Palm fruit separation device and method

A separation device and palm fruit technology, applied in threshing equipment, applications, agricultural machinery and tools, etc., can solve the problems of low degree of automation, low production capacity, easy pollution of environmental resources, etc., and achieve automatic production process, continuous production, The effect of reasonable process layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

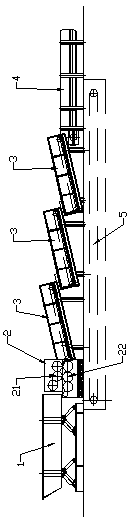

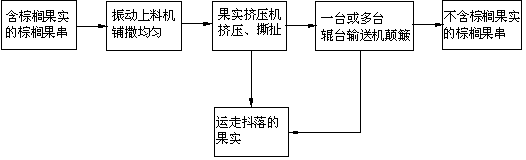

[0012] As shown in the figure, the palm fruit separation device includes a vibrating feeder 1 connected in sequence, a fruit extruder 2, a plurality of roller table conveyors 3 connected in sequence, a fruit bunch belt conveyor 4 and a fruit belt conveyor; The extruder 2 includes a group of upper toothed rollers 21 located at the top and a group of lower toothed rollers 22 located at the bottom, and the fruit bunches with palm fruits pass between the upper and lower toothed rollers to squeeze and separate the fruits; The conveying direction of the roller table conveyor 3 is placed horizontally or obliquely, and the height of the feed end of the latter roller table conveyor is lower than the height of the discharge end of the previous roller table conveyor; The linear speed of the lower toothed rollers varies; the fruit belt conveyor 5 is located below the fruit extruder 2 and the roller table conveyor 3.

[0013] The technical process of the present invention is as follows: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com