Design method for control structure of hardware-in-loop numerical control system

A technology of numerical control system and control structure, applied in general control system, control/adjustment system, instrument, etc., can solve problems such as strong dependence on hardware environment, difficulty in verifying system function, complicated development process, etc., and achieve convenient development, design and verification , to meet the test requirements, to ensure the accuracy of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

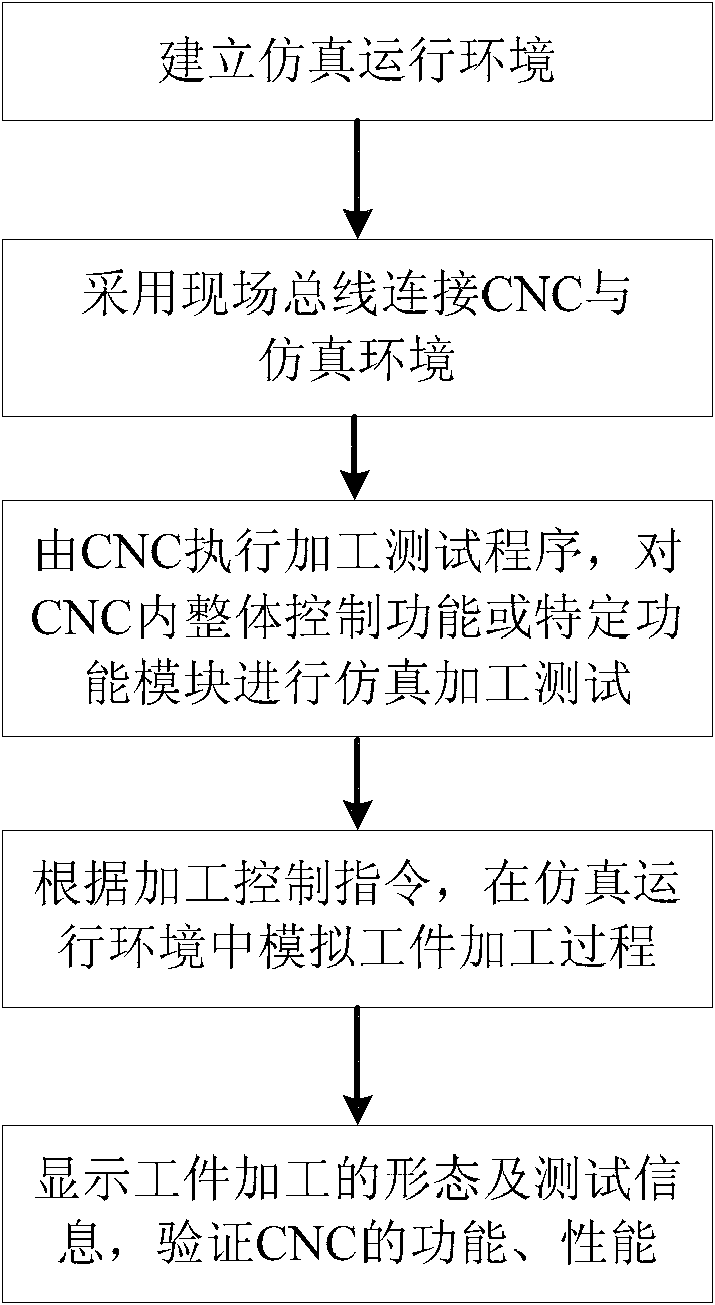

[0054] Such as image 3 As shown, it is a flow chart of the design method of the control structure of the hardware-in-the-loop numerical control system. The present invention adopts field bus technology and hardware-in-the-loop design ideas, and proposes a design method for the control structure of the hardware-in-the-loop numerical control system, which meets the application requirements such as functional module testing and overall system control function testing in the system development and design process, and improves the system The quality level and reliability of the development, reduce the risk and cost of testing, and reduce the testing time of the system.

