One-box multi-cast plate and casting method

A casting mold and mold plate technology, which is applied in the field of casting mold plate, can solve the problems of casting blanks and casting yields that are not fixed, the pouring system of the same part is not uniform, and the size of the casting sand box is different, so as to improve the utilization rate of molding sand , simple manufacturing process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

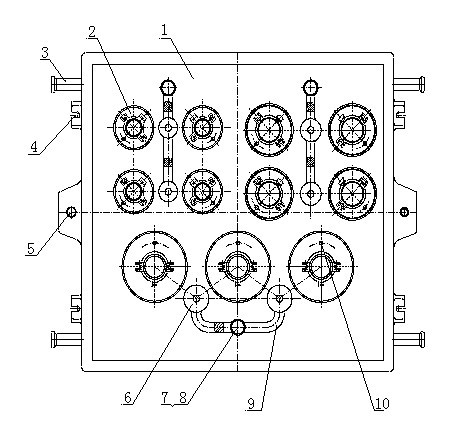

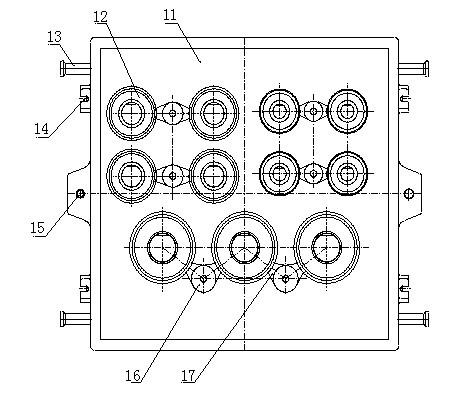

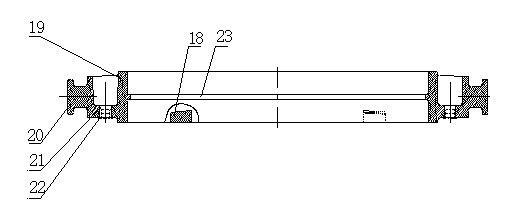

[0025] Shown in the figure, the pattern plate of the present invention comprises two parts of the upper pattern plate 1 and the lower pattern plate 11. composition.

[0026] As shown in the figure, the upper model 2 of the part and the upper sprue model are processed on the model plate of the upper mold plate, the lower model 12 of the part and the lower sprue model are processed on the model plate of the lower mold plate, the upper model 2 of the part and the lower sprue model of the part are processed on the model plate of the lower mold plate. There are more than 12 models, which are matched with each other, and the upper sprue model and the lower sprue model are matched.

[0027] The upper sprue model of the cope plate 1 includes a sprue model 7 , a sprue model 8 , a runner model 9 , a riser model 6 , and an air outlet model 10 . The lower sprue model of the lower mold plate 11 includes a riser seat model 16 and an inrunner model 17 .

[0028] The upper part model 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com