Resin sand processing system and work method thereof

A technology of sand treatment and resin sand, which is applied to the cleaning/processing machinery of casting mold materials, manufacturing tools, metal processing equipment, etc. Then adjust and other issues to achieve the effect of temperature adjustment, simple structure and prolonging the heat exchange time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

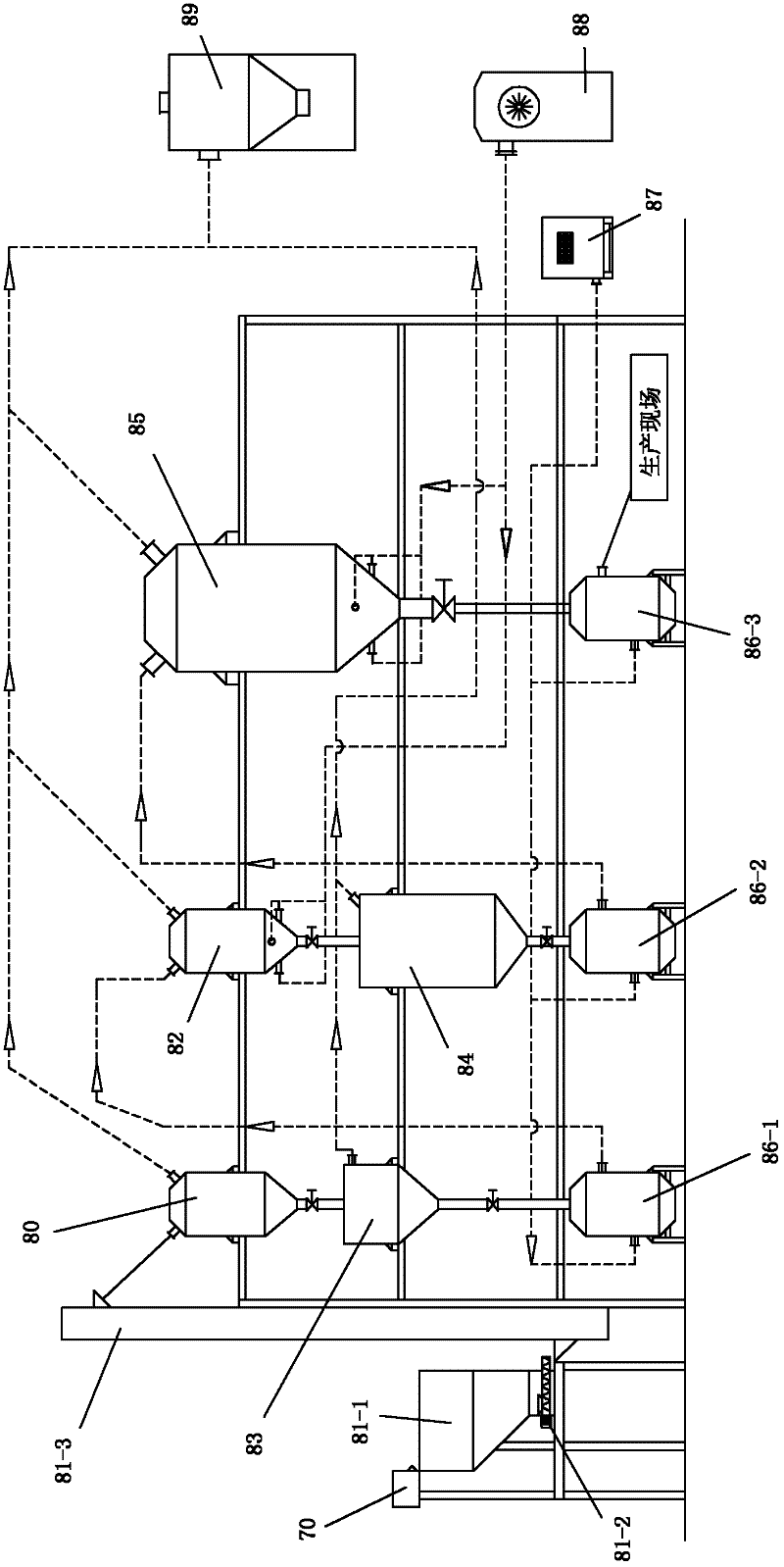

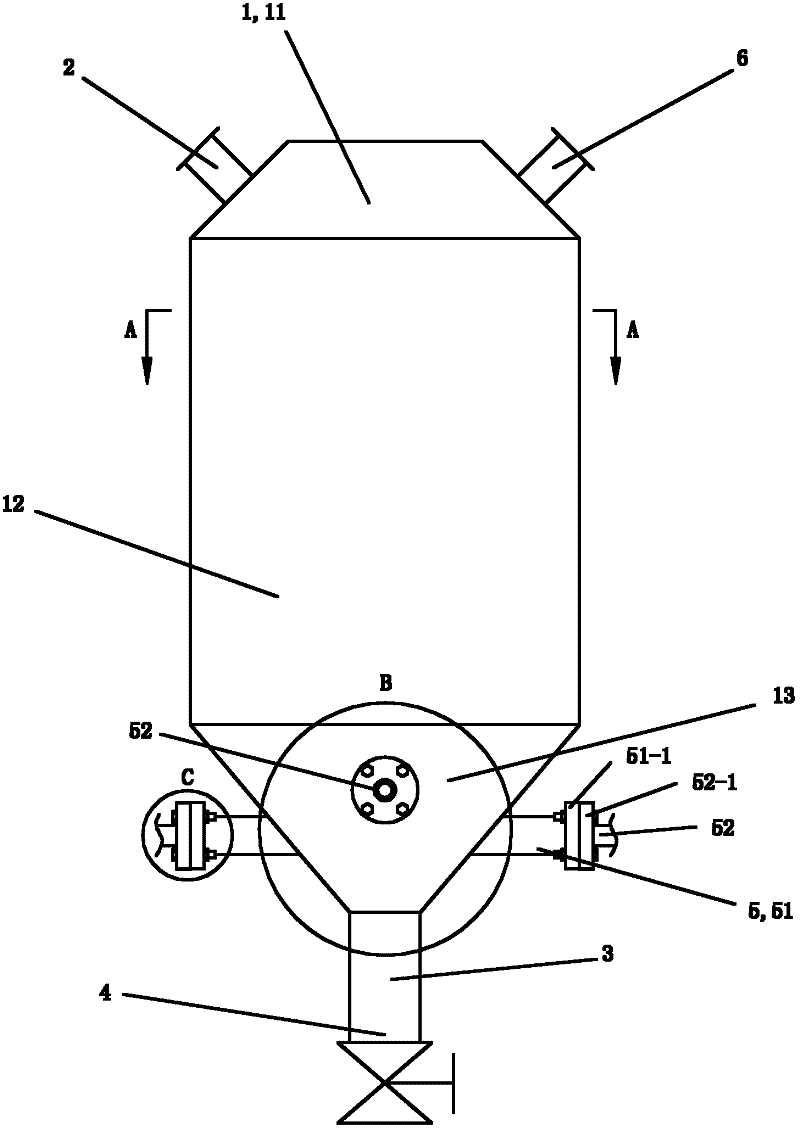

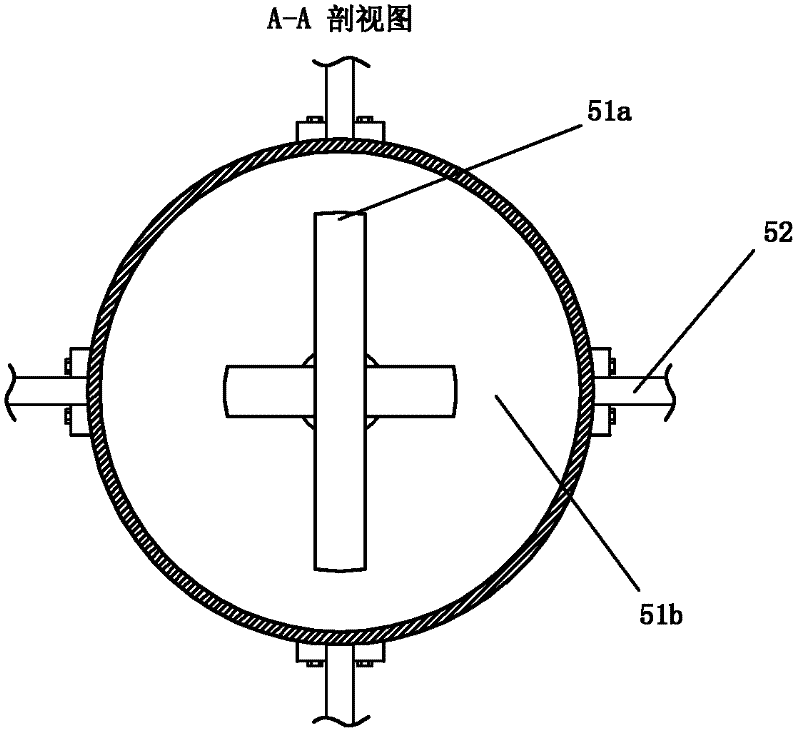

[0034] See figure 1 , the resin sand processing system of the present invention comprises a vibrating crushing regenerator 70, a feeding device 81, a sand storage device 80, a sand cooling device 82, a sand regeneration device 83, a cooling bed 84, a multifunctional silo 85, and a sand material airflow conveying Equipment 86, compressed air unit 87, air conditioning unit 88, dust removal system 89 and sand mixer. The sand cooling device 82 of the present embodiment has the same structure as the multifunctional silo 85, but the capacity is different. The sand cooling device 82 can store 20 tons to 100 tons of sand (40 tons in this embodiment), and the multifunctional silo 85 can store 100 tons to 500 tons of sand (the present embodiment is 200 tons). The sand cooling device 82 in this embodiment is also the sand storage device in the raw resin sand processing system. The multifunctional storage bin 85 of this embodiment is also the sand storehouse in the raw resin sand sand t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com