Overhead roof production system and overhead roof pavement method

A technology of production system and electric control system, which is applied in roofing, tools for roofing engineering, construction, etc., can solve the problems that affect the quality of roofing forming and laying efficiency, the roof steel plates cannot be bonded, and it is difficult to adapt to complex roofing construction requirements. Achieve the effect of improving molding quality and laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

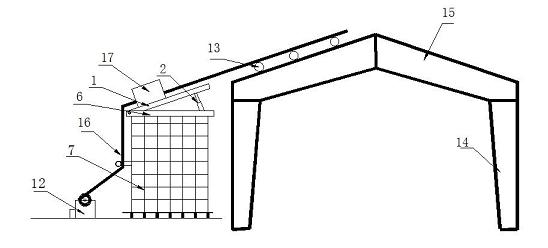

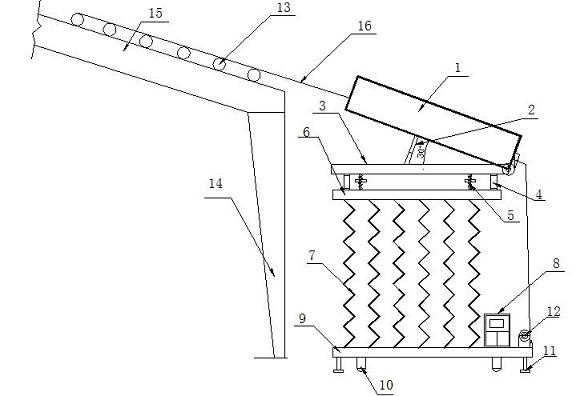

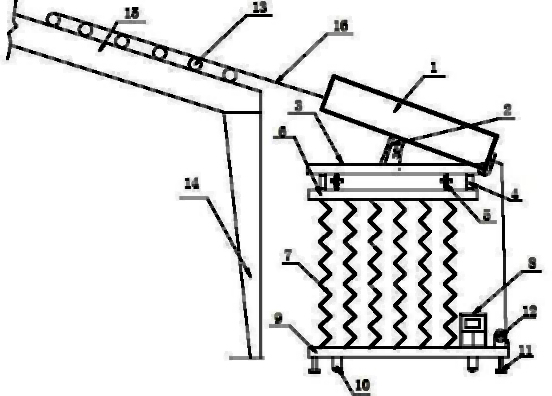

[0047] figure 1 Shown is the high-altitude roof production system of the present invention, including a support frame 7 placed horizontally; a support top plate 6 fixedly placed on the support frame 7; a machine platform 1 fixedly placed on the support top plate 6; Forming machine 17 in described machine platform 1; And be arranged on the steel plate coil rack 12 on the ground; Also be provided with organic platform base 3 between described machine platform 1 and described support top plate 6, described machine platform base 3 Hinged with the spliced end of the machine table, the free end of the machine table can rotate around the hinged end, and a telescopic booster device 2 is arranged between the base 3 of the machine table and the machine table 1 and close to the free end of the machine table . In this embodiment, the support frame 7 is an ordinary non-telescopic support frame, and the free end of the machine table can rotate around the hinged end in an angle range of 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com