Detachable anchor device for cantilever section steel beam

An anchoring device and section steel technology, which is applied in the direction of house structure support, house structure support, scaffolding accessories, etc., can solve the problems of irregular bending and forming, difficult installation of I-beams, and high investment cost, and achieve good economical efficiency. Benefit and social benefit, good promotion of use value, effect of guaranteeing use safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

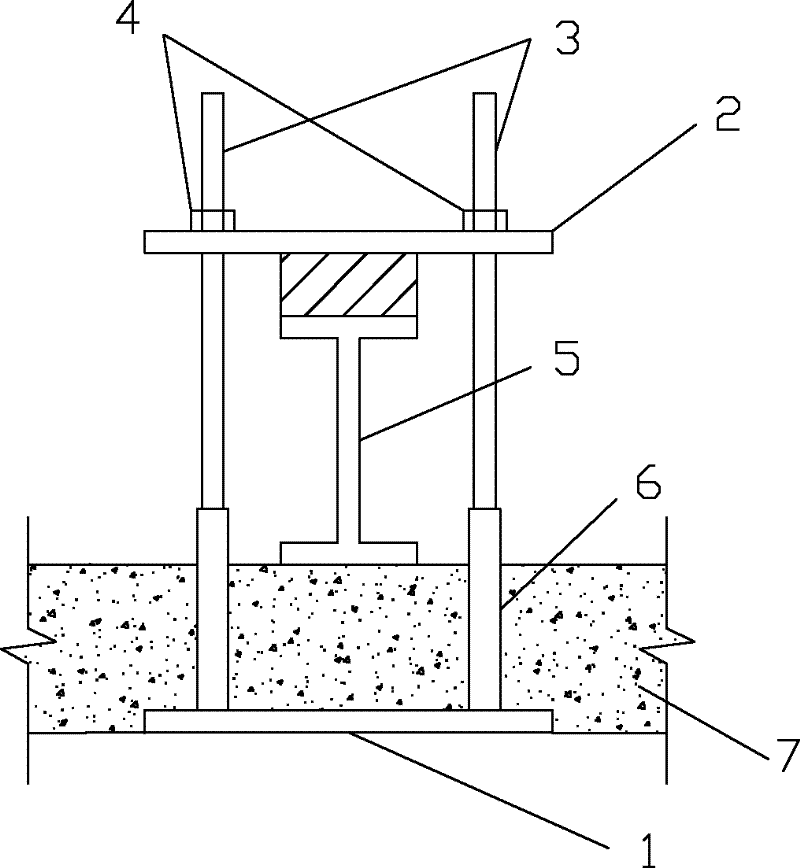

[0013] Such as figure 1 As shown, it is an embodiment of the detachable anchoring device for cantilevered steel beams of the present invention, including a base plate 1 arranged on the bottom surface of the concrete slab 7 and a pressing plate 2 for fixing the cantilevered steel beams 5 on the top surface of the concrete slab, A plastic film is laid on the bottom plate to isolate it from the concrete slab. A screw 3 is vertically fixed at the four corners of the bottom slab. The screw passes through the concrete slab and is covered with a sleeve 6 to isolate it from the concrete slab. Press the platen up and down. The casing is a PVC pipe. Both the base plate and the pressing plate are Q235 plates with a thickness of 16 mm, and both the base plate and the pressing plate are square plates with a side length of 300 mm. The bottom of the screw is welded to the four corners of the bottom plate and drilled at a distance of 50 mm from the edge. There are two pressing plates, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com