Tire mounting and demounting machine, tire mounting method and tire demounting method

A tire loading and unloading, tire technology, applied in tire installation, tire parts, transportation and packaging, etc., can solve the problems of damage to tires, damage to the bead part of the tire, steel wire and carbon fiber breakage, etc., to prevent damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Hereinafter, the present invention will be described in more detail with reference to the drawings.

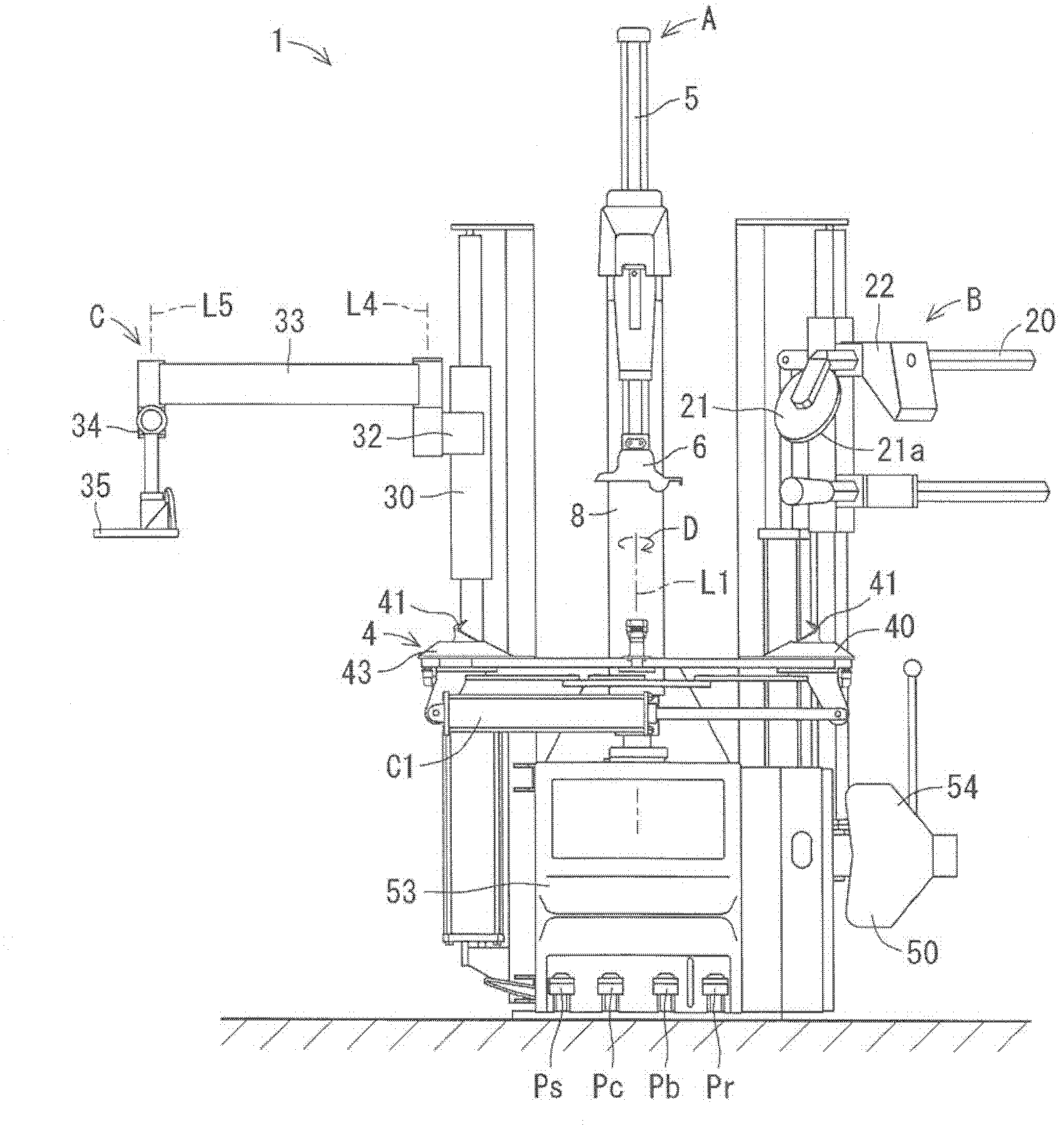

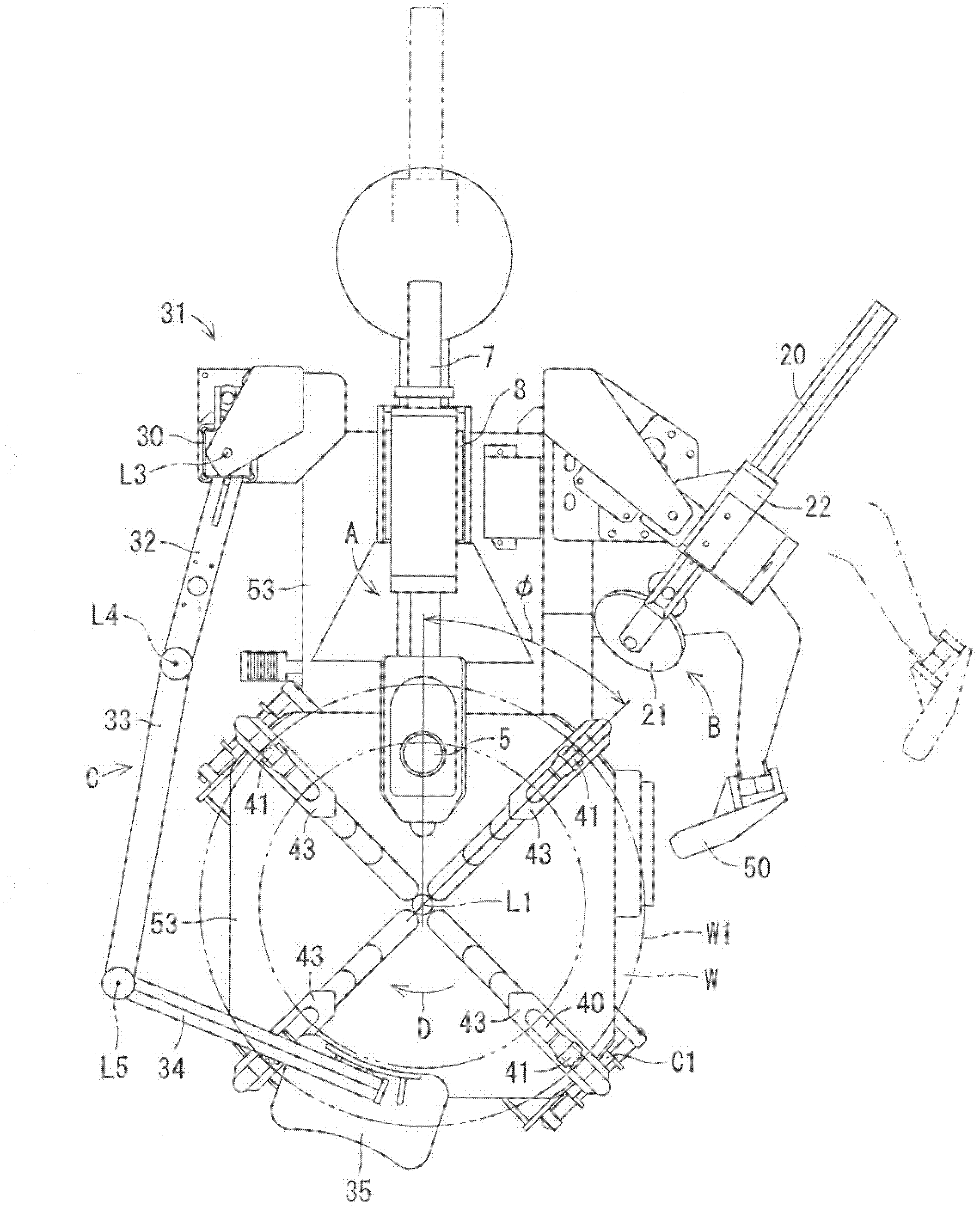

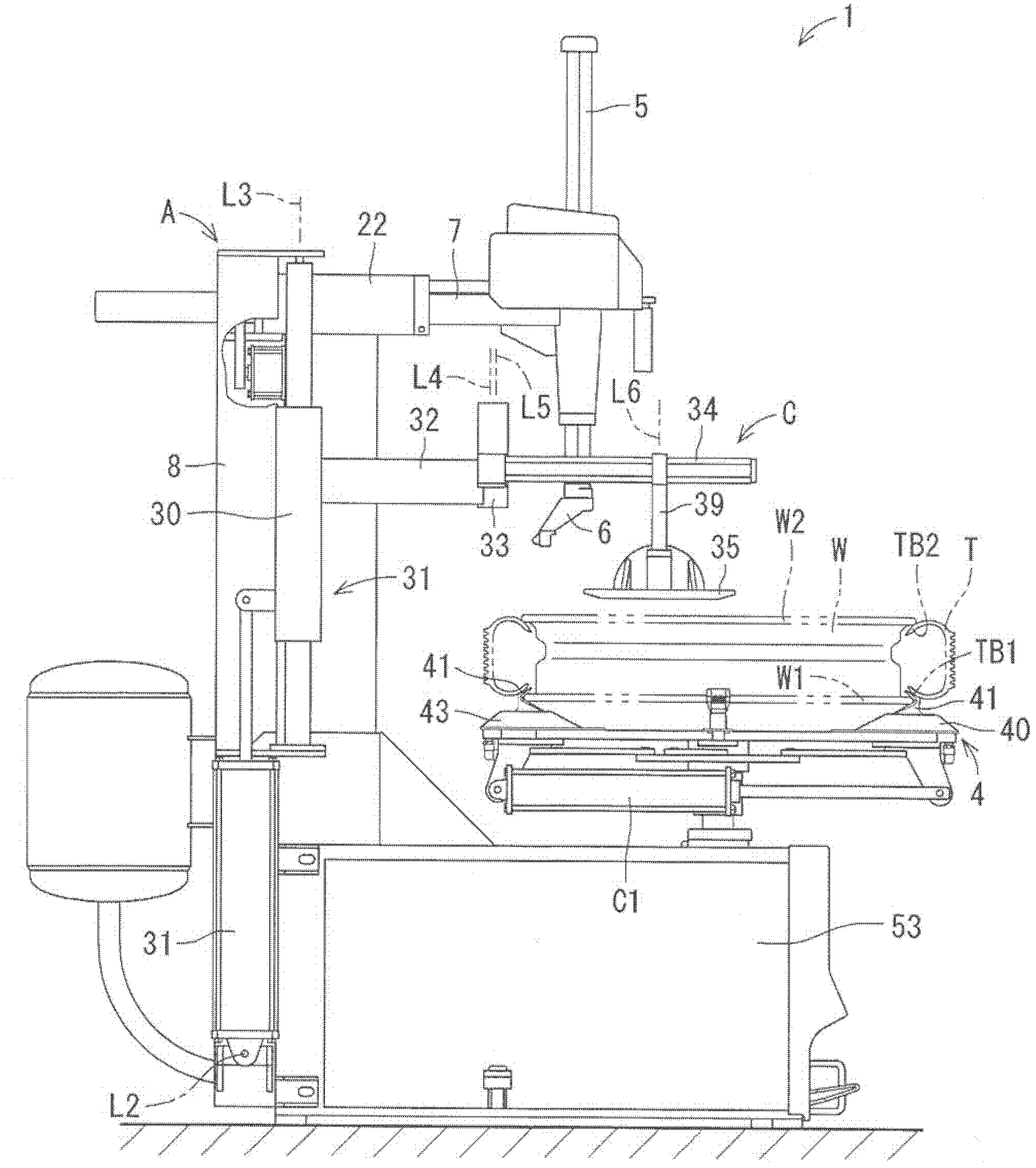

[0068] figure 1 It is a front view showing a tire loading and unloading device 1 according to an embodiment of the present invention, figure 2 for from figure 1 A top view of the tire handling device 1 seen from above, image 3 for from figure 1 The left side view of the tire handling device 1 seen from the left, Figure 4 for from figure 1 The right side view of the tire handling device 1 seen from the right side. The tire loading and unloading device 1 of the present embodiment is used to implement a tire mounting method and a tire detaching method. The tire loading and unloading device 1 of the present embodiment basically includes a bead portion guiding device A, a bead press device B, and a mount press device C. As shown in FIG.

[0069] First, the configuration of the bead portion guiding device A will be described. The bead portion guide device A include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com