Detecting and monitoring method and measuring system for dynamic axis and bending of rotary kiln tube

A technology of dynamic detection and rotary kiln, which is applied in the direction of measuring devices and instruments, can solve the problems of cumbersome and time-consuming, complicated operation, safety hazards, etc., and achieve the effect of simplifying the measurement link and process, measuring operation safety and shortening the measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail below with reference to accompanying drawing and specific embodiment:

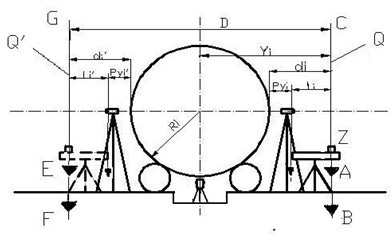

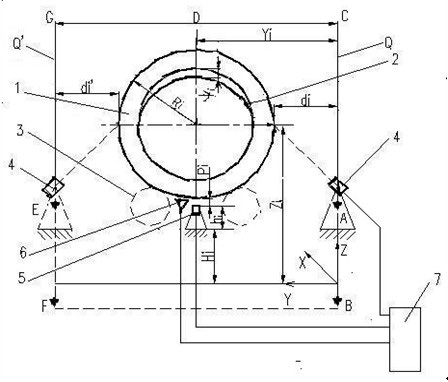

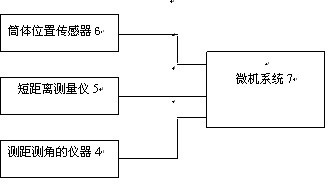

[0040] figure 1 , has been introduced in the background technology, and is omitted here. See image 3 The method of the present invention is as follows: first, a rectangular coordinate system X, Y, Z is established outside the rotary kiln, and the X axis is substantially parallel to the axis of the rotary kiln shell. See figure 2 , and parallel to the X axis, two pairs of targets are fixed at four points A, B, E, and F away from the two sides of the kiln base pier. Based on this, two pairs of targets with a distance of D and parallel to each other are established with a theodolite (A, B, and C are determined ) vertical plane Q and (determination of E, F, G) vertical plane Q′.

[0041] (1) Determine the average abscissa Y i

[0042] At X=X perpendicular to the X axis i Each measuring point X on the ground or other structures where the section in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com