A lap joint structure between the trim part of the front door triangular window and the sheet metal of the window frame

A technology for triangular windows and decorative parts, which is applied to vehicle parts, sealing devices, engine components, etc. It can solve the problems of exposed seam perspective, uneven surface difference, and bumping of window frame sheet metal, so as to avoid abnormal driving noise and simple structure , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and installation process, the present invention is described in further detail.

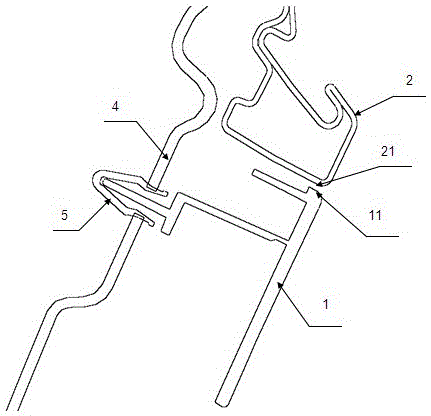

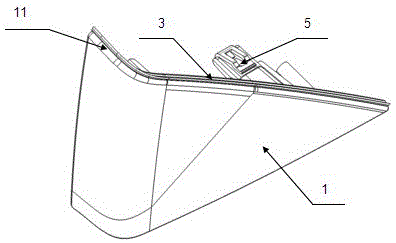

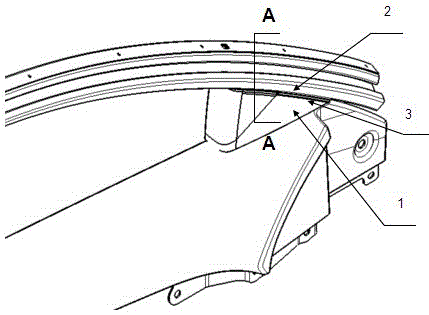

[0014] see figure 2 , image 3 , Figure 4 and Figure 5 , a car front door triangular window trim and the overlapping structure of the window frame sheet metal according to the present invention, comprising an outer lap edge 11 arranged on the front door triangular window trim 1, an outer lap edge 11 arranged on the window frame sheet metal 2 Inner overlapping edge 21; In order to overcome the defect that prior art exists, sealing strip 3 is set, and one side of this sealing strip is provided with lip 31, and the other side is provided with fixed edge 32; The inner side of described outer overlapping edge 11 is provided with There is a slot 12, which fits with the fixed side 32 of the weather strip; the lip 31 of the weather strip is in close contact with the inner lap edge 21 on the window frame sheet metal 2; The triangular window trim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com