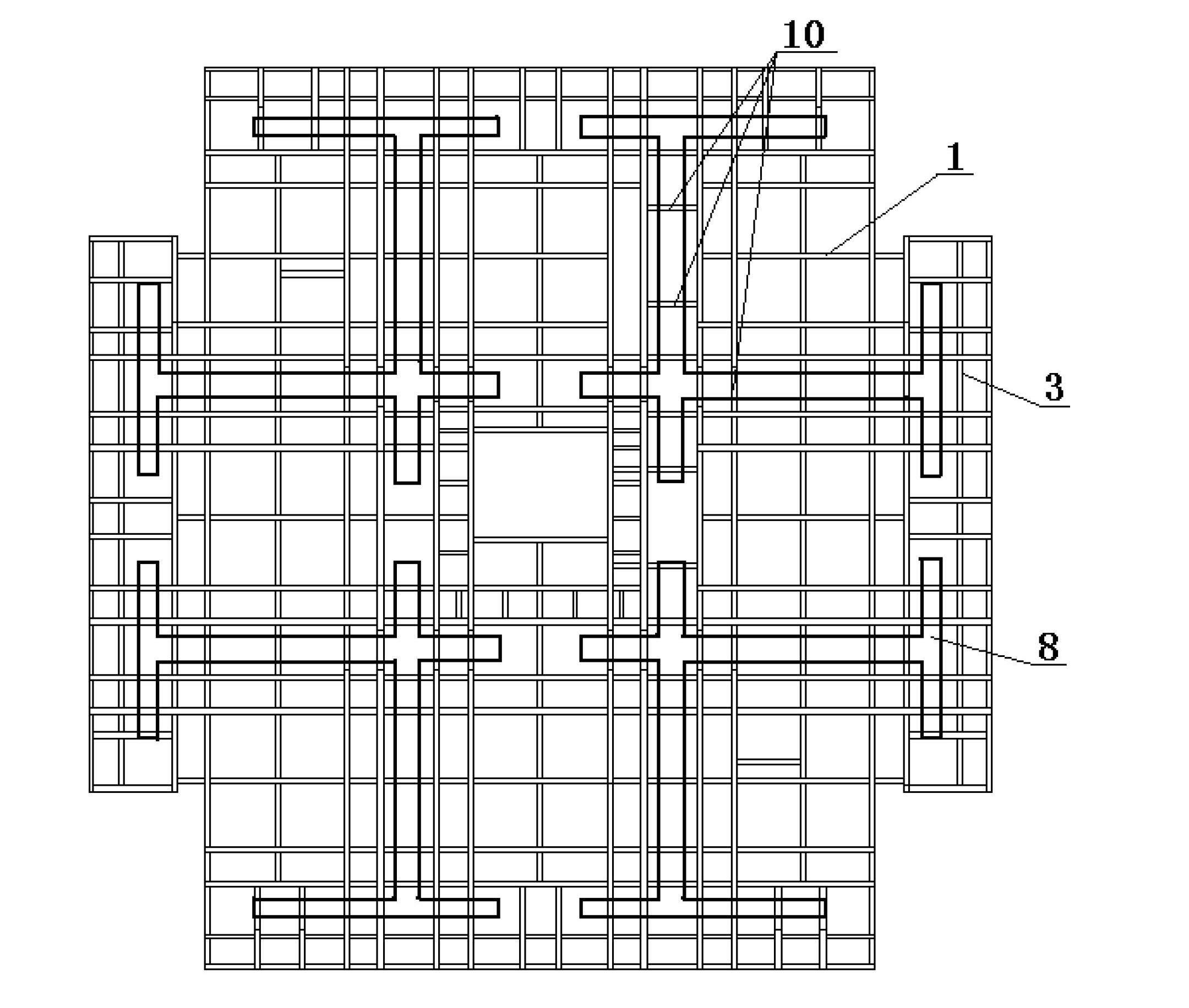

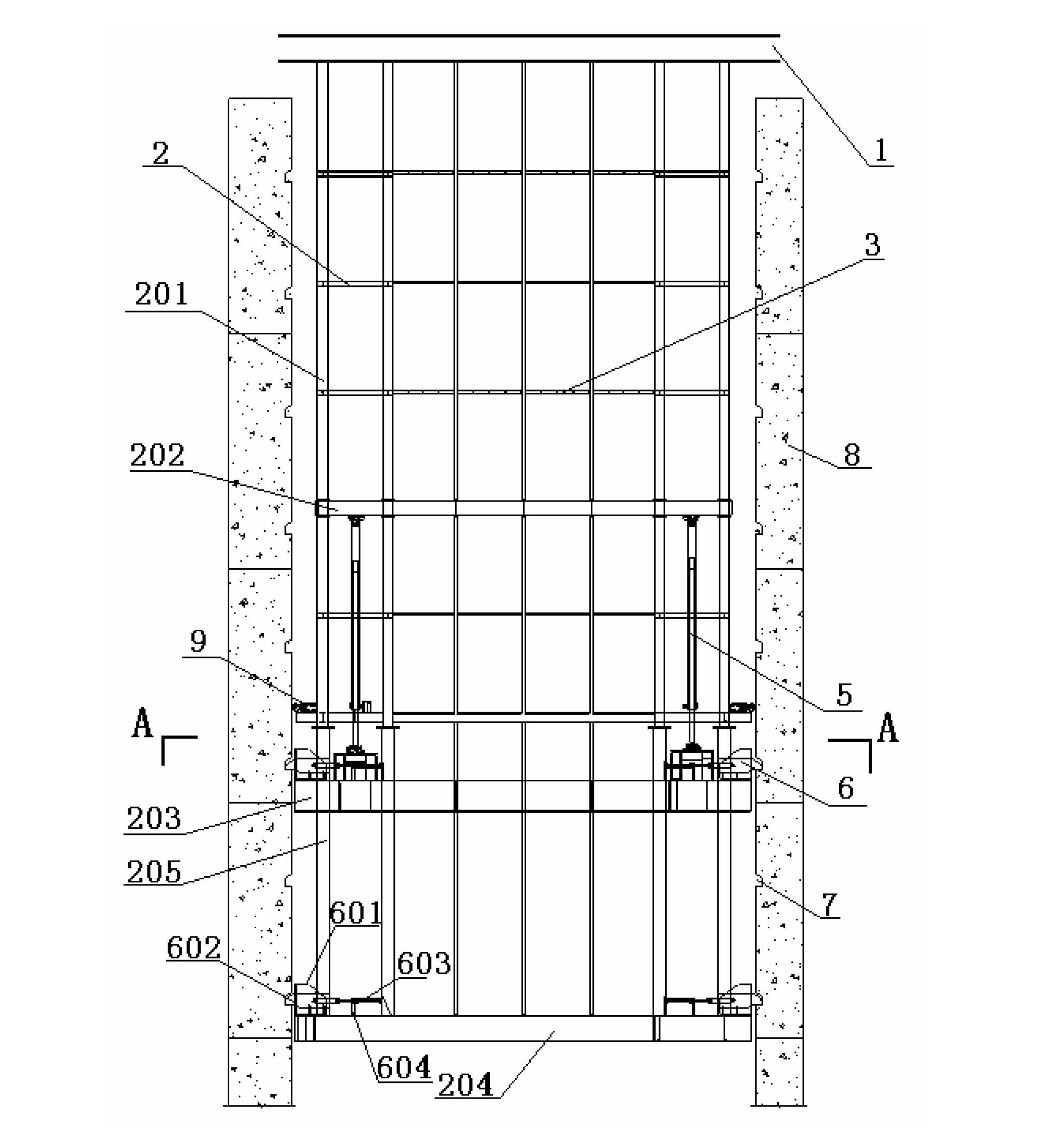

[0038] figure 1 Is a steel platform including several subunits, such as Figure 1~3 As shown, the cylindrical support type power built-in integral jacking steel platform formwork system of the present invention includes a steel platform 1, a support system, a suspended scaffold 3, a formwork system 4, and a hydraulic jacking power system 5. The steel platform 1 is located on the cylinder The suspended scaffold 3 is suspended below the steel platform 1 and is arranged along the core concrete vertical structure 8 and is penetrated and closed; the formwork system 4 is connected by a pair of tension bolts The rear is fixed on both sides of the vertical concrete structure; the support system includes a tube frame support 2 and an inner frame support 203, the tube frame support is fixedly arranged under the steel platform, which in turn includes the steel platform sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com