Five-grain wine brewing method and special device thereof

A special equipment and technology of rice liquor, applied in the field of five rice liquor brewing method and special equipment field, can solve the problems of low liquor production rate, harm to human health, less beneficial substances, etc. Harmful substances, long aftertaste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Selection of raw materials: select high-quality five meters and 100 kilograms, mixed in the proportion of 60 kilograms of sorghum rice, 10 kilograms of rice, 10 kilograms of millet, and 10 kilograms of millet and 10 kilograms of wheat kernels.

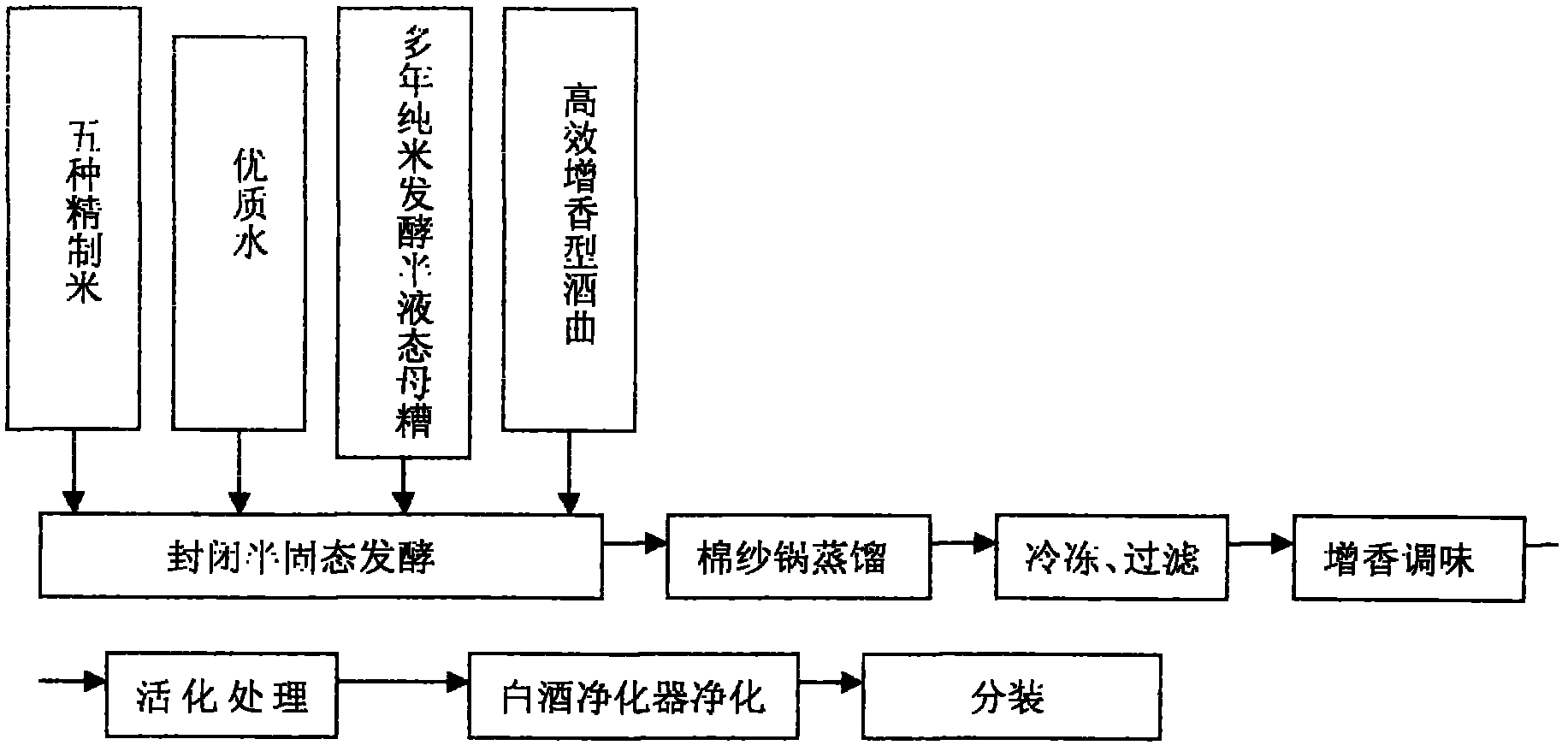

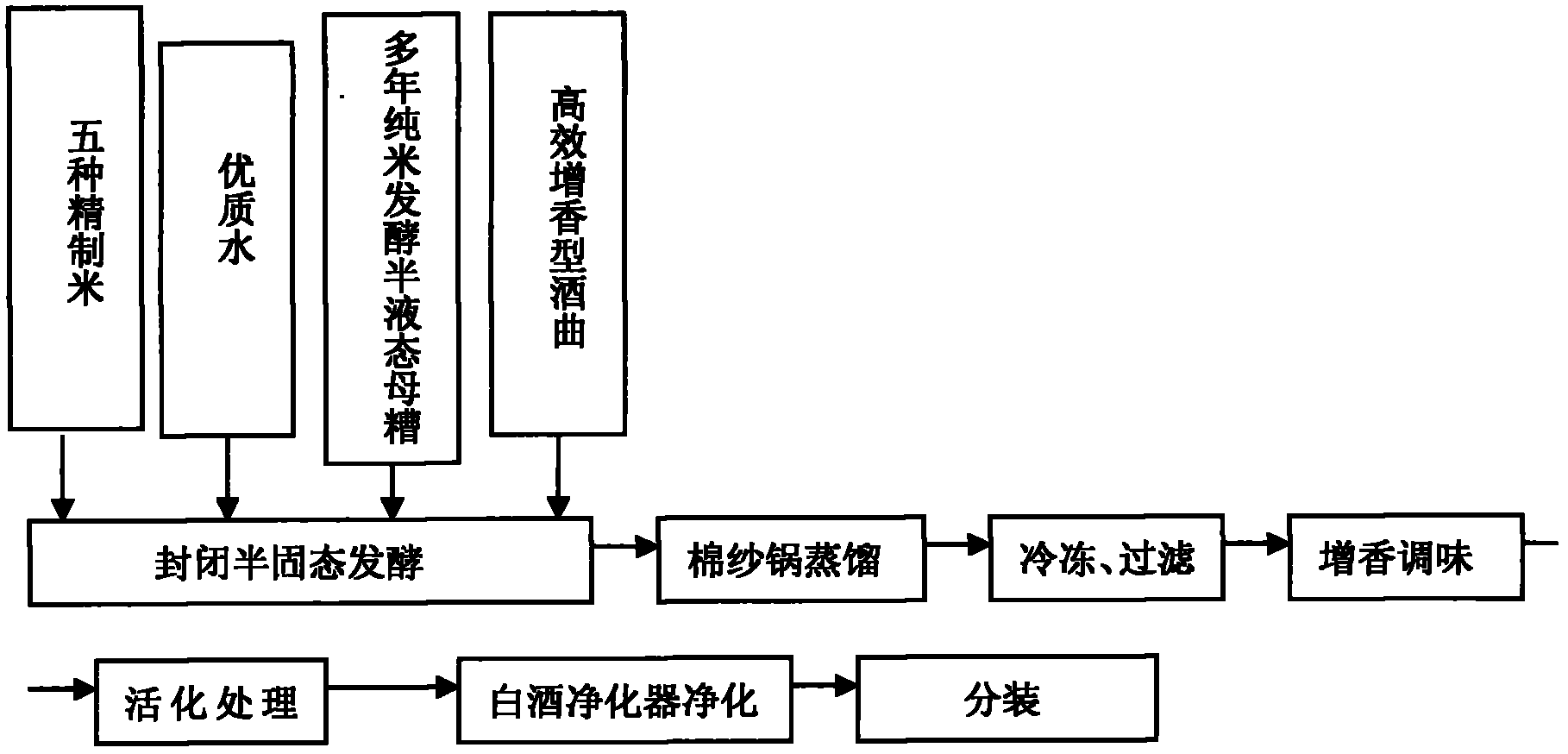

[0022] Semi-solid fermentation: Put 100 kg of raw materials, 120 kg of semi-liquid mother grains of pure rice fermentation for many years, 0.7 kg of high-efficiency flavor-enhancing koji, and 200 kg of high-quality 1.5dh raw water into the container and stir once, and the fermentation shall be sealed at room temperature above 20℃. , Stir every 4 days and ferment for 1 year.

[0023] Cotton gauze pot distillation: in the container, first pour 20% of the container's clean water, and then place a stand, place a breathable plate on the stand, place a basket with cotton gauze tube, cover the pot, boil it on high fire, and after the water is boiled, Put the fermented semi-solid fermented mash on the cage, the wine steam is blown into the c...

