Hydraulic vertical type oil press

An oil press, vertical technology, applied in the field of hydraulic vertical oil press, can solve the problems of difficult control, high production cost, cumbersome operation, etc., and achieve the effect of easy operation, saving labor and time, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

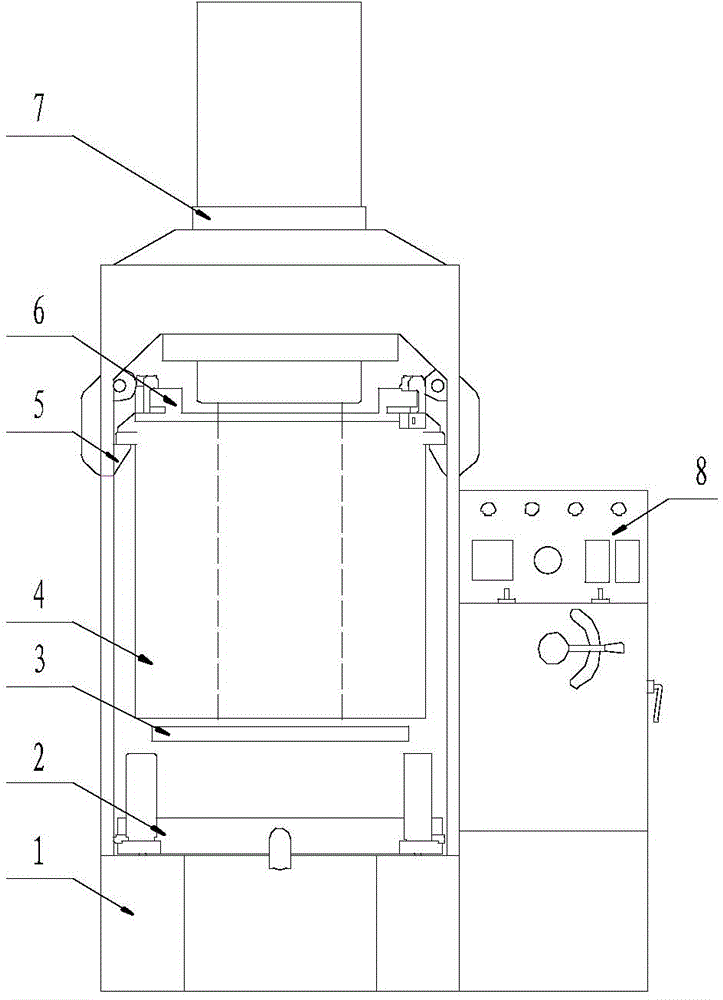

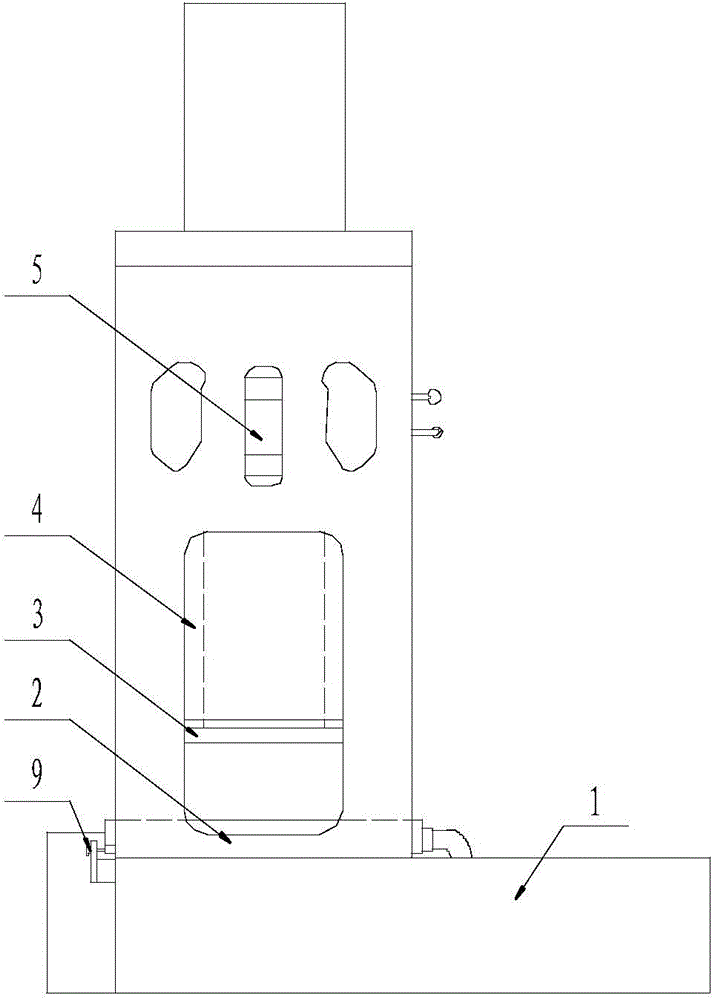

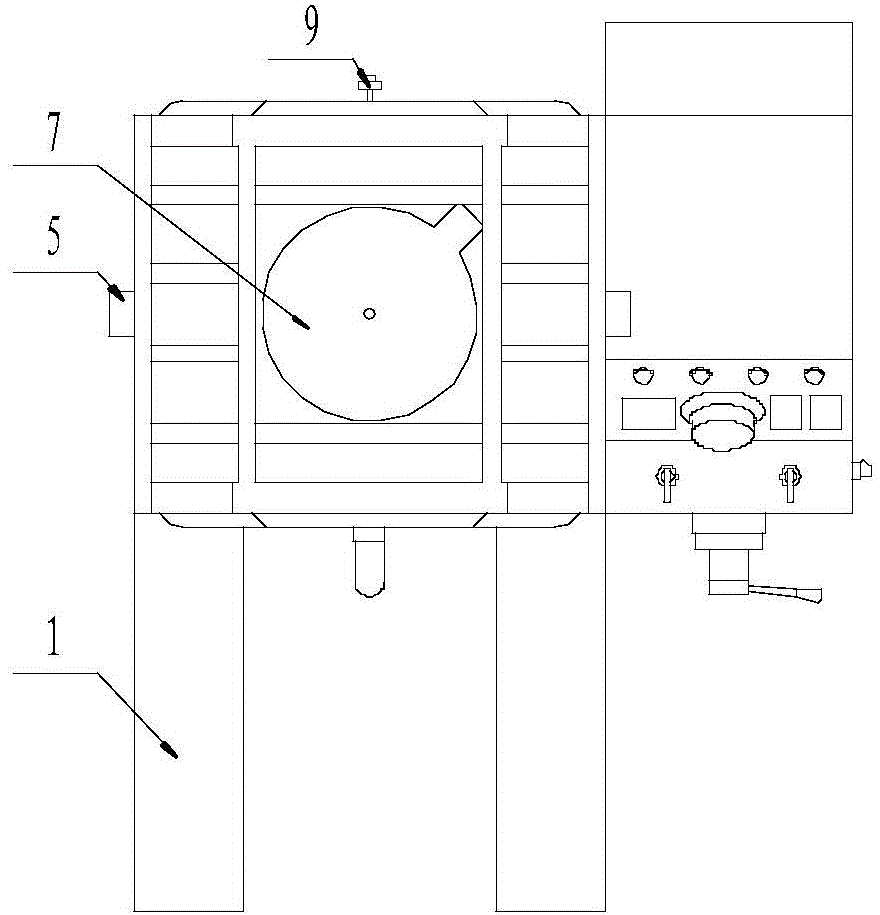

[0025] A hydraulic vertical oil press, comprising a frame 1, an oil tray 2, a squeeze cylinder 4, a hydraulic device 7, and a control box 8; the frame 1 includes a lower base 12, and the lower base 12 is provided with a limit fixing plate 13. The guide support plate A 11 and the guide support plate B 11', the guide support plate A 11 and the guide support plate B 11' are respectively provided with a limit plate 10, the limit fixed plate 13 is provided with a positioning screw 9, and the lower base 12 Side plates 14 are respectively welded on both sides, and earrings 15 are arranged on the side plates 14, and the hanging tube hook 5 is hinged on the earrings 15, and an upper machine base 16 is welded on the upper end of the side plate 14, and a travel switch 37 is arranged on the upper machine base 16. The hydraulic device 7 is installed and fixed through the upper machine base 16; the oil receiving tray 2 is installed on the lower base 12, and the oil receiving tray 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com