Method for extracting natural coenzyme Q10 by using palm residue

An extraction method and palm residue technology, applied in the field of chemistry, can solve the problems of coenzyme Q10 product pollution, the need for complex post-treatment processes, the existence of extraction agents, etc., and achieve the effects of rich functional components, cheap raw materials, and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Dried palm dregs to obtain dried palm dregs; crushed through a 20-mesh sieve

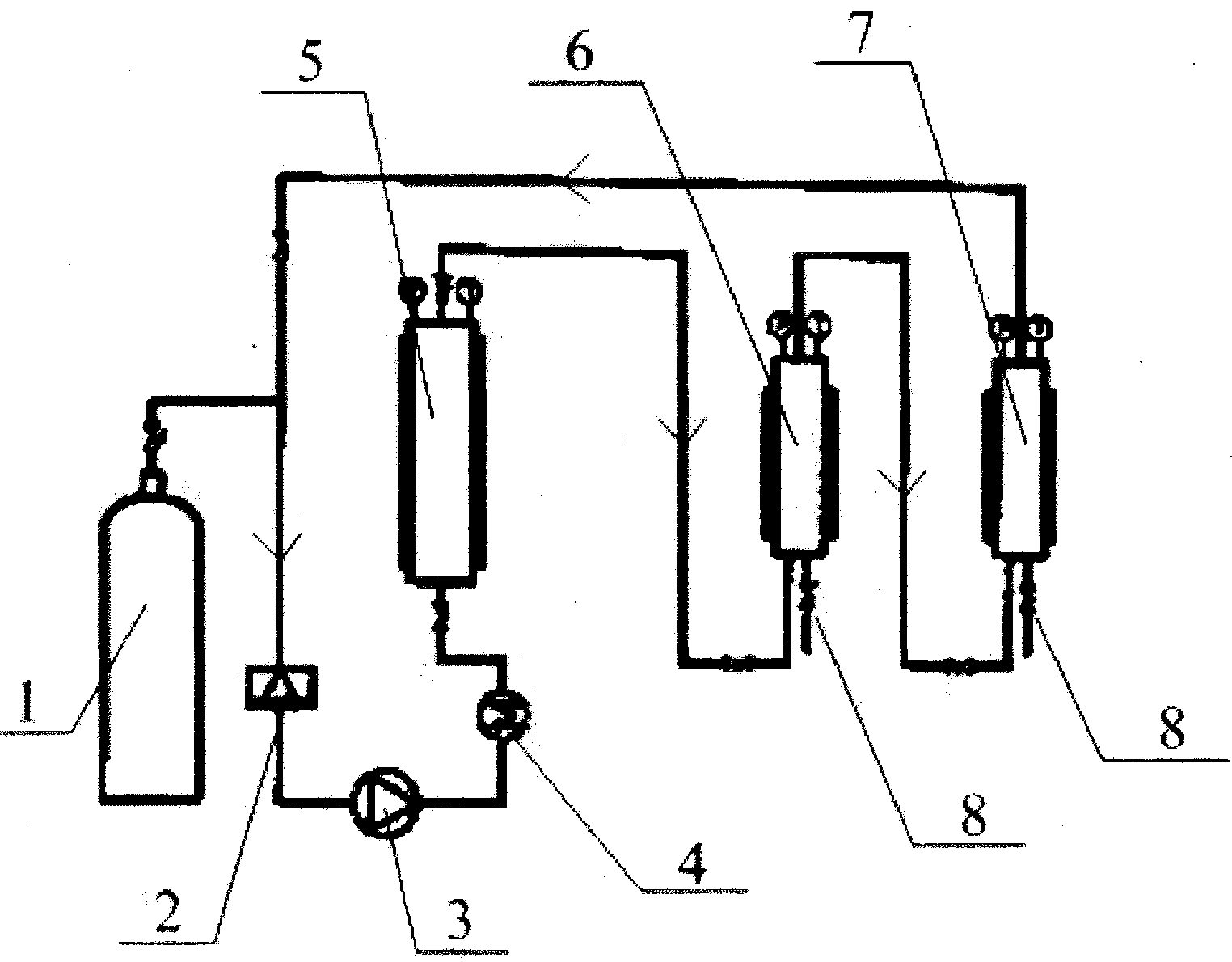

[0046] Add 1000g of the dry and pulverized palm slag in the extraction tank 5, and close the extraction tank; 5, open the gas storage tank 1, and keep the flow rate of carbon dioxide at 480L / h, after the carbon dioxide passes through the condenser 2, the high-pressure pump 3 and the preheater 4 Enter the extraction tank 5, extract under the conditions of 30MPa and 50°C, the extracted carbon dioxide fluid enters the first separator, and perform the first stage separation under the conditions of 10MPa and 45°C to obtain the first coenzyme-rich Oil of Q10: After the first-stage separation, the carbon dioxide fluid continues to enter the second separator, and the second-stage separation is carried out under the conditions of 3MPa and 40°C to obtain the second oil rich in coenzyme Q10.

[0047] After dynamic extraction for 2 hours, a total of 150.9 g of oil rich in coenzyme Q10 was obtained from t...

Embodiment 2

[0049] Palm dregs are dried to obtain dry palm dregs;

[0050] Add the dry palm slag of 1000g in the extraction tank 5, close the extraction tank 5; open the gas storage tank 1, keep the flow of carbon dioxide at 480L / h, and the carbon dioxide enters after the condenser 2, the high pressure pump 3 and the preheater 4 The extraction tank 5 is extracted under the conditions of 25MPa and 50°C, and the extracted carbon dioxide fluid enters the first separator, and the first-stage separation is carried out under the conditions of 9MPa and 50°C to obtain the first coenzyme Q10-rich oil; the carbon dioxide fluid after the first-stage separation continues to enter the second separator, and the second-stage separation is carried out under the conditions of 3MPa and 30°C to obtain the second oil rich in coenzyme Q10.

[0051] After dynamic extraction for 2 hours, a total of 141.88g of oil rich in coenzyme Q10 was obtained from the first separation tank 6 and the second separation tank 7...

Embodiment 3

[0053] Palm dregs are dried to obtain dry palm dregs;

[0054] Add the dry palm slag of 1000g in the extraction tank 5, close the extraction tank 5; open the gas storage tank 1, and keep the flow of carbon dioxide at 480L / h, and the carbon dioxide enters the place after the condenser 2, the high-pressure pump 3 and the preheater 4 The extraction tank 5 described above is extracted under the conditions of 18MPa and 45°C, and the extracted carbon dioxide fluid enters the first separator, and the first-stage separation is carried out under the conditions of 8MPa and 45°C to obtain the first coenzyme Q10-rich Oil: After the first stage separation, the carbon dioxide fluid continues to enter the second separator, and the second stage separation is carried out under the conditions of 3MPa and 30°C to obtain the second oil rich in coenzyme Q10.

[0055] After dynamic extraction for 2 hours, a total of 121.3g of oil rich in coenzyme Q10 was obtained from the first separation tank 6 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com