Embodiment 2

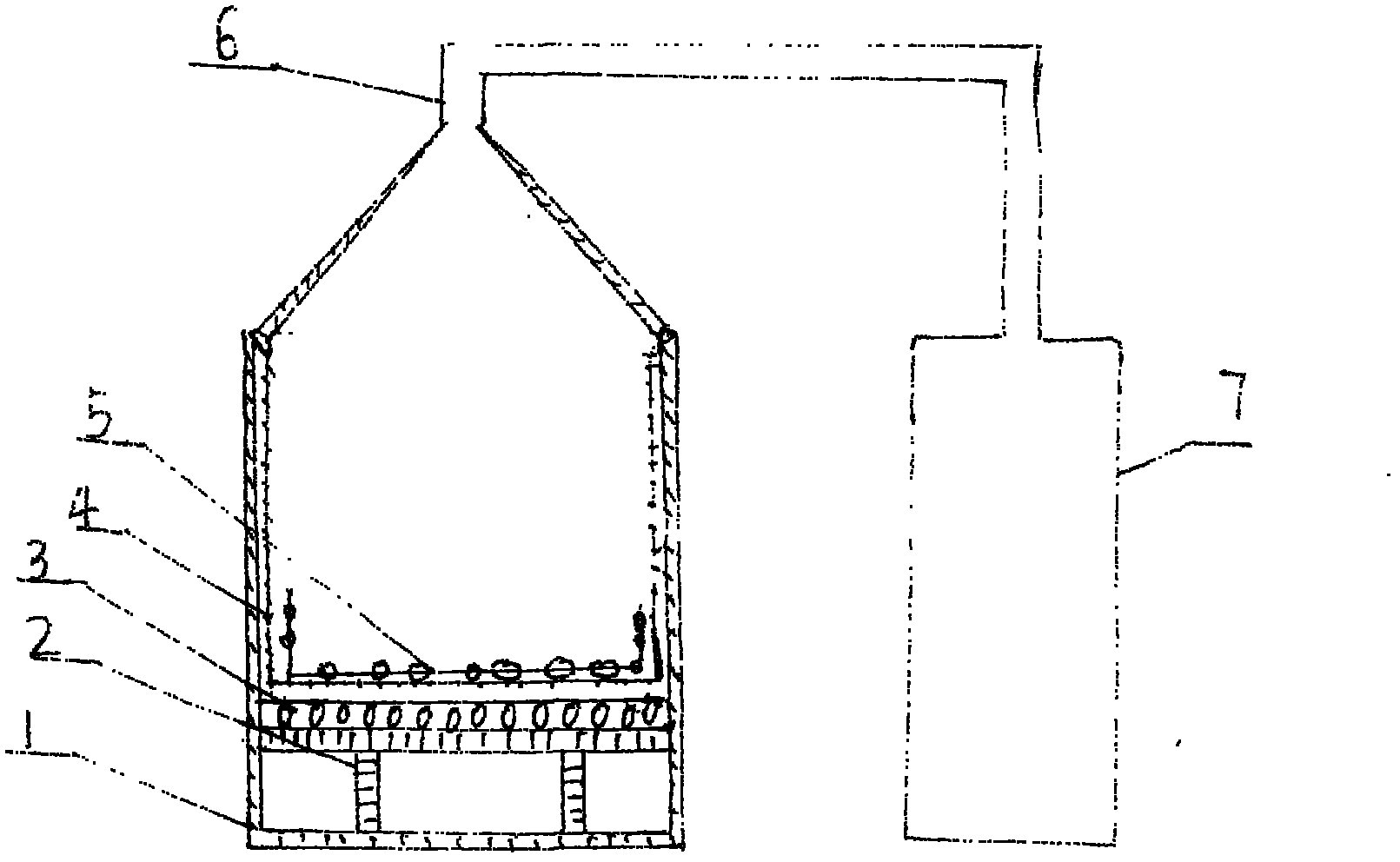

[0027] The structure diagram of the special equipment used in the present invention for distillation of cotton yarn pot is shown figure 2 , The equipment of the present invention is dedicated to the distillation of cotton yarn pot pot container 1 connected through the conduit 6 and the condenser 7, the inner bottom of the container 1 is placed a bracket 2, the bracket is a well-known technology, on the bracket is placed a breathable plate 3, a breathable plate 3 Place the cotton gauze tube 4 on the cotton gauze tube 4, place the cage 5 on the cotton gauze tube 4, and cover the container lid. The special distilled cotton yarn pot is connected to the condenser 7 through the tube 6 of the container lid. The bracket 2 is 8-9 cm high. The brewing raw materials do not directly contact the bottom of the container 1 to avoid paste pots and bumps. The ventilation plate 3 is provided with vents with a diameter of 1-3 cm. The bottom of the cage 5 is provided with several large vents with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com