[0055]The inventive method is a method for designing a control structure of a hardware-in-the-loop numerical control system, comprising the following steps:

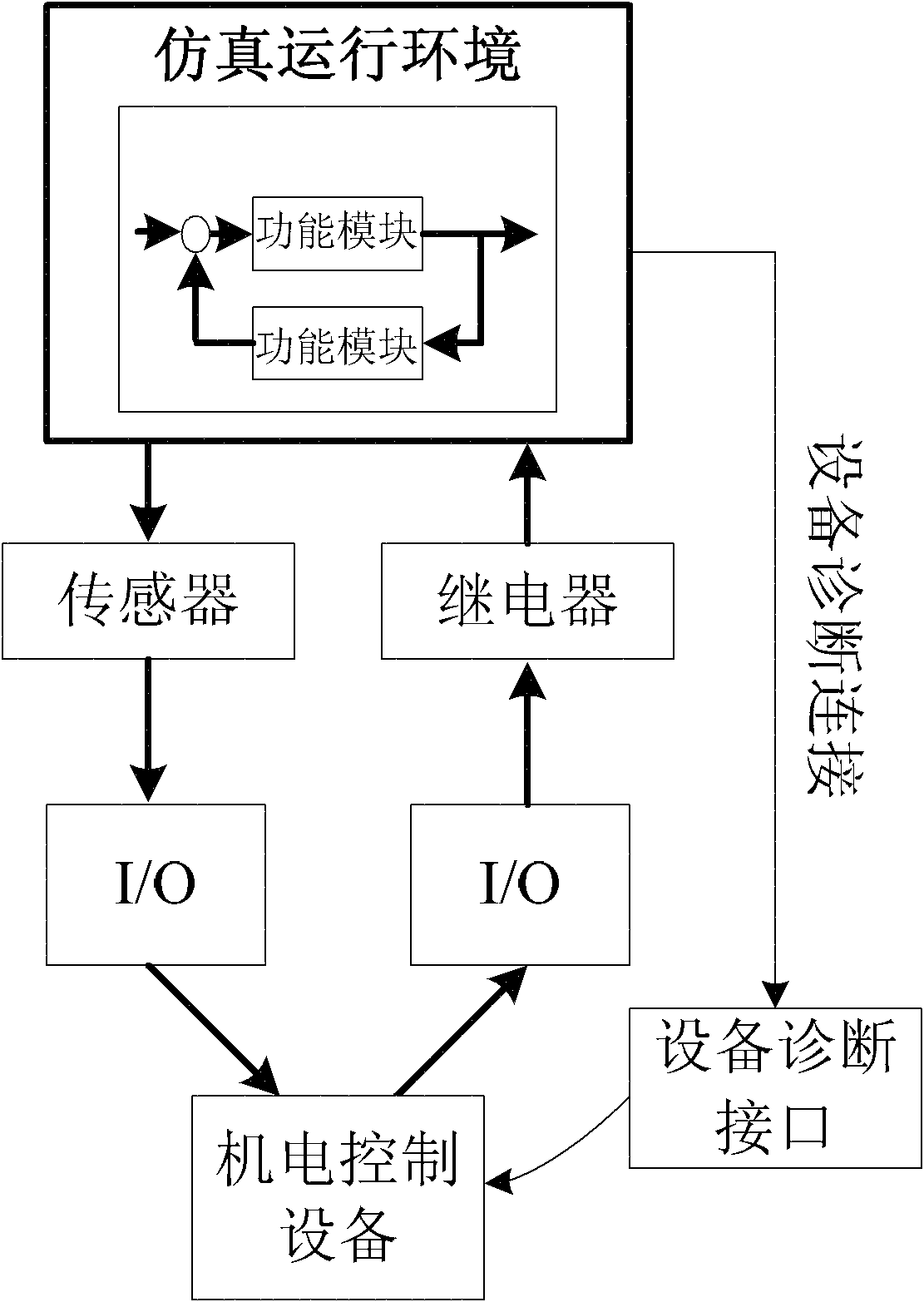

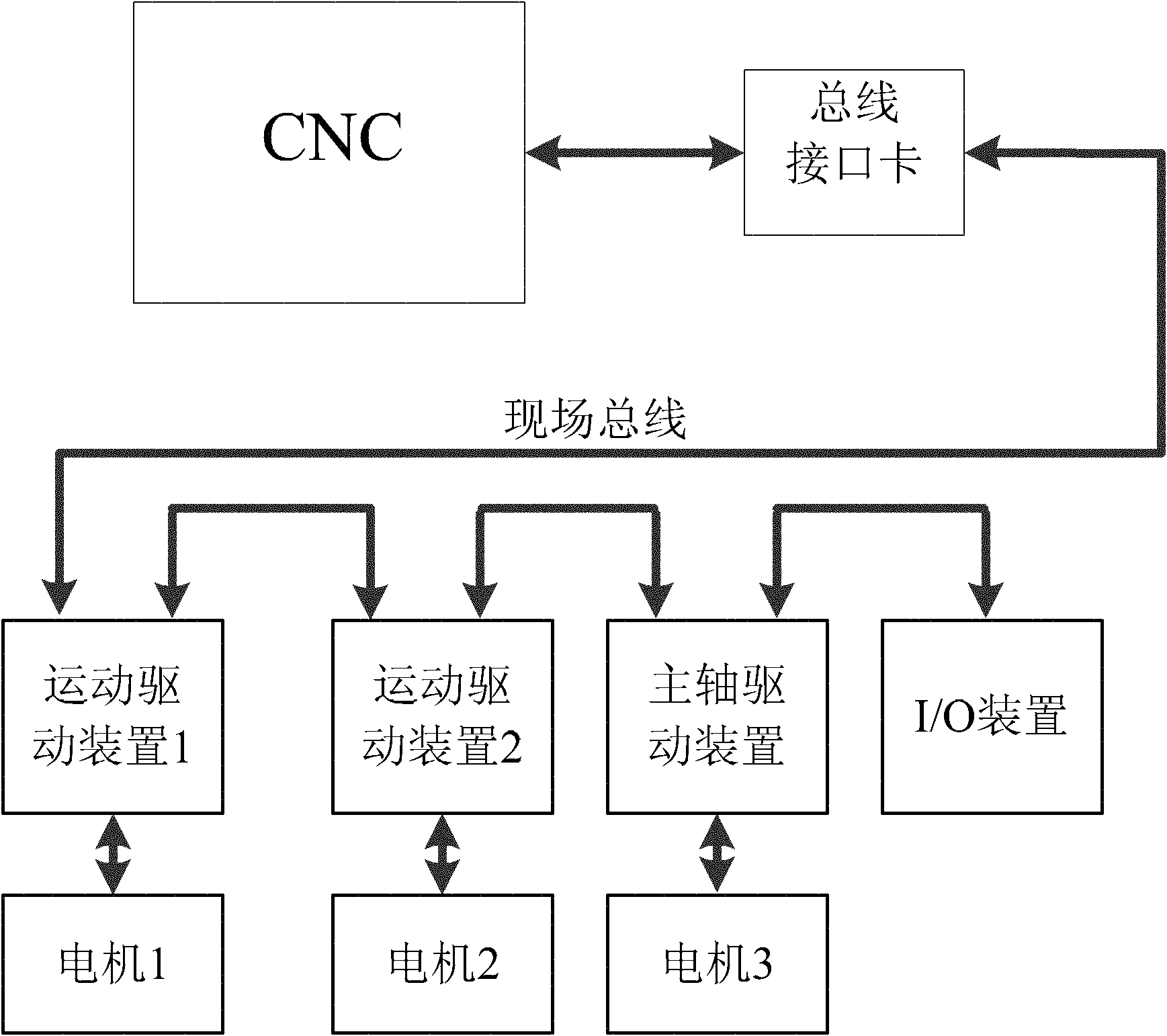

[0056] According to the functional characteristics and control requirements of the CNC system, build a CNC simulation operating environment in the CNC syst...

Embodiment 2

[0085] Such as Figure 5 As shown, it is a test structure diagram of the overall control function test of the system in the hardware-in-the-loop system. In this embodiment 2, on the basis of the simulation operation environment in embodiment 1, it is necessary to increase the corresponding test requirements according to the overall control function of CNC. The simulation function module.

[0086] Simulation processing test process of the overall control function of the system: According to the processing test requirements of the CNC system, determine the basic function modules of the CNC system, including the man-machine interface module, interpreter module, trajectory planning module, interpolation algorithm module, tool compensation module, space Kinematic transformation; execute the specified machining test program in CNC to verify the machining control process of CNC; in the simulation running environment, simulate the actual machining process of CNC machine tools accordin...

Embodiment 3

[0090] Such as Figure 6 As shown, it is a test structure diagram of the motion drive device in the hardware-in-the-loop system. The simulation operating environment can also simulate CNC to test the functional characteristics of its external equipment. The test includes the following steps:

[0091] Establish the mathematical model of CNC, and use the simulation operating environment to simulate the specified CNC;

[0092] In each communication cycle, the simulation operating environment sends control commands to the external device;

[0093] The external device executes the specified system operation according to the obtained control command, and returns the response information to the simulation operating environment;

[0094] The simulation operating environment calculates the control command of the next communication cycle according to the established mathematical model and equipment response information, and repeats the above cycle communication process until the simula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com