Collet chuck

A chuck chuck and chuck technology, which is applied to chucks, accessories of tool holders, pipes/pipe joints/pipes, etc., can solve the problems of expensive production and assembly, complex structure of chuck chucks, etc., and achieve uniformity. Force action, the effect of promoting alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

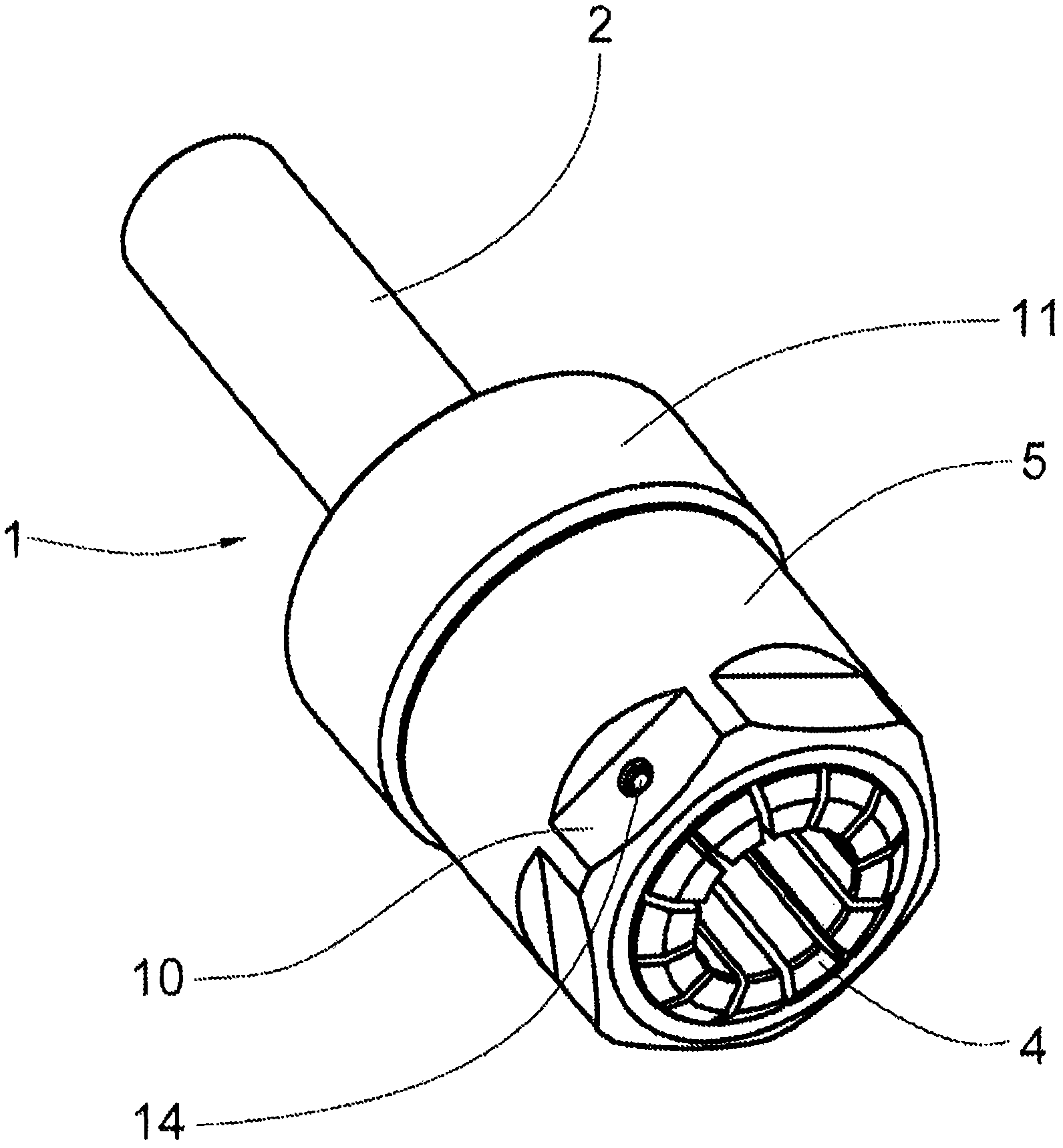

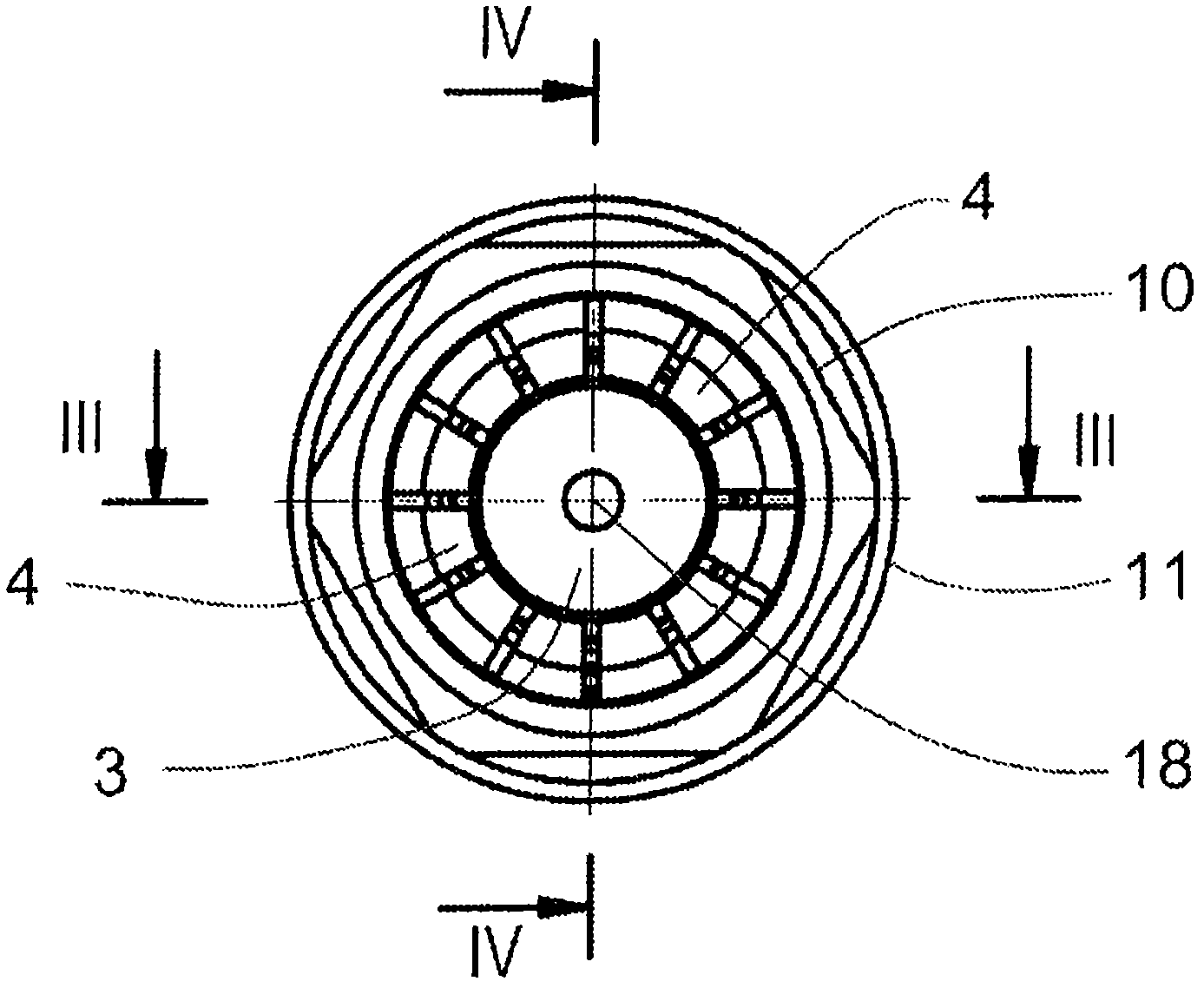

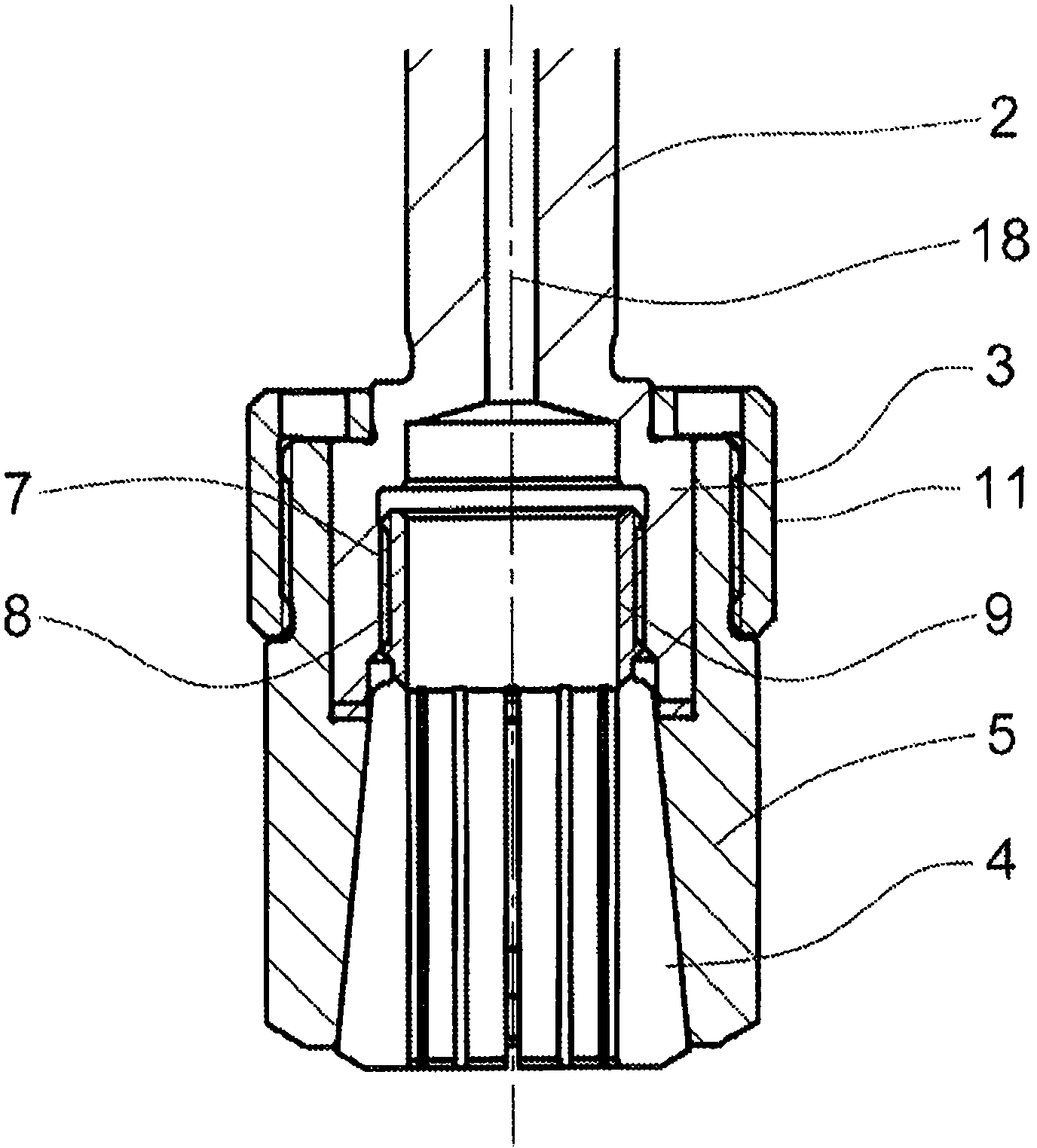

[0032] in the attached Figure 1 to Figure 15 Shown in the collet chuck 1, what is common to them is that it has a chuck body 3 connected or connectable to the drive shaft 2 in a rotationally fixed manner, a collet 4 and a cone associated with the chuck body 3 shaped sleeve 5. The conical sleeve 5 itself is arranged axially immovably on the chuck body 3 . In addition, a threaded connection 6 is effective between the chuck body 3 and the collet 4, so that when the axis of the workpiece or tool (for example an upper milling cutter) is clamped, the basic clamping is achieved by the rotation of the chuck body 3 (Grundspannung ). In operation of the collet chuck 1, a braking torque acts on the tool, which is a torque opposite to the direction of rotation of the drive shaft 2, so that a rotation of the collet 4 relative to the chuck body 3 is achieved, which due to The formed screw connection 6 brings about an axial displacement of the collet 4 . This axial movement of the colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com